Aerospace Industry

Full-scale manufacturing solutions for aerospace components, delivering prototyping, low-volume, and mass-production parts with precise tolerances and dependable quality.

- ISO 9001 Certified Manufacturing

- Instant Quoting & DFM Feedback

- Complete Finishing, Joining & Assembly Services

- Industry-Experienced Engineering Support

Verify Certifications On Demand:ISO 9001:2015 | IATF 16949:2016

Home » Aerospace

Aerospace Manufacturing Challenges

Aerospace components often feature thin walls, complex geometries, and tight tolerances, requiring precise material performance, machining stability, and process control. Residual stress, thermal distortion, or process variation can surface during assembly or testing, causing rework and schedule risk. Ensuring consistency from prototype to production is a core challenge.

Manufacturers address this by performing early DFM evaluations, optimizing machining strategies and stress management, and applying rigorous in-process and final inspections, ensuring reliable, consistent, production-ready aerospace parts.

Why Choose Us For Aerospace Parts Manufacturing?

Manufacturing aerospace prototypes demands absolute precision, consistent quality, and strict compliance with industry standards. With years of experience supporting aerospace projects, ZH Precision delivers reliable prototypes ranging from simple components to highly complex geometries. Each part undergoes rigorous inspection and validation to ensure performance and accuracy.

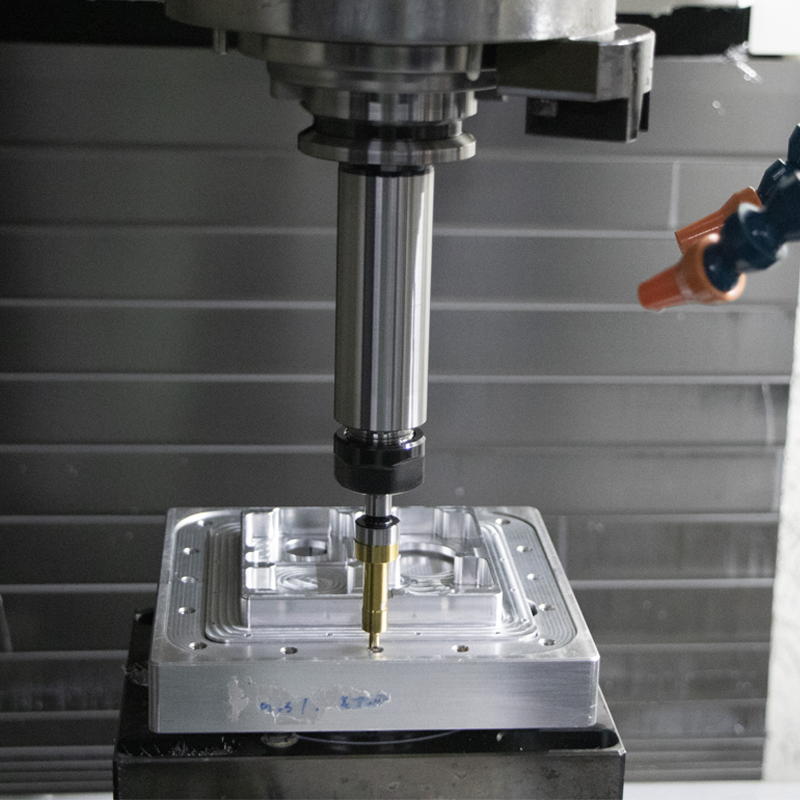

Precise Tolerances

Our advanced manufacturing ensures each component meets exacting precision standards. We can achieve tolerances down to ±0.005 mm, making sure every part meets your specifications and quality requirements.

