Consumer Goods Industry

Complete manufacturing solutions for consumer goods components, enabling fast prototyping and scalable production with consistent quality and reliable delivery.

- ISO 9001 Certified Manufacturing

- Transparent Quotes & DFM Feedback

- Complete Finishing, Joining & Assembly Services

- Industry-Experienced Engineering Support

Verify Certifications On Demand:ISO 9001:2015 | IATF 16949:2016

Home » Consumer Goods

Consumer Goods Parts Solutions

We provide precision components for the consumer electronics industry, covering everything from sleek external housings to complex internal parts. In a rapidly evolving market, our solutions help brands and OEMs accelerate product development while ensuring every component meets strict quality, functional, and aesthetic standards. Whether designing smartphones, wearables, audio devices, or other consumer electronics, we deliver dependable, cost-effective solutions tailored to your specific requirements, helping you bring innovative products to market efficiently and with confidence.

Why Choose Us for Consumer Goods Part Manufacturing

ZH Precision specializes in manufacturing parts and components for the commercial, consumer goods, instrumentation, digital, and home appliance industries. Using advanced processes and strict quality control, we deliver high-precision, consistently finished components with reliable long-term supply.

Precise Tolerances

We ensure every component meets tight dimensional and functional specifications, so your consumer products perform consistently and maintain design integrity, even in complex assemblies.

Rapid Response

From quotation to production, our engineering and operations teams ensure rapid feedback, flexible scheduling, and reliable delivery for urgent projects.

Engineering Support

With extensive experience in consumer product manufacturing, our engineers assist in design validation, material selection, and production planning to reduce risks and optimize performance.

We provide prototyping and production support

We support consumer goods programs across every stage of execution—from early builds to volume production. Our manufacturing workflows are designed to enable smooth transitions, minimize handoff risks, and ensure production readiness as designs move toward full-scale manufacturing.

Rapid Prototyping

Turn early-stage product concepts into functional prototypes for fast evaluation and iteration. This stage allows you to verify form, fit, and basic functionality while refining designs before moving forward. Flexible prototyping support helps reduce development risk and shorten design cycles.

- Low-volume prototyping and early production support

- Rapid iteration for design refinement

- Functional prototypes for concept evaluation

- Fast validation of product feasibility

Engineering Validation and Testing

Confirm that your product meets performance and functional requirements through engineering-focused validation. Prototypes at this stage closely represent the final design, enabling thorough evaluation and early identification of potential issues before design freeze.

- Functional verification of critical features

- Optimized material performance for design intent

- High-accuracy prototypes for engineering assessment

Design Validation and Testing

Validate product design, appearance, and user experience before production release. This phase focuses on confirming aesthetics, surface quality, and end-use functionality to ensure your product is market-ready and meets consumer expectations.

- Material and surface finish validation

- End-use functional evaluation

- Product life-cycle and reliability testing

Production Validation and Testing

Prepare your design for scalable production by validating manufacturability, consistency, and quality stability. Feedback from this stage helps finalize designs and ensures smooth transition into production with minimized risk.

- Verification of production-grade parts

- Consistent quality with tight dimensional control

- Low-volume production for final validation

Mass Production

Move confidently into full-scale production with stable quality control and reliable delivery. This stage focuses on producing end-use components that meet defined quality standards, performance requirements, and production timelines.

