Custom Die Casting Services

We provide custom die casting services for complex metal components, ensuring high dimensional accuracy, structural integrity, and consistent quality. From engineering evaluation to stable mass production, our solutions deliver reliable performance across diverse applications, with a strong focus on manufacturability, process stability, and quality control for both functional and appearance-critical parts.

- ISO 9001:2015 Certified

- Samples as fast as 5-10 days

- Expert DFM & Engineering Support

- 100% Dimensional Inspection Guarantee

Verify Certifications On Demand:ISO 9001:2015 | IATF 16949:2016

Home » Die Casting

Get a Free DFM Quote

STP I SLDPRT I IPT I PRT I SAT FLES

All uploaded content is secure and confidential.

Engineering Support for Custom Die-Cast Parts

At ZH Precision, we provide end-to-end engineering support for custom die-cast components, ensuring each design is optimized for DFM, structural performance, and durability. Our engineers carefully evaluate wall thickness, draft angles, rib placement, tolerances, and thermal and mechanical stresses. Using advanced simulation tools alongside proven die casting methodologies, we identify potential issues early, recommend design improvements, and validate manufacturability. This process ensures that aluminum, zinc, and magnesium parts are produced with high precision, repeatability, and minimal defects.

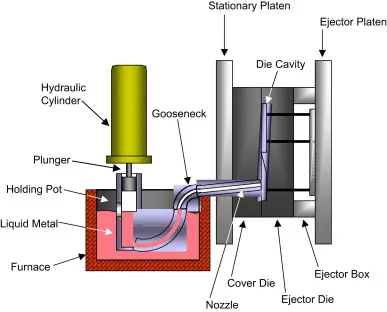

Hot Chamber Die Casting

Hot chamber die casting is a high-efficiency casting process primarily used for zinc and other low-melting-point alloys. In this process, the injection system is submerged in molten metal, allowing for rapid cycle times and excellent metal flow. This method enables the production of complex parts with smooth surface finishes, tight dimensional consistency, and high repeatability. Hot chamber die casting is well suited for high-volume manufacturing of housings, brackets, connectors, and other precision components where efficiency and consistent quality are critical.

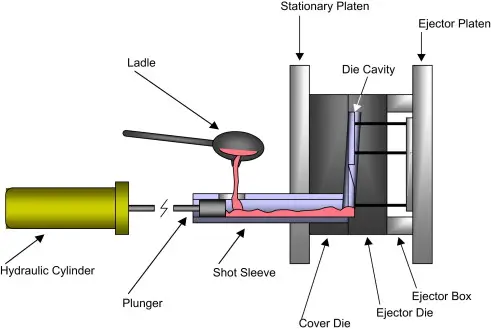

Cold Chamber Die Casting

Cold chamber die casting is commonly used for aluminum and magnesium alloys that require higher melting temperatures. Molten metal is transferred into the shot chamber for each cycle, allowing better control of metal injection and reduced thermal stress on the equipment. This process is suitable for structurally demanding parts with thicker walls and higher strength requirements, offering good dimensional accuracy and reliable performance in medium- to high-volume production.

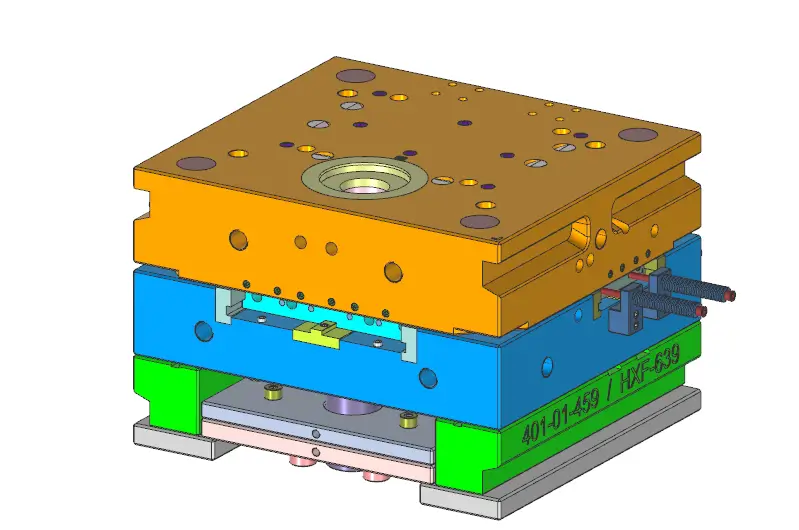

End-to-End Die Casting Manufacturing Services

Our die casting services cover the complete manufacturing lifecycle, allowing customers to manage projects efficiently with a single, reliable partner.

