Communications Industry

ZH Precision manufactures custom metal parts for communications equipment, including RF enclosures, antenna brackets, and structural housings used in 4G/5G and network systems.

- ISO 9001 Certified Manufacturing

- Transparent Quotes & DFM Feedback

- Complete Finishing, Joining & Assembly Services

- Industry-Experienced Engineering Support

Verify Certifications On Demand:ISO 9001:2015 | IATF 16949:2016

Home » communications

Why CNC Prototyping Matters in the Communications Industry

In the communications industry, parts often face issues like poor fit, signal interference, and durability problems. CNC prototyping helps solve these by allowing fast, accurate production of custom parts. Engineers can quickly create and test prototypes to identify and fix issues before mass production, saving time and cost. This helps ensure that parts are reliable, function well, and meet the design requirements. CNC prototyping speeds up the development process and reduces the risk of costly mistakes, which is crucial in the fast-changing communications market.

Why Telecom Communications Choose ZH Precision

At ZH Precision, we maintain clear and consistent communication throughout every project, keeping customers informed at each stage to ensure alignment, timely updates, and responsive support.

High Quality Parts

ZH Precision is certified to ISO 9001 and IATF 16949 standards, with quality management at the core of our manufacturing processes. We take a customer-focused approach to ensure consistent quality, reliable delivery, and project success.

Customer First

We take a customer-focused approach by understanding project requirements, maintaining clear communication, and providing responsive engineering and production support throughout the manufacturing process.

Engineering Support

Our engineering team leverages over 15 years of combined experience, providing DFM analysis with every machining and die casting quote, and assigning a dedicated project engineer to ensure smooth execution and risk mitigation.

From prototyping to production with our support

More than manufacturing. We support new product development from concept and prototyping through production, helping innovative teams reduce risk, shorten lead times, and launch products with confidence.

Rapid Prototyping

Turn your early-stage communications designs into functional prototypes with high precision. Our team creates enclosures, structural supports, and interface modules to help you test form, fit, and function quickly, enabling early design validation and faster decision-making.

- Fast proof of functionality

- Realistic prototype models

- Production-grade materials

Engineering Validation

Ensure your communications equipment components meet performance, reliability, and manufacturability requirements. We analyze materials, tolerances, and structural integrity to reduce risk, optimize design, and prepare your project for efficient production.

- 24/7 engineering support

- Design optimization

- Material selection

- Functional accuracy

Design Verification

Verify the performance, fit, and aesthetics of your communications equipment components before production. Our testing evaluates surface quality, structural strength, and usability, ensuring each part is ready for integration and meets industry standards.

- Surface finishing check

- Function and fit assessment

- Life-cycle testing

Production Validation

Test parts under production-grade conditions to validate manufacturability, tolerances, and assembly compatibility. Our team identifies adjustments early, ensuring a smooth transition from prototypes to larger-scale production with minimal risk.

- Production-ready adjustments

- Tight tolerance verification

- Manufacturing method validation

- Low-volume pilot runs

Mass Production

Seamlessly scale to full production of high-precision communications equipment components. We maintain strict quality standards, tight tolerances, and fast delivery, ensuring your products meet reliability, performance, and aesthetic requirements for market readiness.

- High-quality components

- Precision machining

- Post-processing operations

- Comprehensive quality inspection

Get a free DFM assessment

Our engineers can evaluate your design and recommend the most cost-effective solution — from CNC machining and die casting to sheet metal fabrication and aluminum extrusion.

Communications Manufacturing Services

We deliver integrated manufacturing services for communications equipment components, combining precision machining, die casting, finishing, and quality control into a streamlined production workflow. This approach reduces supply chain complexity while ensuring stable quality and dependable delivery for critical communication enclosures and structural parts.