- Production-ready components for consumer products

- Consistent quality across production runs

- Comprehensive inspection and quality management

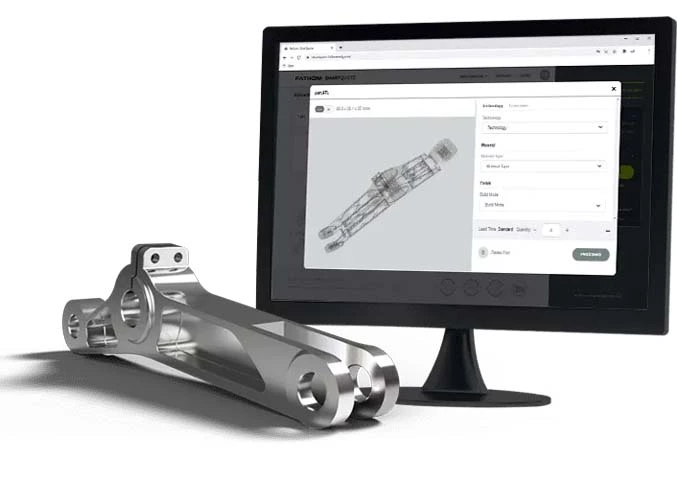

Get a free DFM assessment

Our engineers can evaluate your design and recommend the most cost-effective solution — from CNC machining and die casting to sheet metal fabrication and aluminum extrusion.

Consumer Goods Parts Manufacturing Services

ZH Precision operates advanced manufacturing facilities offering CNC machining, die casting, sheet metal fabrication, aluminum extrusion, and surface finishing. We provide customized solutions for consumer goods parts, ensuring precision, efficiency, and consistent quality from design support through production and assembly.

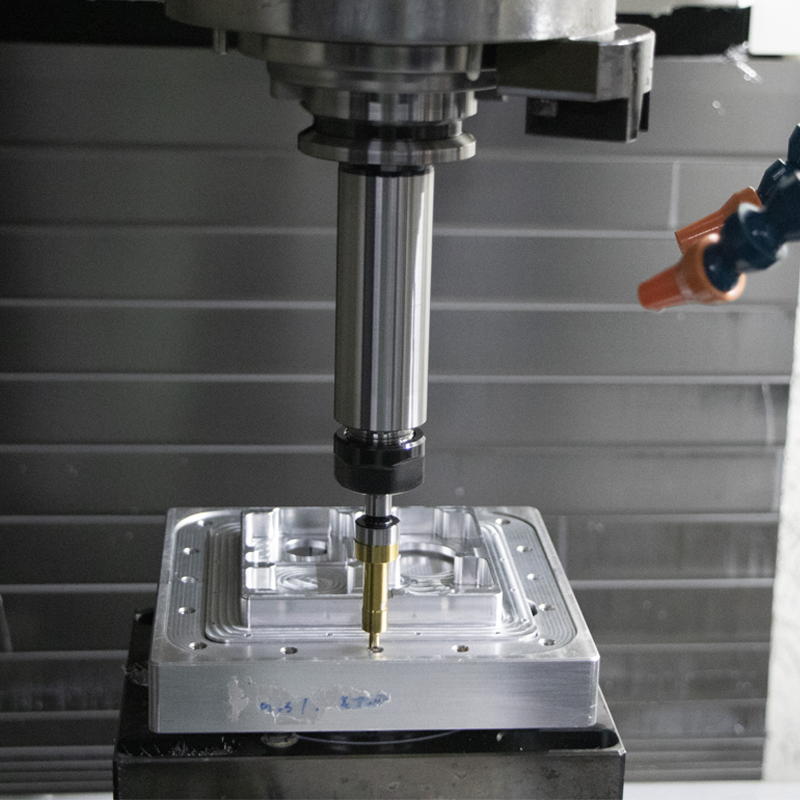

CNC Machining

3-axis, 4-axis, and 5-axis CNC machining for complex consumer goods parts with tight tolerances and consistent quality.

Die casting

We offer one-stop aluminum, zinc, and magnesium die casting services to meet your diverse manufacturing needs.

Sheet Metal Fabrication

Versatile sheet metal fabrication for housings, brackets, and enclosures, delivering precise bends, cuts, and assemblies.

Aluminum Extrusion

Custom aluminum extrusion for structural and aesthetic components, combined with secondary operations for finished, ready-to-use parts.

Materials & Surface Finishes

Materials

We provide a variety of metals, including aluminum, steel, stainless steel, copper, and zinc alloys.

Surface Treatment

We offer superior surface finishes that enhance part durability and aesthetics for applications requiring smooth or textured surfaces.

Applications in Consumer Goods

Discover our high-quality components for the consumer goods industry, combining aesthetic appeal, functional performance, and long-lasting durability. We provide parts for home appliances, electronics, personal devices, furniture, and lifestyle products, helping brands deliver reliable and durable products.

