Custom Aluminum Die Casting Services

We offer custom aluminum die casting supported by CNC rapid prototyping, allowing you to validate designs, check fit, and test functionality before tooling, reducing risk and accelerating development.

- Flexible Low-Volume Production

- Expert Engineering Support

- Cost-effective Solutions

Verify Certifications On Demand:ISO 9001:2015 | IATF 16949:2016

Home » Aluminum die casting

Get a Free DFM Quote

STP I SLDPRT I IPT I PRT I SAT FLES

All uploaded content is secure and confidential.

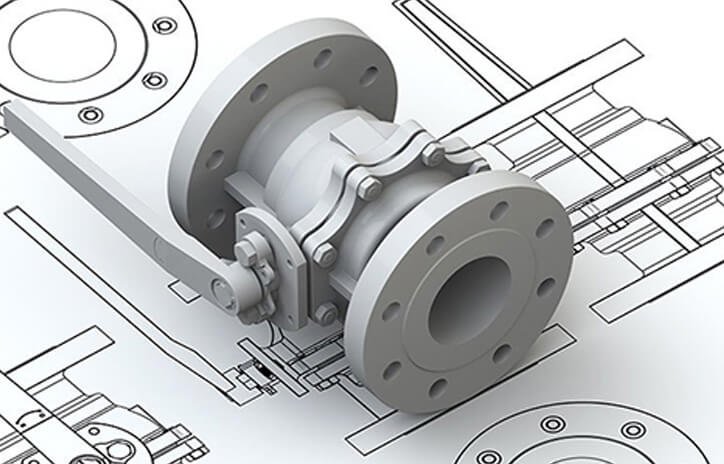

Aluminum Die Casting Solutions with ZH Precision

ZH Precision has 15 years of experience in aluminum die casting, providing reliable, high-quality solutions for your projects. We are certified to ISO 9001:2015 and IATF 16949:2016, ensuring all production processes are strictly controlled. Our experienced engineering team offers full project support, including rapid prototyping, DFM evaluation, and mold design, guiding your project smoothly from concept and sample approval to mass production and delivering durable, cost-effective, and consistently high-quality components. ZH Precision is your trusted aluminum die casting manufacturer.

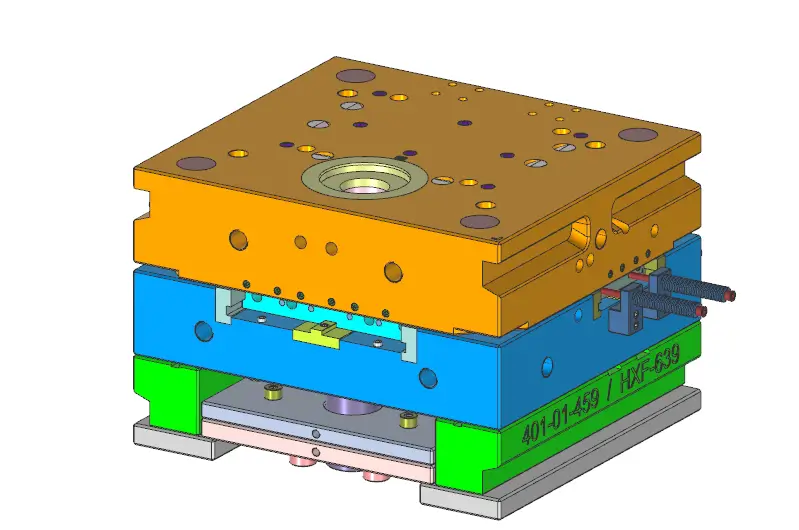

One-Stop Aluminum Die Casting Manufacturing Solution

Our one-stop aluminum die casting solution integrates DFM review, tooling, casting, machining, surface finishing, and final inspection under one quality-controlled system. By eliminating multi-supplier coordination, we reduce dimensional mismatch, shorten overall lead time, and improve production stability from prototype validation to mass production.

