Automation Industry

CNC prototyping and on-demand production for the automation industry, supporting the development of automation equipment, mechanical structures, and precision components with tight tolerances and reliable quality.

Verify Certifications On Demand:ISO 9001:2015 | IATF 16949:2016

Home » Automation

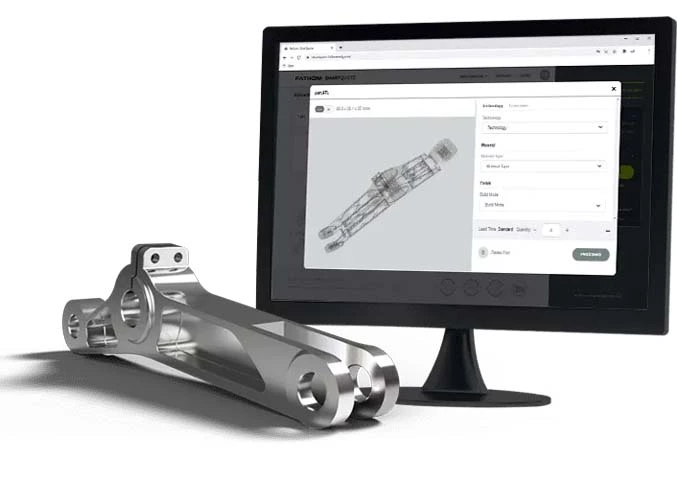

Why CNC Prototyping Matters for Automation Equipment Components

Automation equipment components must operate reliably under continuous loads, vibration, heat, and mechanical stress. Even small deviations in dimensions or material stability can affect motion accuracy and system performance. CNC prototyping allows engineers to validate designs, test fit and assembly, and ensure functionality before full-scale production. This process reduces costly design errors, accelerates development cycles, and guarantees high-quality, dependable components for motors, sensors, frames, and other critical parts used in automation machinery.

Why Choose Us for Automation Parts Manufacturing

We deliver high-precision automation components with consistent quality, advanced equipment, and engineering expertise. Our focus on manufacturability, repeatability, and long-term reliability ensures every part meets strict requirements and supports dependable system performance.

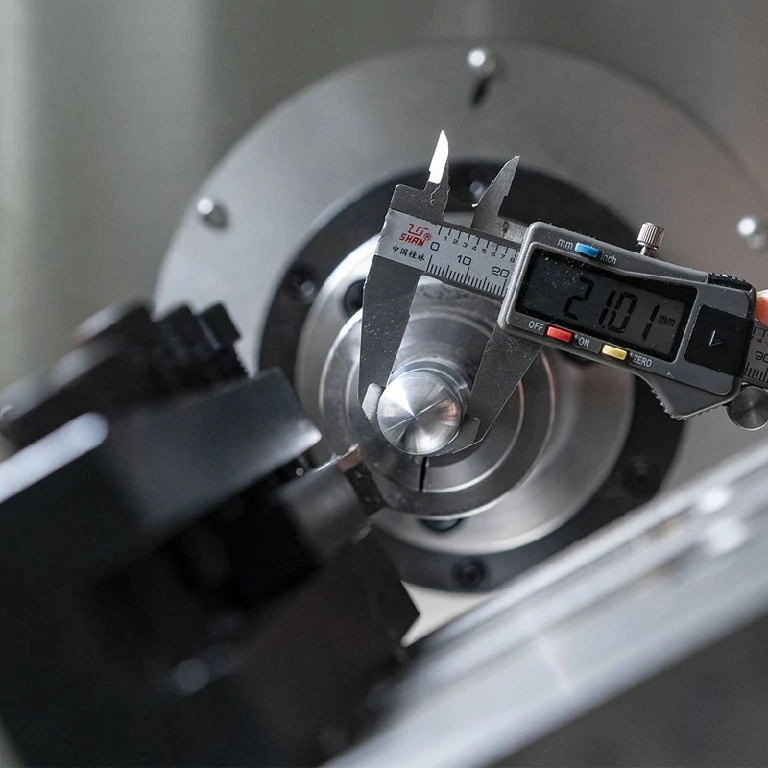

Quality Assurance

Every part is inspected with ZEISS CMM, and detailed reports are provided to guarantee precise geometry, consistent quality, and reliable performance.