Mold Design & Manufacturing

Die Casting Production

Secondary Processing

CNC Precision Machining

Surface Treatment

100% Full Inspection

ZH Precision Die Casting Capabilities

| Feature | Description |

|---|---|

| Minimum Part Weight | 0.001 kg |

| Maximum Part Weight | 50 kg |

| Minimum Part Size | Ø17 mm × 4 mm |

| Maximum Part Size | 300 mm × 650 mm |

| Minimum Wall Thickness | 0.8 mm |

| Maximum Wall Thickness | 12.7 mm |

| Quality Control | ISO 9001 Certified |

| Maximum Die Life (Number of Cycles) | Magnesium / Aluminum: ~100,000 cycles, Zinc: ~1,000,000 cycles |

| Minimum Order Quantity | 1 piece |

| Standard Lead Time | 20–25 days. Specific timing varies based on mold type and product structure complexity. |

- Note: The data in the table is for reference only; the actual data will be determined based on the specific situation.

Available Die Casting Finishes

ZH Precision offers a variety of die casting finishes to match your parts’ functional, aesthetic, and durability needs. From enhanced corrosion resistance to polished surfaces or improved performance, we have the right option for your project. Explore all finishing options →

Standard (As-Cast)

Delivers a functional finish with smooth surfaces and minimal tool marks, ideal for non-cosmetic die casting applications.

Anodizing

Enhances corrosion resistance and surface hardness while adding color for improved durability and appearance.

Polishing

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

Sand Blasting

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

Tumbling

Tumbling smooths and polishes small parts by friction and abrasion in a barrel, offering a consistent but slightly textured finish.

Electropolish

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Electroplating

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

Die Casting Materials

Choosing the right die casting material plays a key role in part performance, cost control, and production consistency. ZH Precision works closely with customers to support material selection for aluminum, zinc, and magnesium die casting based on design requirements and production needs.

Contact us today to discuss your project, receive technical guidance, or request a fast quotation.

Aluminum Die Casting

Aluminum alloys provide a balanced combination of strength, low density, and thermal stability. They offer good corrosion resistance, stiffness, and dimensional consistency, making them suitable for components requiring structural reliability and heat dissipation performance.

- ADC06

- ADC12

- A360

- A380

- A383

- LM06

- HH334R

Zinc Die Casting

Zinc alloys feature excellent fluidity and castability, supporting thin walls and fine details. They deliver good mechanical strength, dimensional stability, and surface finish consistency, with minimal variation across production runs.

- Zinc Alloy 2

- Zamak 3

- Zamak 5

- Zamak 7

- ZA-8

- EZAC

- ZA-27

Magnesium Die Casting

Magnesium alloys have very low density and a high strength-to-weight ratio. They offer good rigidity, vibration damping properties, and dimensional accuracy while minimizing overall component weight.