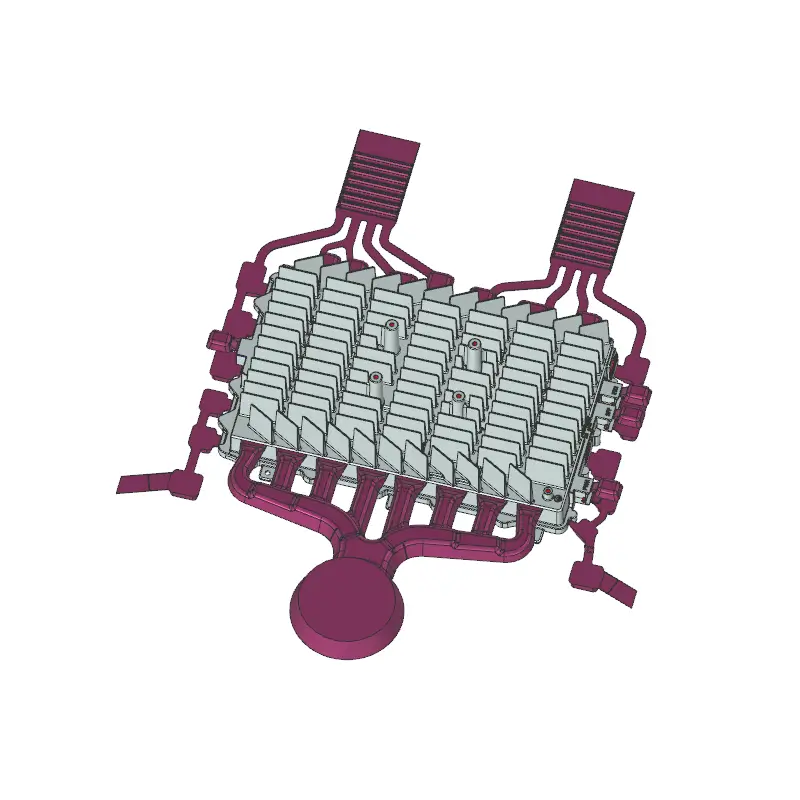

Mold Design & Manufacturing

Die Casting Production

Secondary Processing

CNC Precision Machining

Surface Treatment

100% Full Inspection

Aluminum Die Casting Capabilities

We provide precise and stable aluminum alloy die casting for components with complex geometries, thin-wall structures, and high strength requirements. Our capabilities support a wide range of part sizes and production volumes, ensuring consistent dimensional accuracy and compliance with ISO/IATF-certified quality standards.

| Description | Specification |

|---|---|

| Maximum Part Weight | 18 kg |

| Minimum Part Weight | 0.005 kg |

| Minimum Part Size | ∅15 mm × 3 mm |

| Maximum Part Size | 350 mm × 720 mm |

| Minimum Wall Thickness | 0.8 mm |

| Maximum Wall Thickness | 15 mm |

Aluminum Die Casting Quality Control

Our Quality Assurance Lab maintains strict control over all stages of aluminum die casting—from material verification and mold-flow analysis to X-ray inspection, air-tightness testing, and full-dimensional CMM reporting. Our quality engineering team continuously improves inspection protocols to ensure stable and reliable results for every batch.

PO Consistency & DFM Review

100% DFM review of part geometry to ensure both parties align on final specifications before tooling kick-off.

Risk Control Through Mold-Flow Simulation

Full mold-flow analysis for every project to eliminate potential casting defects before mold manufacturing begins.

Material Verification

Material density and composition testing to ensure stable alloy quality and prevent issues such as peeling or bulging.

X-Ray Internal Defect Inspection

X-ray inspection of critical components to detect internal porosity and shrinkage, reducing machining risks and scrap rates.

Helium Leak Testing

Helium-based air-tightness testing available for parts requiring high sealing performance.

Comprehensive Inspection Reports

3D CMM full-dimension reports and surface treatment weather-resistance test reports provided upon request.