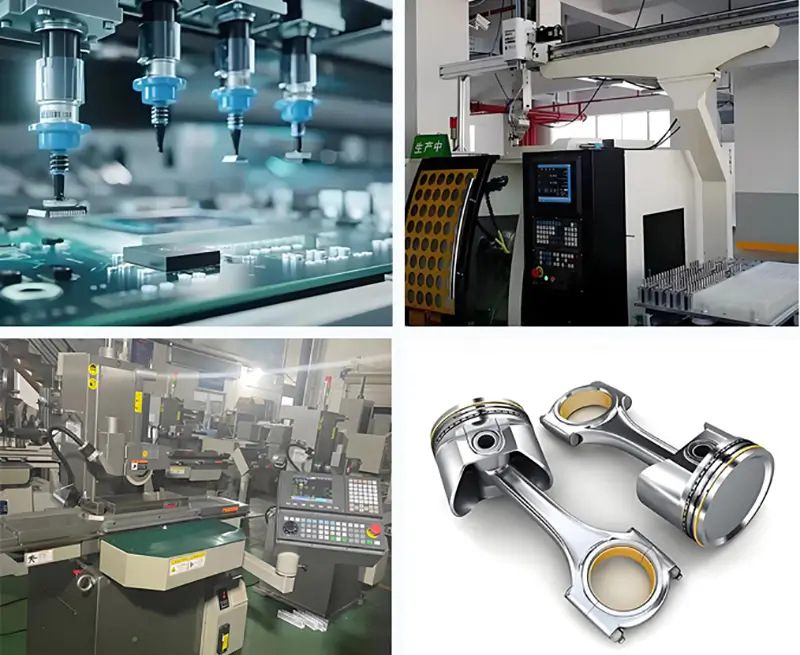

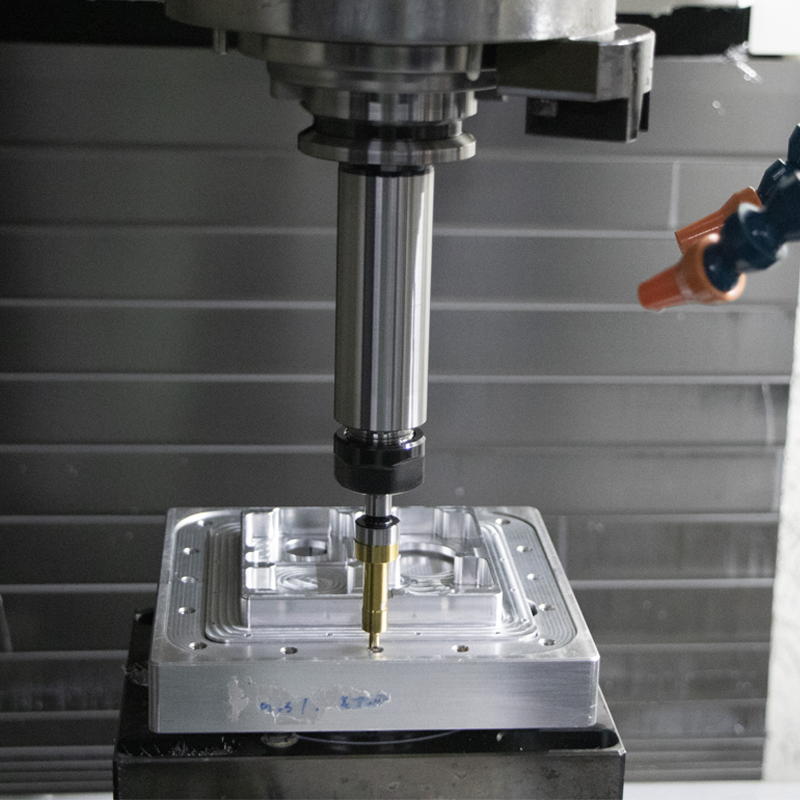

Advanced Equipment

We use GROB, GF Mikron, Jingdiao 5-axis, and Haas 4-axis machines, achieving tolerances as tight as ±0.0015 mm for precise, high-quality components.

Engineering Support

Our experienced engineers provide design feedback, DFM analysis, and project oversight to ensure every component is manufacturable, meets specifications, and performs reliably.

Automation Prototyping & New Product Development

Rapid prototyping plays a critical role in the automation industry. Before a system goes into production, engineers must verify mechanical fit, motion accuracy, structural strength, and assembly compatibility.

Rapid Prototyping

Bring your early-stage automation designs to life with prototypes produced strictly according to engineering drawings. This stage allows engineers to verify structural integrity, material suitability, and assembly fit before committing to production tooling. We provide CNC-based prototypes and flexible material options to support rapid design iterations and functional testing.

