Get custom parts simply and quickly with CNC prototyping.

Provide CNC prototyping and custom parts manufacturing, supporting a seamless transition from prototype to on-demand production with flexible materials, surface finishes, and consistent quality control.

Verify Certifications On Demand:ISO 9001:2015 | IATF 16949:2016

Get a Free DFM Quote

STP I SLDPRT I IPT I PRT I SAT FLES

All uploaded content is secure and confidential.

Industry Experience

Service Company

Global Clients

Unique Parts

Our CNC Prototyping Capabilities

Our Dongguan factory supports CNC prototyping and on-demand production, with CNC machining, die casting, sheet metal fabrication, aluminum extrusion, and surface finishing. Custom parts are produced to tight tolerances with consistent quality, handling both simple and complex designs efficiently.

CNC Machining

We offer custom CNC milling and turning services for aluminum, stainless steel, and brass parts, with tolerances up to ±0.001″, fast delivery, and consistent surface quality.

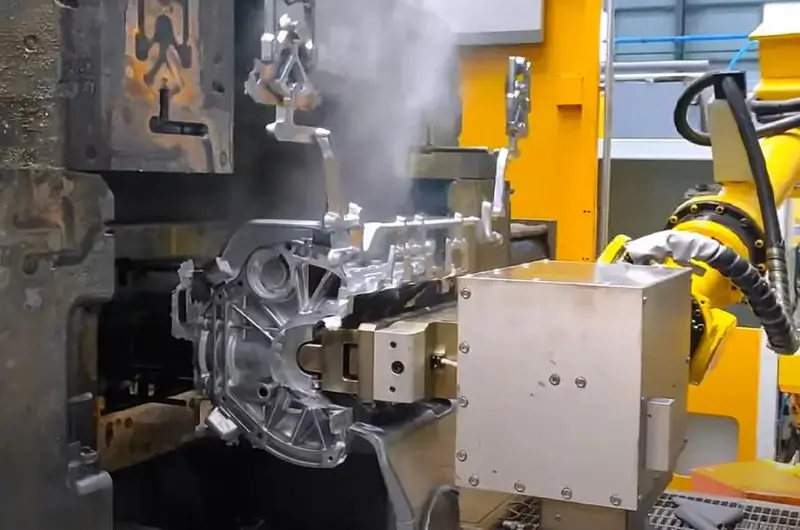

Die Casting

Comprehensive die casting solutions for functional and cosmetic components, engineered to meet exact industry standards with superior quality, performance, and reliable results.

Sheet Metal Fabrication

Comprehensive sheet metal fabrication, including laser cutting, CNC bending, welding, and assembly, ensuring precision, consistency, and strength.

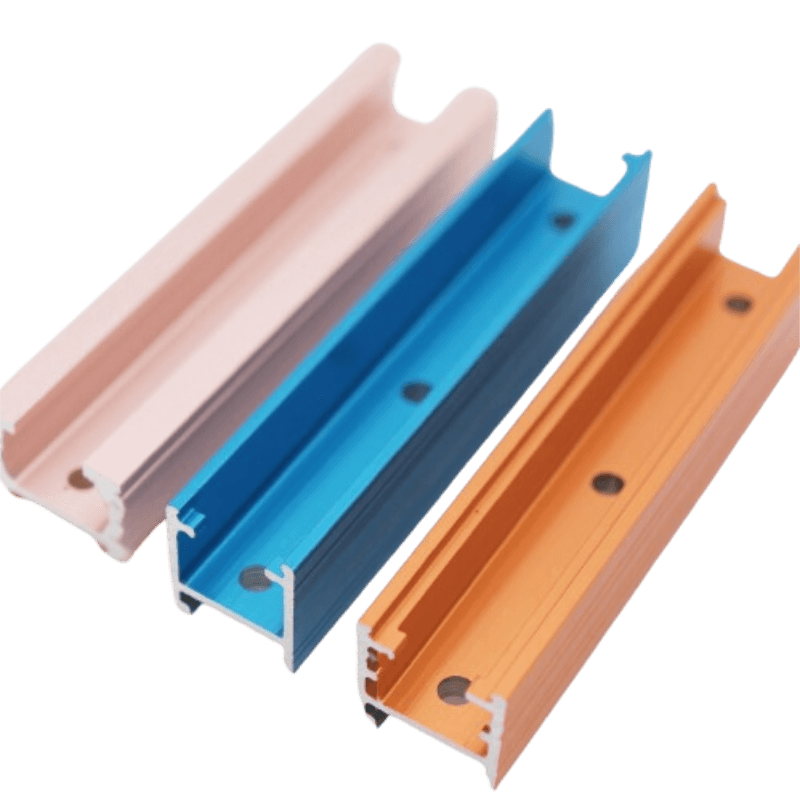

Extrusion

Providing high-quality, cost-effective aluminum extrusion parts with precise dimensions, consistent surfaces, and reliable performance.

Surface Treatment

Comprehensive surface finishing solutions for custom parts, combining durability, functionality, and aesthetic appeal.

Your Trusted Custom Parts Manufacturing Partner

Unlike many traditional precision trading companies, ZH Precision has provided complete manufacturing solutions since 2009, from CNC prototyping to batch production. Our factory, equipped with advanced machinery and an experienced engineering team, follows multiple international quality standards to ensure every part meets high design and quality requirements. We provide one-stop services, including machining, surface finishing, assembly, and packaging. Efficient workflows and a global logistics network ensure custom parts are delivered to North America and Europe within 5–10 days, quickly, reliably, and with consistent precision.