Aluminum Die Casting for Electric Vehicle Battery Housing

Control Focus:

We maintain precise control over mold thermal balance, cavity vacuum, and high-pressure intensification to eliminate porosity and ensure leak-proof integrity. Focus is on achieving uniform wall thickness, minimal warpage, and consistent mechanical properties for structural safety, crash performance, and effective thermal management in battery systems.

Process Technology:

Process Technology:

Using high-vacuum die casting, the cavity is evacuated below 50 mbar before injection. A multi-phase fill profile ensures complete, laminar flow in thin walls, followed by immediate high-pressure intensification (>800 bar). Conformal cooling and local squeeze pins promote uniform solidification, yielding dense, high-integrity castings ready for precision machining and sealing.

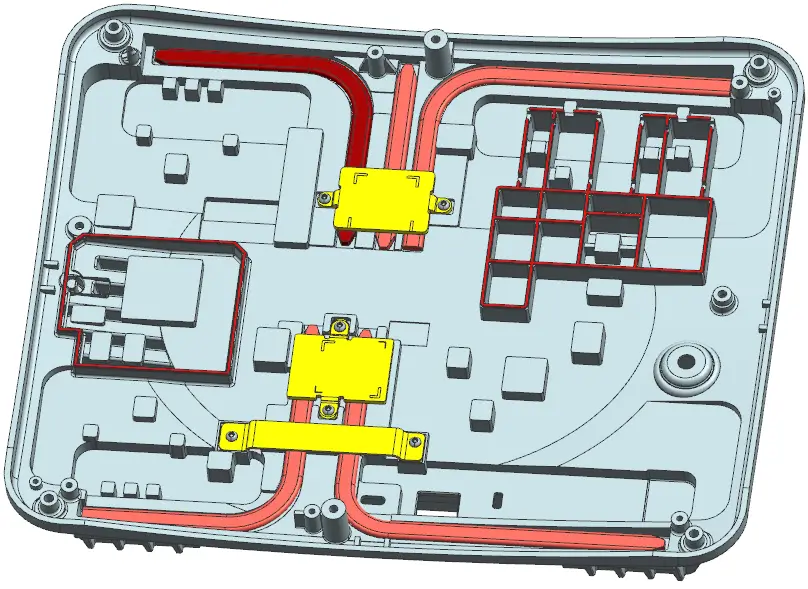

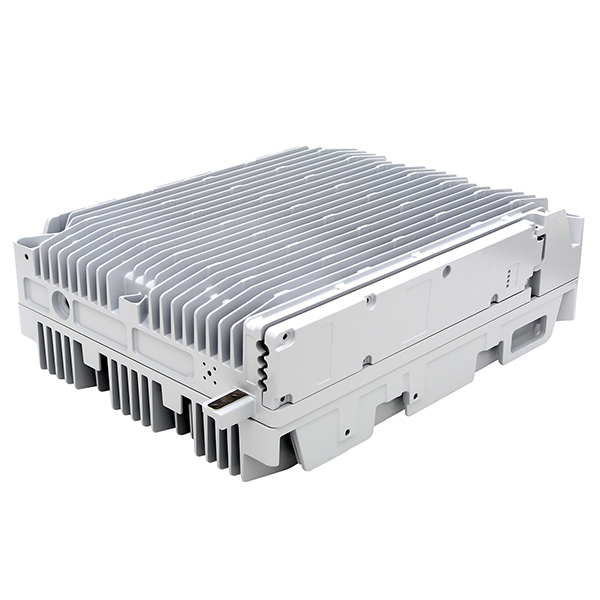

Communication Equipment Housing Die Casting Process Control

Control Focus:

ZH Precision ensures stable EMI shielding, efficient thermal dissipation, structural rigidity, and high cosmetic quality. We focus on maintaining uniform wall thickness, precise dimensional stability, and defect-free surfaces to guarantee signal integrity, assembly accuracy, and long-term reliability in demanding communication environments.

Process Technology:

We apply high-precision die casting with optimized alloy formulations for enhanced EMI performance. Real-time mold temperature control and refined gating design enable complete filling of thin-wall structures and heat-sink features. Vacuum-assisted casting reduces porosity, while mold-integrated surface preparation improves final finishing. Critical interfaces undergo precision CNC machining to achieve micron-level flatness and alignment, ensuring sealing performance and electromagnetic compatibility.