- Accurate prototypes reflecting final component geometry

- Structural and material validation under realistic conditions

- Rapid iteration to optimize mechanical design

Engineering Validation and Testing

Test functional prototypes to ensure they meet mechanical, structural, and motion requirements. EVT identifies potential weak points, assembly challenges, or material limitations early in the design process. We provide high-precision components and engineering feedback to support iterative improvements and reduce risk before design refinement.

- Verification of load-bearing structures and motion interfaces

- Assessment of material behavior under operational stresses

- Early detection of manufacturability and assembly issues

Design Validation and Testing

Refine and validate your design for assembly efficiency, tolerance alignment, and operational performance. At DVT, we produce prototypes using production-representative processes, allowing engineers to verify fit, function, and manufacturability. Surface finishes and material selections are tested to ensure reliability and readiness for pilot production.

- Optimize assembly workflow and component interactions

- Validate performance under realistic operating conditions

- Ensure manufacturability and production readiness

Production Validation and Testing

Confirm that your design can be manufactured consistently at scale. Pilot production runs at our facilities validate process control, repeatability, and final part quality. Feedback from this stage ensures efficient assembly and reliable production performance before full-scale manufacturing.

- Verify repeatability and quality of production processes

- Confirm assembly efficiency and dimensional consistency

- Identify and resolve remaining manufacturing challenges

Mass Production

Seamlessly transition from pilot testing to full-scale production. We leverage CNC machining, die casting, sheet metal fabrication, and aluminum extrusion to deliver high-precision automation components. Rigorous inspection and process control ensure every part meets structural, functional, and dimensional requirements, providing reliable supply for industrial automation applications.

- Consistent high-quality parts across large volumes

- Tight tolerances and reliable mechanical performance

- Scalable production with engineering support for ongoing improvement

Get a free DFM assessment

Our engineers can evaluate your design and recommend the most cost-effective solution — from CNC machining and die casting to sheet metal fabrication and aluminum extrusion.

Our Automation Parts Manufacturing Services

Automation components require different manufacturing technologies to meet precision, strength, and functional requirements. We offer a full range of processes for prototypes and production parts, ensuring reliability and manufacturability.

CNC Machining

CNC milling and turning produce motion components, brackets, robotic parts, and structural plates with tight tolerances and consistent surface quality.