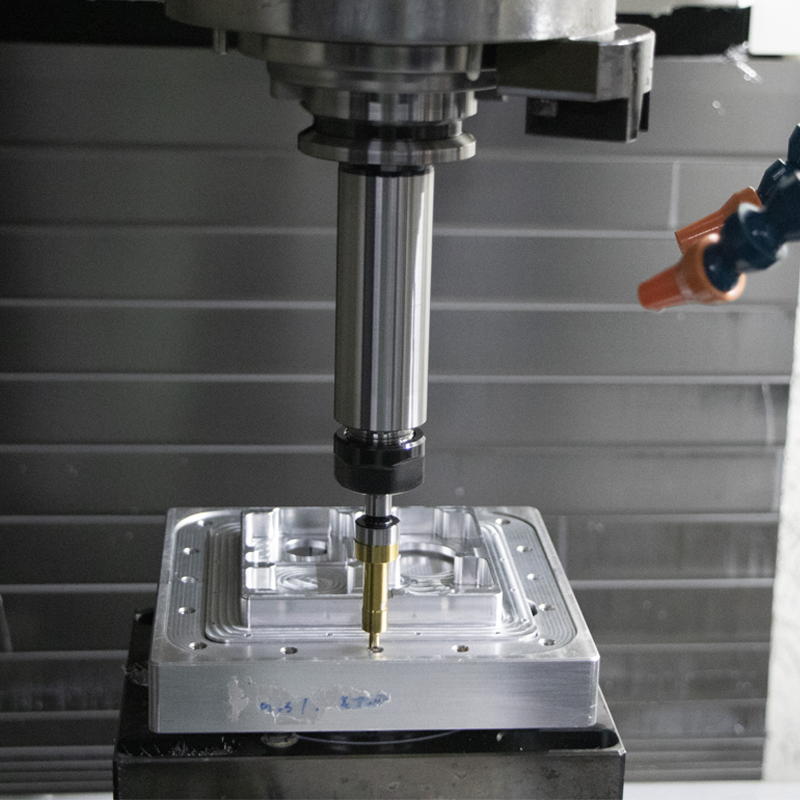

CNC Machining

Precision CNC machining for communication components with tight tolerances, complex features, and reliable dimensional consistency.

Die casting

Cost-effective die casting for aluminum communication housings, delivering stable dimensions and consistent surface quality at scale.

Sheet Metal Fabrication

Sheet metal fabrication for communication enclosures and brackets, offering structural reliability and flexible design options.

Aluminum Extrusion

Aluminum extrusion for communication profiles and structural parts, providing lightweight strength and uniform cross-sections.

Materials & Surface Finishes

Materials

We provide a wide range of materials, including metals, plastics, and composites.

Surface Treatment

We offer superior surface finishes that enhance part durability and aesthetics for applications requiring smooth or textured surfaces.