Aluminum Die-Casting Material

ZH Precision offers a wide range of aluminum die casting materials, including Aluminum ADC06, ADC12, A360, A380, A383, LM06, and HH334R. These alloys provide excellent castability, high strength, dimensional stability, and corrosion resistance. Contact us to select the aluminum material best suited for your project.

Aluminum Alloy

Aluminum die casting

Lightweight, corrosion-resistant, good strength-to-weight ratio. Used for complex, thin-walled car parts, airplane parts, and electronics.

- ADC06

- ADC12

- A360

- A380

- A383

- LM06

- HH334R

Trusted by Leading Global OEMs

We provide aluminum die casting services to world-renowned Original Equipment Manufacturers (OEMs), including FOXCONN, Airspan, ORACLE, JUNIPER, Alnan, and SAGERAN. Leveraging stable quality, reliable aluminum die casting capabilities, and responsive engineering support, we at ZH Precision are your trusted aluminum die casting manufacturer.

What is Aluminum Die Casting?

Aluminum die casting is a manufacturing process used to make metal parts by forcing molten aluminum into a mold under high pressure. Once the metal cools and solidifies, it takes the exact shape of the mold, creating parts with smooth surfaces and precise dimensions.

This process is perfect for producing large quantities of strong, lightweight parts—such as motor housings, heat sinks, and structural components. It is commonly used in the automotive, electronics, lighting, and industrial sectors.

Aluminum die casting offers many advantages, including excellent strength-to-weight ratio, good corrosion resistance, and the ability to create complex shapes in one process. At ZH Precision, we use high-quality alloys like ADC12 and A380 to ensure durability and consistent performance in every part we produce.

Applications of Aluminum Die Casting

ZH Precision’s aluminum die castings are widely used across industries for their strength, durability, and cost-effectiveness. Our precision casting process produces high-quality components suitable for demanding applications.

- Automotive Parts: Engine blocks, transmission cases, stators, forks, and heat sinks, engineered for high strength, lightweight performance, and precise tolerances.

- Aerospace Components: Fuselage frames, wing spars, and structural parts requiring a high strength-to-weight ratio and reliable dimensional accuracy.

- Industrial Machinery: Gears, pulleys, sprockets, pump covers, and brackets, crafted for durability and precise fit in complex assemblies.

- Electrical Components: Switchgear housings, transformer cases, and junction boxes, leveraging aluminum’s excellent conductivity and non-magnetic properties.

- Consumer Products: Decorative hardware, furniture, and architectural accents, combining aesthetic appeal with robust performance.

- Recreational Equipment: Boat hulls, snowmobile frames, and structural components, designed for reliability and precision under dynamic conditions.

Frequently Asked Questions About Aluminum Die Casting

Quick answers to common questions on material choice, design, and processes for parts like auto housings and heat sinks. Understand its applications fast.

Need more details? Contact our engineers.

A: Aluminum die casting offers an excellent strength-to-weight ratio, good thermal and electrical conductivity, high corrosion resistance, and the ability to produce complex, thin-walled parts with tight tolerances.

A:The most widely used alloys are ADC12 (A383) for excellent castability and corrosion resistance, and A380 for a balanced combination of strength, fluidity, and thermal properties.

A: Typical wall thickness ranges from 0.9mm to 1.5mm for most applications, with advanced processes capable of achieving walls as thin as 0.6mm for lightweight structural components.

A: HPDC is a process where molten aluminum is injected into a steel mold under very high pressure (400-1000+ bar). It is used for high-volume production of parts with excellent surface detail and dimensional consistency, such as automotive components and electronic housings.

A: For very low volumes (e.g., under 1,000 parts), the high initial cost of the permanent steel mold often makes die casting less economical than processes like CNC machining or 3D printing. However, for medium to high volumes, the low per-part cost makes it highly cost-effective.