- Smart home device enclosures

- Wearable device metal cases

- Kitchen appliance metal housings

- Coffee machine components

- Vacuum cleaner frames and supports

- Hair dryer metal parts

- Electric toothbrush components

- Shaver and trimmer housings

- LED lighting fixtures and housings

- Smart thermostat metal frames

- Home security camera mounts

- Electric kettle metal parts

- Air purifier structural components

- Portable fan housings

- Personal care device metal parts

- Appliance brackets and supports

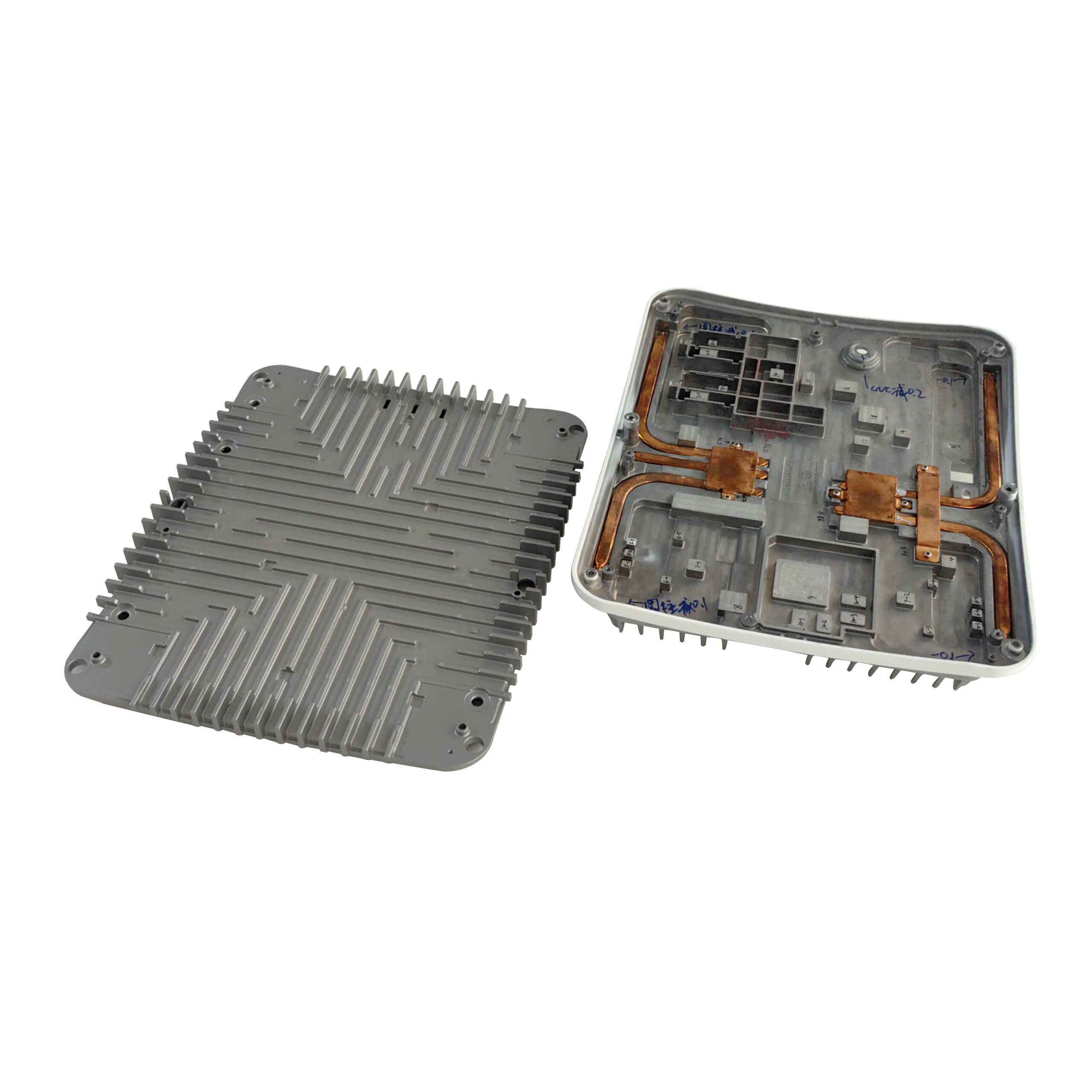

- Electronic device heat sinks

- Smart speaker enclosures

- Consumer electronics metal buttons

Trusted by Leading Global OEMs

ZH Precision is a trusted manufacturing partner for many leading global OEMs, including Foxconn, Airspan, Oracle, Juniper Networks, Alnan, and SAGERAN. With advanced manufacturing capabilities, consistent product reliability, and responsive engineering support, we are a dependable partner for the consumer goods industry.

Extensive Industry Experience

Consumer Goods Industry FAQ

A. We produce RF housings, antenna brackets, filter cavities, heat sinks, enclosures, and other precision metal parts for 4G/5G communication equipment.

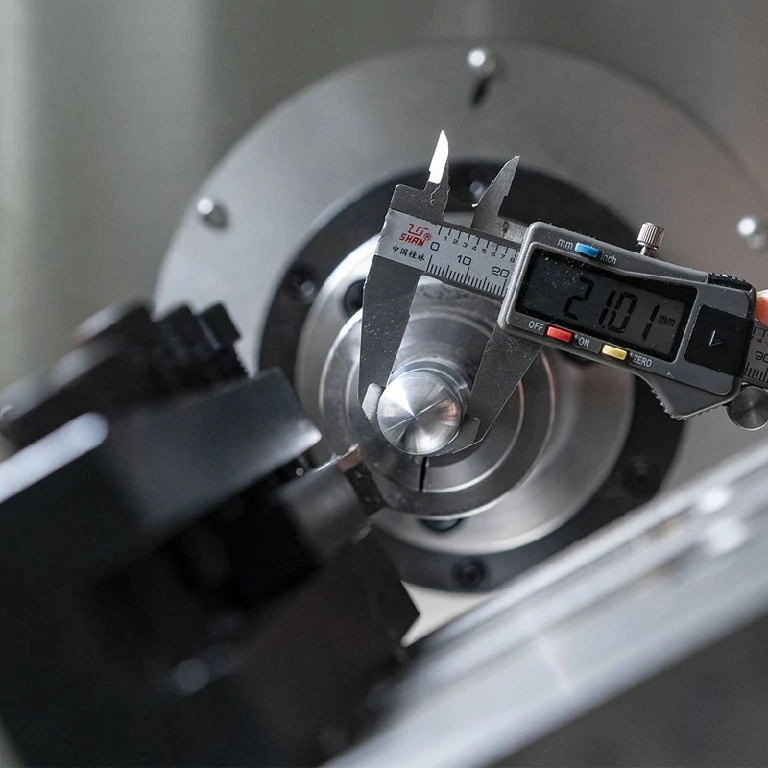

A. Our tolerance performance is tailored to the manufacturing process, and here are the specific achievable ranges:

- CNC machining: It can stably control the tolerance within ±0.003–0.008 mm. This precision is fully capable of meeting the production needs of key RF and communication parts, avoiding problems such as poor assembly or signal interference caused by size errors.

- Die casting: As a high-efficiency forming process, its tolerance is generally ±0.02–0.1 mm. It is mainly used to produce large structural parts of communication equipment, which can well balance production efficiency and the basic dimensional requirements of parts.

If you have special precision needs, we can combine the two processes to adjust the tolerance to the required level.

3. Yes, we provide fast prototypes based on your 2D/3D files through CNC machining, deburring and cleaning, secondary precision machining, surface finishing, and proper protection before shipping.

A:Yes. We offer free DFM checks to ensure proper heat dissipation, structural stability, and manufacturability for communication components.

A: Aluminum alloys (6061, 6063, A380, ADC12), brass, stainless steel, and other RF-friendly metals depending on weight, strength, and thermal requirements.