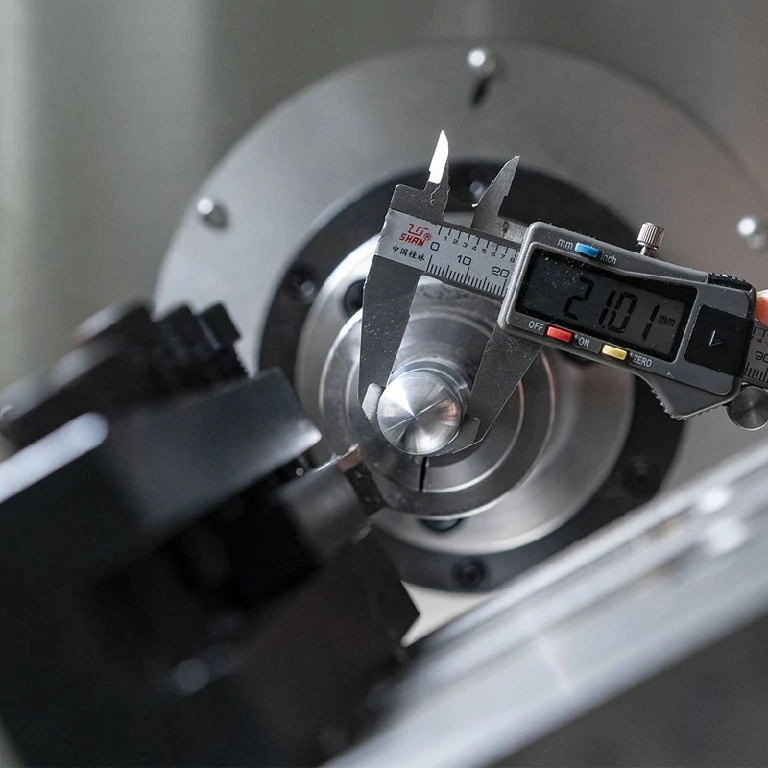

Quality Assurance

We follow ISO-certified quality systems and track every step of production with advanced inspection equipment. All parts are 100% inspected to guarantee consistent, high-quality components.

Engineering Support

Our engineers have extensive aerospace experience and provide hands-on support with design validation, material selection, and production planning.

Aerospace Prototyping with ZH Precision

Our aerospace prototyping process enables early design validation and functional testing for critical components. CNC prototypes can be delivered in just 3–5 days, helping engineers verify geometry, fit, and performance before moving to full production.

Rapid Prototyping

Develop high-fidelity aerospace prototypes for early-stage design verification and risk reduction. At this stage, we manufacture prototypes strictly based on your engineering drawings and technical requirements, focusing on structural integrity, material behavior, and manufacturability. Depending on program needs, prototype parts can be produced using aerospace-relevant materials and cost-efficient processes that closely simulate final production parts.

- Rapid material and structural design iterations

- High-accuracy prototypes for complex aerospace geometries

- Prototype parts closely matching final aerospace components

Engineering Validation and Testing

Produce precise functional aerospace prototypes to validate engineering performance and critical design assumptions. EVT focuses on identifying structural, thermal, and mechanical risks through multiple prototype iterations. Our engineering team supports design optimization to ensure parts meet aerospace performance requirements and functional targets.

- Precision manufacturing for functional aerospace components

- Engineering-driven DFM and design optimization support

- Material and structural validation for aerospace applications

Design Validation and Testing

Validate final part functionality, mechanical performance, and appearance using production-intent materials and surface finishes. This stage ensures the component meets aerospace design expectations in terms of fit, form, surface quality, and durability. We support a wide range of aerospace-approved materials and finishing processes to meet program-specific requirements.

- Production-intent aerospace parts for system-level testing

- Verification of performance, fit, and appearance

- Aerospace-grade surface finishes and durability validation

Production Validation and Testing

Prepare aerospace components for full-scale production using production-grade processes, tooling, and quality control systems. PVT ensures manufacturing consistency, process stability, and repeatability before mass production. Final design and process adjustments are completed to guarantee reliable, scalable manufacturing.

- Production-quality aerospace parts with short lead times

- Manufacturing process verification and repeatability validation

- Low-volume aerospace tooling and pilot production support

- Functional verification of production-ready components

Mass Production

Transition smoothly from validation to full-scale production of aerospace end-use components. We manage production with strict quality control, aerospace manufacturing standards, and process consistency. Our advanced manufacturing capabilities and experienced engineering team ensure stable production yields, tight tolerances, and on-time delivery while optimizing cost and lead time.