Design and Engineering Support

ZH Precision provides expert design and engineering support for CNC prototyping, on-demand manufacturing, and custom parts production. Our experienced team works closely with you to optimize designs for manufacturability (DFM), minimize production risks, and ensure consistent quality at every stage. From initial prototyping to full-scale custom parts manufacturing, we deliver practical engineering solutions that save time, reduce costs, and ensure reliable, high-quality results throughout the entire process.

- DFM Optimization – Designs optimized for manufacturability

- Material & Process Guidance – Expert material and process advice

- Tolerance & Quality – Ensure precision and consistency

- Transparent Pricing – Clear, upfront pricing with no hidden fees.

- After-Sales Support – Free replacement for defective products.

From CNC Prototyping To On-Demand Manufacturing

Whether it’s a single CNC prototype or a full production run, ZH Precision delivers scalable, on-demand manufacturing solutions tailored to your needs. Quickly validate designs, test functionality, and move seamlessly from prototypes to small-batch or large-volume custom parts production with reliable quality and consistent results.

Rapid Prototyping

Produce CNC prototypes quickly to validate design intent, test fit and performance, and reduce development risk.

Low-Volume Manufacturing

Efficient small-batch production of custom parts for pilot runs, testing, or early market entry, balancing cost control with consistent quality.

On-Demand Manufacturing

Flexible production of custom CNC parts, from single units to larger volumes, ensuring reliable supply without overstocking.

Get a free DFM assessment

Our engineers can evaluate your design and recommend the most cost-effective solution — from CNC machining and die casting to sheet metal fabrication and aluminum extrusion.

Full-Process Quality Control

At ZH Precision, we ensure quality at every stage of CNC prototyping and custom parts production. Our quality control lab is equipped with advanced testing equipment, including CMMs, Spectrometers, and X-ray Analyzers. With an ISO 9001:2015 certified system, we guarantee consistent control, reliable performance, and precision for on-demand manufacturing.

1. In-Process Quality Monitoring

Critical dimensions of CNC and custom parts are checked via scheduled IPQC inspections to maintain process stability.

2. 100% Final Inspection & Secure Packaging

All parts undergo full visual and dimensional inspection, followed by specification-compliant packaging for safe delivery.

3. Quality Documentation & Traceability

FAI reports, full-dimension inspection data, and material certifications support traceability for CNC and on-demand parts.

Our Success Stories

Explore how ZH Precision has delivered CNC prototyping and on-demand custom parts solutions for clients across aerospace, communications, medical, and industrial sectors. Discover projects highlighting precision, reliability, and fast turnaround.

Aluminum Die-Cast Server Mounting Bracket

- Manufacturing Process: Aluminum die casting + Drilling

This project was developed in collaboration with Oracle, demonstrating the combined capabilities of ZH Precision’s die casting technology, engineering expertise, and manufacturing execution. Through close technical coordination and disciplined process control, we delivered a solution that met strict requirements for structural integrity, dimensional accuracy, and production consistency.

How to Work with ZH Precision

Share your CAD files and receive fast DFM feedback from our professional engineering team. We provide guidance for CNC prototyping, on-demand manufacturing, and custom parts production, recommending the most cost-effective solutions for your project.

Submit Your Design

Send us your CAD drawings or 3D files. Our engineers will review your requirements and prepare a detailed quotation promptly.

Receive Quote & DFM Feedback

We provide a clear quote and professional DFM (Design for Manufacturability) report to ensure your design is optimized for production.

Confirm & Start Production

Once you approve the quote, we begin manufacturing your parts and keep you updated throughout the process until delivery.

Frequently Asked Questions

A: CNC prototyping is the process of producing high-precision prototypes and custom parts using CNC milling, turning, and multi-axis machining. It helps validate designs and prepare for on-demand manufacturing.

Learn more in our detailed guide: What Is CNC Prototyping?

A: ZH Precision stands out with our state-of-the-art CNC machining workshop, equipped with over 30 advanced machines, including 3-, 4-, and 5-axis CNC mills, precision turning centers, and Swiss-style lathes. In addition to cutting-edge equipment, we offer complete post-processing services, including surface finishing, assembly, and packaging. This full-service capability allows us to handle complex projects from start to finish, ensuring high quality, precision, and reliability. By streamlining production, we help increase efficiency, reduce costs, and simplify your supply chain.

A: CNC prototyping produces parts from solid metal or plastic with high accuracy and production-level material properties, making it ideal for functional testing and low-volume production.

3D printing builds parts layer by layer and is better suited for early-stage design validation and visual models.

Learn more in CNC Prototyping vs 3D Printing

A: Our CNC prototyping and on-demand manufacturing services support aluminum, stainless steel, brass, magnesium, zinc, and other metals suitable for precision parts.

A: The CNC prototyping process at ZH Precision covers every step from design to delivery. Engineers review CAD files for manufacturability, program CNC machines for precise milling and turning, apply required surface treatments, and perform full inspections to ensure dimensional accuracy and finish quality. Finished prototypes are securely packaged and delivered, ready for functional testing or small-batch production. Learn more: CNC Prototyping Process: From Design to Delivery

A: Yes, we take the confidentiality of our clients' intellectual property and business information very seriously. We are happy to sign a Non-Disclosure Agreement (NDA) before proceeding with any cooperation, if required. This ensures that your designs, data, and any other sensitive information will be kept strictly confidential. Please contact us to discuss specific confidentiality terms and partnership details.

Manufacturing Resources

How to Calculate Die Casting Cost

Die casting costs directly influence product pricing, profit margins, and overall project feasibility. For engineers developing new products and sourcing

Die Casting Pros and Cons: A Detailed Guide

Choosing the right manufacturing process can make or break a project. Die casting is widely used in automotive, electronics, hardware,

Die Casting General Overview: Process, Materials & Applications

In today’s manufacturing landscape, the demand for high-precision metal components has never been higher. Whether it’s automotive, electronics, industrial machinery,