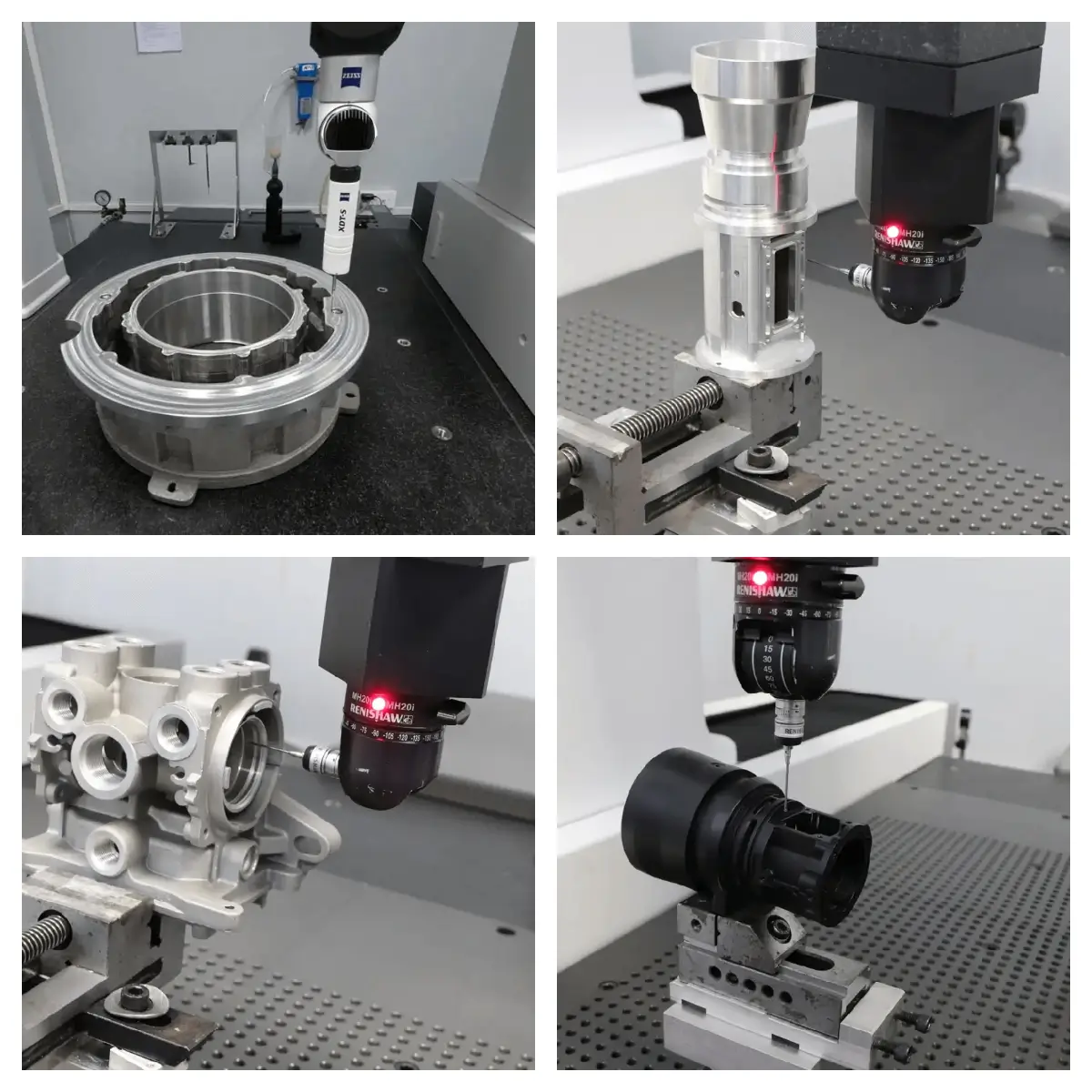

Die Casting Quality Control

ZH Precision strictly follows ISO 9001:2015 and IATF 16949:2016, applying rigorous quality control throughout the die casting process. From material verification and in-process monitoring to final inspection, every stage is carefully managed to ensure consistent performance, dimensional accuracy, and reliable delivery of aluminum, zinc, and magnesium components.

1. Material Verification

All incoming materials undergo strict verification to ensure they meet project specifications and industry standards.

2. Precision Machining Oversight

Our experienced machining team maintains tight tolerances and consistent adherence to design specifications throughout the production process.

3. Final Inspection & Verification

Every finished part undergoes 100% dimensional, surface, and functional inspection, ensuring full compliance with customer requirements and ready-to-ship quality.

Trusted by Leading Global OEMs

We provide aluminum die casting services to world-renowned Original Equipment Manufacturers (OEMs), including FOXCONN, Airspan, ORACLE, JUNIPER, Alnan, and SAGERAN. Leveraging stable quality, reliable aluminum die casting capabilities, and responsive engineering support, we at ZH Precision are your trusted aluminum die casting manufacturer.

Frequently Asked Questions

Quick answers to common questions on material choice, design, and processes for parts like auto housings and heat sinks. Understand its applications fast.

Need more details? Contact our engineers.

A: Die casting commonly uses aluminum, zinc, and magnesium alloys. Aluminum offers a good strength-to-weight ratio and corrosion resistance, zinc provides excellent dimensional stability and surface finish, and magnesium is lightweight for applications requiring reduced mass. Choosing the right material depends on part function, mechanical requirements, and production volume.

A: Hot chamber die casting is typically used for low-melting-point metals like zinc and magnesium, offering faster production rates. Cold chamber die casting is suitable for higher-melting-point metals such as aluminum, providing better control for larger parts. The choice depends on alloy selection, part size, and production requirements.

A: Die casting parts can achieve tight dimensional tolerances, typically within ±0.1–0.5 mm depending on size, material, and design complexity. Thin walls, deep cavities, and complex geometries may require careful design and process control to maintain accuracy. Tolerance capability can be further optimized using DFM principles and simulation tools.

A: Typical defects include porosity, warping, surface blemishes, and cold shuts. Prevention requires proper die design, optimal gating and venting, accurate temperature control, and careful alloy selection. Using simulation and in-process inspection helps identify issues early, ensuring consistent part quality.

A: Minimum order quantity can be as low as 1–10 pieces for prototyping, while mass production depends on tooling and part size. Standard lead time ranges from 2–4 weeks for prototypes and 3–6 weeks for production runs, depending on mold complexity, alloy, and finishing requirements.