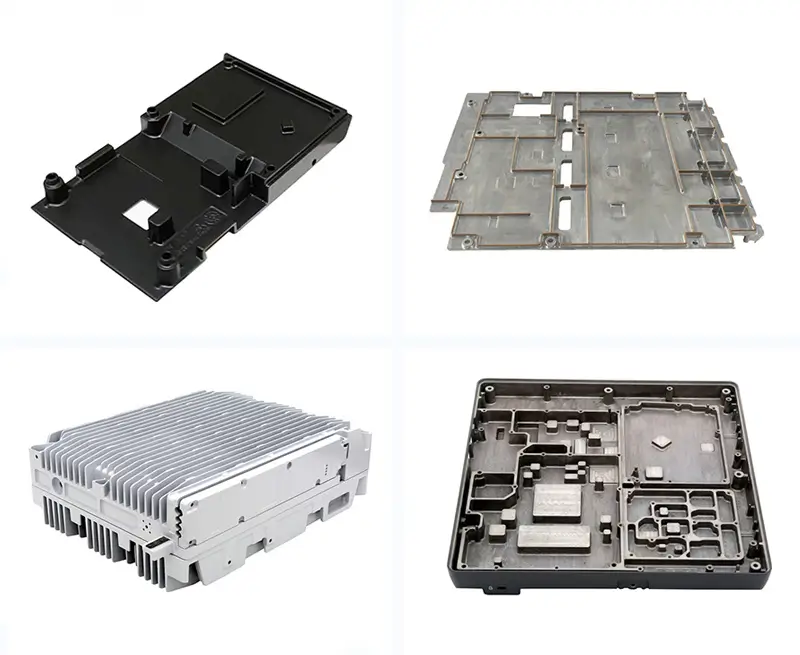

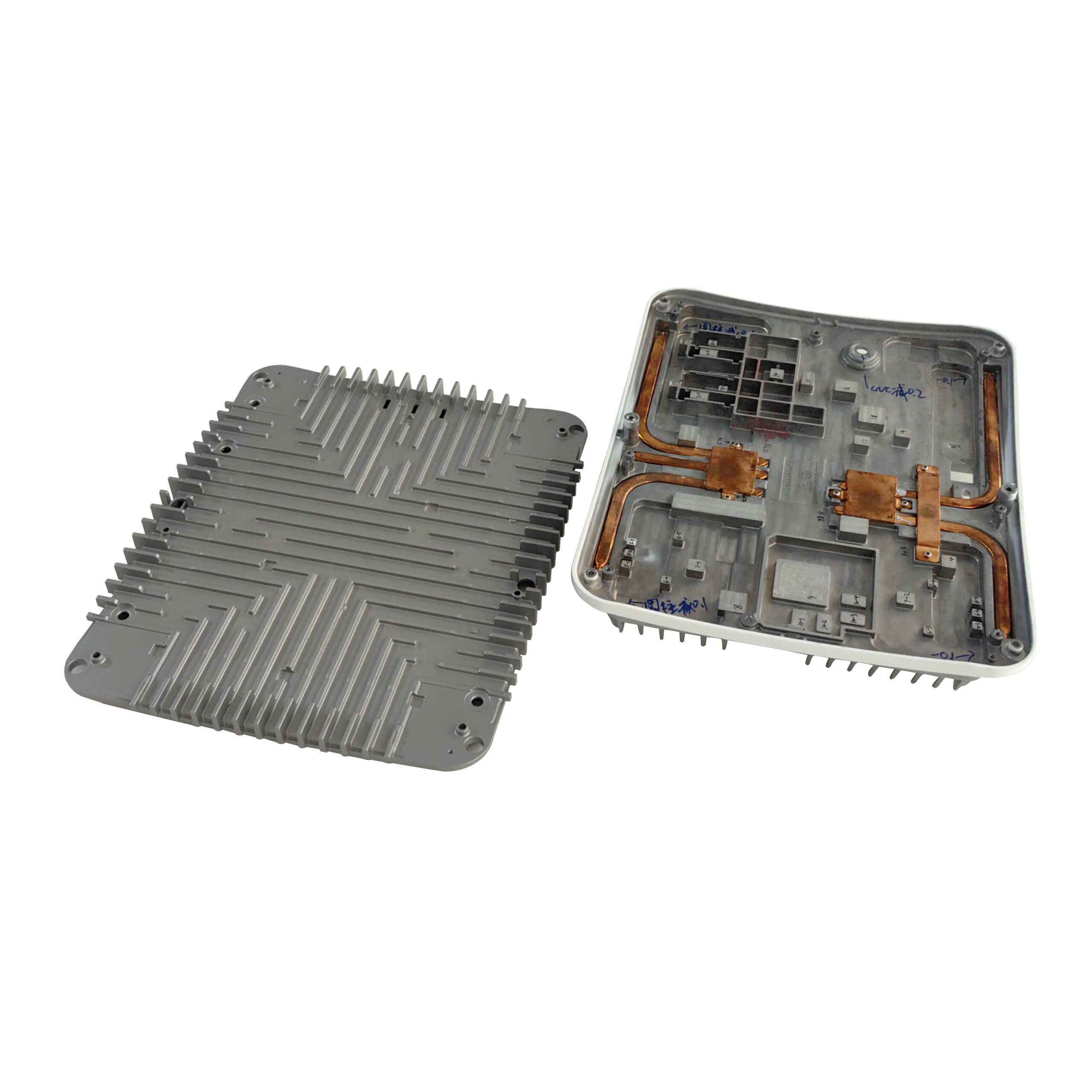

Which Communication Parts Can ZH Precision Produce?

ZH Precision manufactures a wide range of communication parts, including 4G and 5G radio unit housings, RF modules, antenna brackets, heat sinks, and enclosures. Our precision CNC machining and die casting capabilities ensure each component meets strict dimensional and functional requirements for reliable performance.