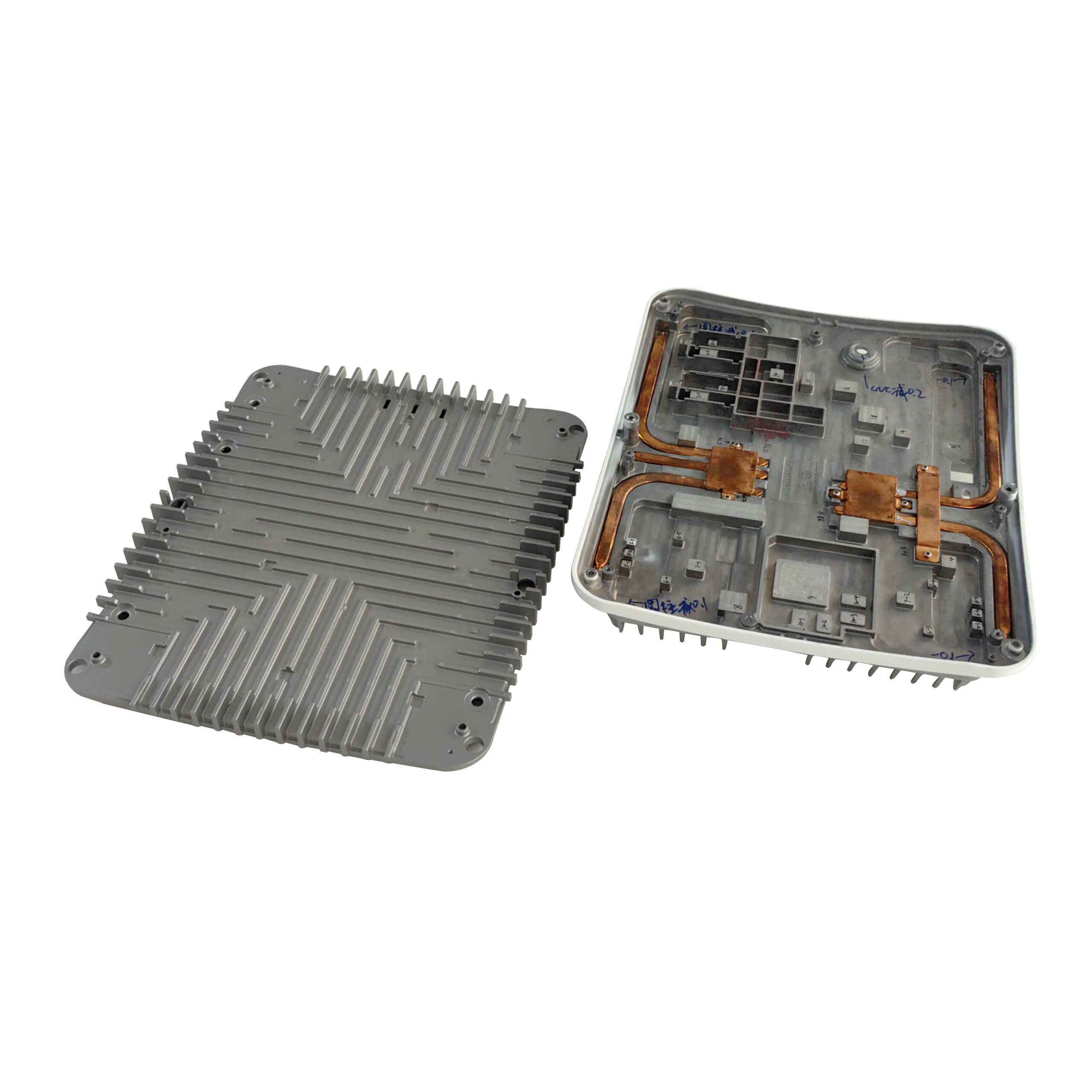

Die casting

Die casting is ideal for motor housings, control enclosures, and electronic covers, providing consistent dimensions and mechanical strength for high-volume parts.

Sheet Metal Fabrication

Sheet metal fabrication is used for control cabinets, machine covers, mounting frames, and structural panels, offering precision and rigidity.

Aluminum Extrusion

Aluminum extrusion creates lightweight, modular frames and support structures for conveyor systems, robotic cells, and automated lines.

Materials & Surface Finishes

Materials

We provide a variety of metals, including aluminum, steel, stainless steel, copper, and zinc alloys.

Surface Treatment

We offer superior surface finishes that enhance part durability and aesthetics for applications requiring smooth or textured surfaces.

Custom Parts for Automation Equipment

ZH Precision produces metal parts for automation equipment, including frames, brackets, mounting plates, motion components, and housings. These parts are installed in robotic systems, assembly lines, and industrial machinery. Every part is made to meet the required dimensions, strength, and surface quality for reliable operation in automated equipment.

- Gearbox Housing

- Motor Housing

- Servo Motor Bracket

- Stepper Motor Housing

- Robot Arm Base Plate

- Actuator Housing

- Transmission Coupling Hub

- Bearing Housing

- End Effector Body

- ensor Housing

- Linear Actuator Mount

- Machine Frame Bracket

- Pulley Hub

- Motor End Cap

- Gear Carrier

- Robotic Joint Housing

- Drive Shaft Housing

- Coupling Adapter

- Timing Pulley Body

- Aluminum Housing Panel

Trusted by Leading Global OEMs

ZH Precision is a manufacturing partner for global OEMs, including Foxconn, Airspan, Oracle, Juniper Networks, Alnan, and SAGERAN. With established capabilities, consistent quality, and responsive engineering support, we are a reliable supplier in the automation industry.

Extensive Industry Experience

Automation Industry FAQ

A. We produce a wide range of metal parts for automation equipment, including structural frames, brackets, shafts, housings, and precision mounts. These components are designed to withstand continuous operation, vibration, and high-load conditions.

A. CNC prototyping allows engineers to validate designs, ensure proper fit and function, and test performance before full-scale production. This reduces costly errors, accelerates development cycles, and guarantees reliable, durable components for automation machinery.

3. Yes, we provide fast prototypes based on your 2D/3D files through CNC machining, deburring and cleaning, secondary precision machining, surface finishing, and proper protection before shipping.

A:Yes, we support both low-volume prototypes and small-to-medium production runs. Our CNC capabilities ensure consistent quality and tight tolerances even for custom or limited-run parts.

A: Every part undergoes strict quality control, including dimensional inspection, material verification, and functional testing. Our focus on precision machining ensures parts meet the demanding standards of automation equipment and industrial applications.