- High-quality aerospace-grade end-use parts

- Tight tolerances for precision aerospace components

- Secondary operations for functional and surface requirements

- Rigorous inspection and quality assurance throughout production

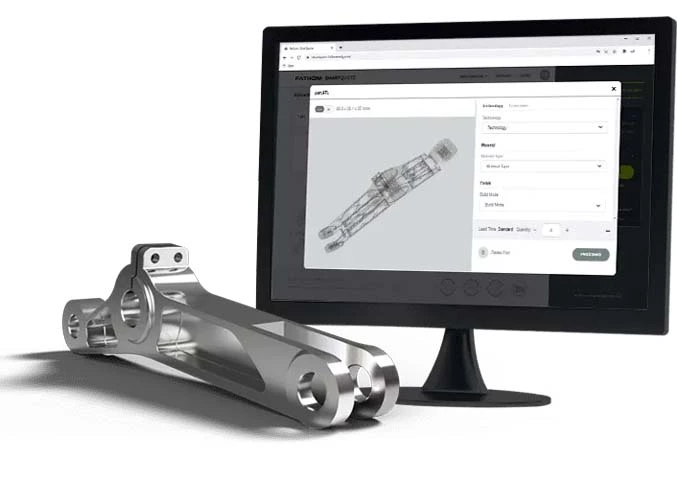

Get a free DFM assessment

Our engineers can evaluate your design and recommend the most cost-effective solution — from CNC machining and die casting to sheet metal fabrication and aluminum extrusion.

Manufacturing Solutions for Aerospace Parts

We provide precision prototyping and manufacturing solutions for aerospace components, delivering complex parts with exceptional accuracy, reliability, and performance.

CNC Machining

High-precision brackets and structural components with tight tolerances and reliable performance.