- 4G Radio Unit Housing

- 5G Radio Unit Housing

- RF Module Enclosure

- Antenna Support Bracket

- Fiber Optic Transceiver Case

- PCB Mounting Frame

- Signal Amplifier Enclosure

- EMI Shield Cover

- Satellite Communication Module Frame

- Small Cell Base Station Enclosure

- Waveguide Adapter

- Antenna Mounting Plate

- Heat Sink for Base Station Modules

- Router / Gateway Metal Chassis

- Microwave Filter Housing

- Telecom Junction Box

- Switchboard Mounting Plate

- Coaxial Connector Panel

- RF Filter Holder

- ONT Housing

Trusted by Leading Global OEMs

ZH Precision is a trusted manufacturing partner for some of the world’s most respected OEMs, including FOXCONN, Airspan, ORACLE, JUNIPER, Alnan, and SAGERAN. Our proven machining capability, stable quality, and responsive engineering support make us a reliable supplier for high-precision components used in communications and electronics applications.

Extensive Industry Experience

Communications Industry FAQ

Find answers to the most common questions about our telecom component manufacturing capabilities.

A. We produce RF housings, antenna brackets, filter cavities, heat sinks, enclosures, and other precision metal parts for 4G/5G communication equipment.

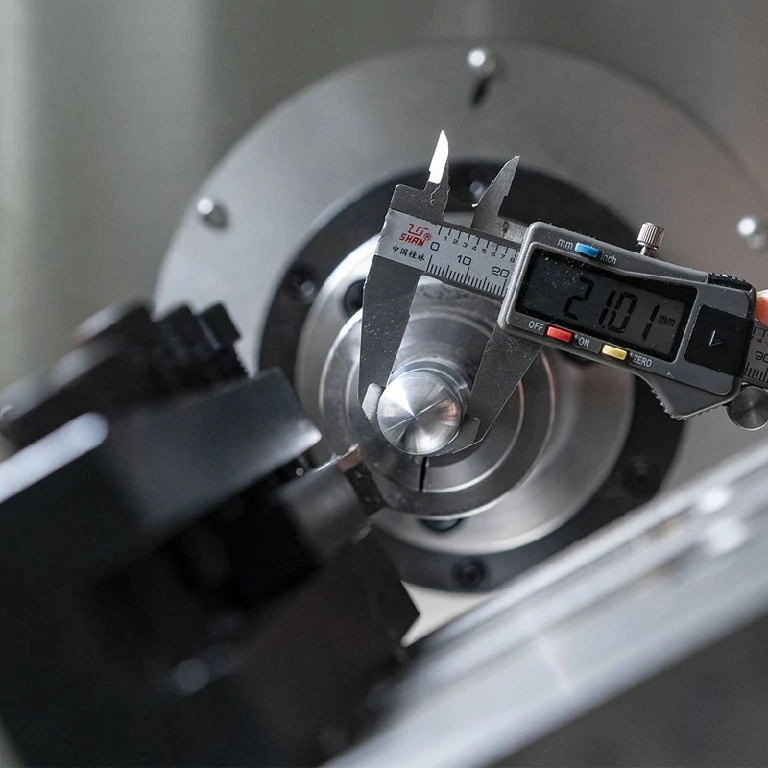

A. Our tolerance performance is tailored to the manufacturing process, and here are the specific achievable ranges:

- CNC machining: It can stably control the tolerance within ±0.003–0.008 mm. This precision is fully capable of meeting the production needs of key RF and communication parts, avoiding problems such as poor assembly or signal interference caused by size errors.

- Die casting: As a high-efficiency forming process, its tolerance is generally ±0.02–0.1 mm. It is mainly used to produce large structural parts of communication equipment, which can well balance production efficiency and the basic dimensional requirements of parts.

If you have special precision needs, we can combine the two processes to adjust the tolerance to the required level.

3. Yes, we provide fast prototypes based on your 2D/3D files through CNC machining, deburring and cleaning, secondary precision machining, surface finishing, and proper protection before shipping.

A:Yes. We offer free DFM checks to ensure proper heat dissipation, structural stability, and manufacturability for communication components.

A: Aluminum alloys (6061, 6063, A380, ADC12), brass, stainless steel, and other RF-friendly metals depending on weight, strength, and thermal requirements.