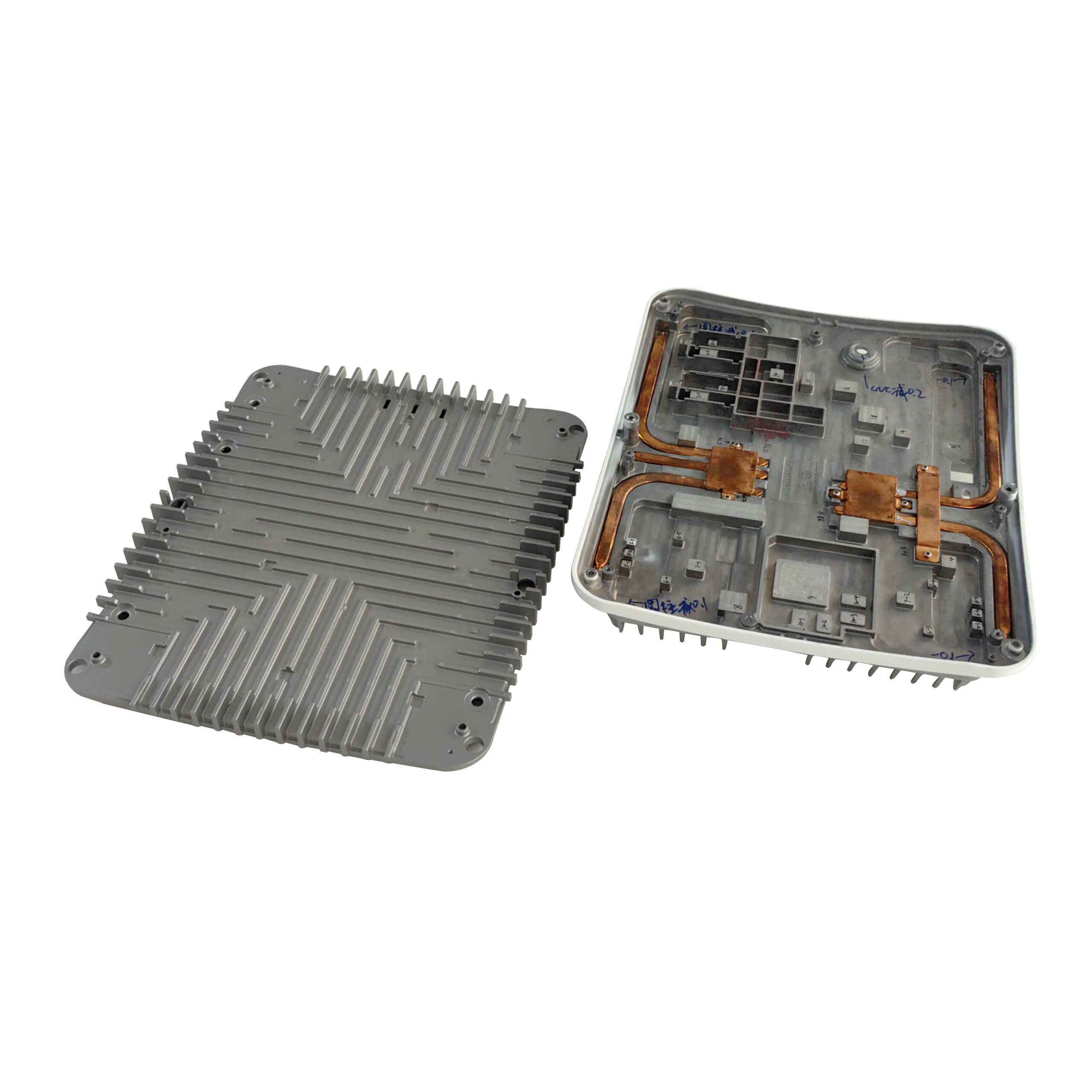

Die casting

Aluminum housings and structural parts with consistent quality and complex geometry.

Sheet Metal Fabrication

Lightweight enclosures, covers, and formed components for avionics and structural assemblies.

Aluminum Extrusion

Long, lightweight profiles for frames, rails, and support structures with uniform cross-sections.

Materials & Surface Finishes

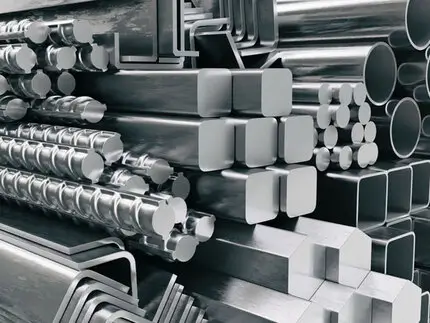

Materials

We provide a wide range of materials, including metals, plastics, and composites.

Surface Treatment

We offer superior surface finishes that enhance part durability and aesthetics for applications requiring smooth or textured surfaces.

What Aerospace Parts Can ZH Precision Manufacture?

ZH Precision is a leading manufacturer of high-precision aerospace parts, specializing in critical rotating parts, structural elements, and fluid systems. Our advanced manufacturing processes ensure the production of reliable, high-performance parts for the aerospace industry.

Trusted by Leading Global OEMs

ZH Precision is a trusted manufacturing partner for leading global OEMs, including Foxconn, Airspan, Oracle, Juniper, Alnan, and SAGERAN. With proven machining capabilities, consistent product quality, and responsive engineering support, we are a reliable supplier of aerospace component manufacturing.

Extensive Industry Experience

Aerospace Industry FAQs

A. We produce a wide range of custom metal parts for aerospace applications, including structural frames, brackets, shafts, housings, and precision mounts. These components are engineered to withstand extreme conditions, vibration, and high loads.

A. CNC prototyping allows engineers to validate designs, test fit and assembly, and ensure functional performance before full-scale production. This reduces costly design errors and ensures precise, high-quality components for aircraft and spacecraft systems.

3. We specialize in metals commonly used in aerospace, such as aluminum alloys, titanium, stainless steel, copper, and nickel alloys. These materials are selected for strength, weight optimization, and corrosion resistance.

A:Yes, we support low-volume production runs, prototypes, and custom parts. Our CNC and precision machining capabilities ensure tight tolerances and consistent quality, even for small or specialized orders.

A: All parts undergo strict quality control, including dimensional inspection, material verification, and functional testing. We adhere to industry standards to guarantee that aerospace components meet performance, safety, and reliability requirements.