Custom Magnesium Die Casting Services

Magnesium die casting produces lightweight, precise, and complex parts with excellent thin-wall capability. Its natural damping and EMI-shielding properties make it ideal for both prototypes and high-volume production.

Verify Certifications On Demand:ISO 9001:2015 | IATF 16949:2016

Home » Magnesium Die Casting

Get a Free DFM Quote

STP I SLDPRT I IPT I PRT I SAT FLES

All uploaded content is secure and confidential.

Magnesium Die Cast Parts Engineering Support

From concept to production, our expert team ensures your magnesium die-cast parts are precise, lightweight, and durable. Leveraging advanced CAE simulations, mold flow analysis, and CAD/CAM integration, we optimize every stage — minimizing defects, speeding up production, and reducing costs. Partner with us for reliable, high-performance magnesium components tailored to your exact requirements.

Advanced zinc die-casting equipment

We operate advanced hot- and cold-chamber die casting machines ranging from 88 to 2000 tons, enabling us to produce everything from small precision components to large structural parts. Automated process controls ensure stable casting performance, high production efficiency, and excellent surface finishes for all zinc die casting projects.

One-Stop Magnesium Die Casting Services

We provide a complete one-stop magnesium die casting solution, from mold design and manufacturing, die casting, CNC precision machining, to surface treatment. Leveraging in-house production and strict process control, we ensure every magnesium component delivers consistent dimensions and reliable lightweight performance, enabling efficient, stable, and high-quality batch production.

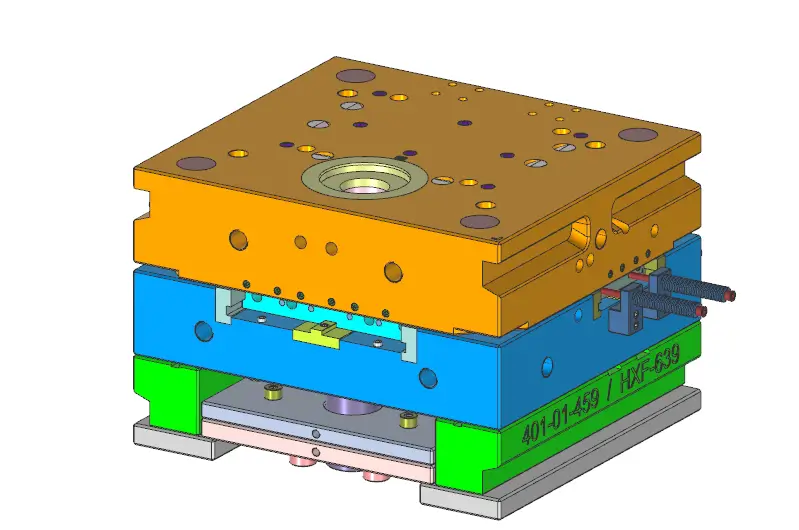

Mold Design & Manufacturing

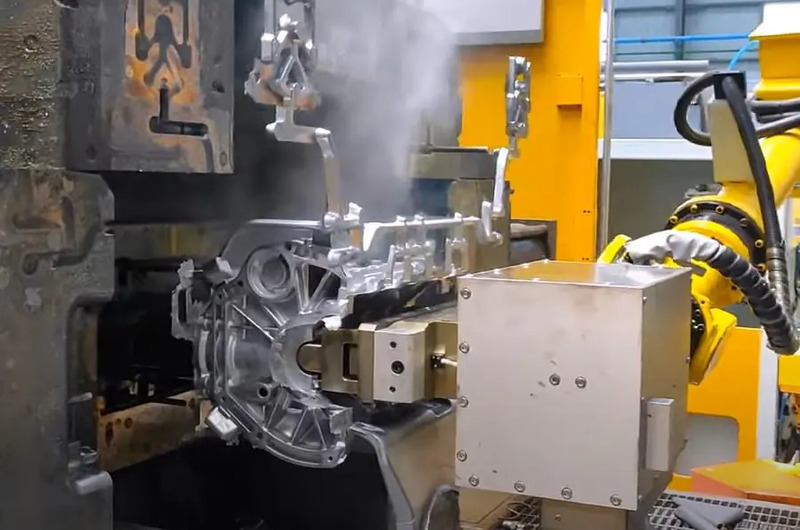

Die Casting Production

Secondary Processing

CNC Precision Machining

Surface Treatment

100% Full Inspection

Magnesium Thin-Wall Structural Casting with High Vacuum

Control Focus:

We precisely control melt quality, high vacuum levels, and intensification pressure to eliminate internal defects. This ensures pressure integrity, allows for T6 heat treatment, and meets strict strength-to-weight and EMI shielding standards for aerospace and high-end electronics.

Process Technology:

Using closed-chamber vacuum technology (cavity pressure <50 mbar), we achieve clean filling of thin walls (down to 1.0mm). A multi-stage injection profile ensures laminar flow, followed by immediate high-pressure intensification (>800 bar) and pulsed mold cooling. This yields dense, fine-grained components with superior mechanical properties and stability.

Quality Control of Die-Cast Parts

ZH Precision ensures every die-cast part meets strict quality standards through advanced process monitoring, certified systems, and precision testing.

Certified Quality System

Process Monitoring

Inspection & Testing

Composition and Applications of Different Magnesium Alloy

| Alloy | Composition | Applications |

|---|---|---|

| AZ91D | Mg, 9% Al, 1% Zn | Automotive parts, electronics, general casting |

| AM60B | Mg, 6% Al, 0.5% Mn | Automotive crash components, structural parts |

| AM50 | Mg, 5% Al, 0.5% Mn | Automotive safety parts, thin-walled castings |

| AE44 | Mg, 4% Al, 4% Rare Earth | Engine parts, high-temp applications |

| ZM21 | Mg, 2% Zn, 1% Mn | Aerospace parts, corrosion-resistant components |

| AZ63 | Mg, 6% Al, 3% Zn | General casting, automotive parts |

| ZE41 | Mg, 4% Zn, 1% Rare Earth | Aerospace, racing, helicopter gearboxes |

| AS41A | Mg, 4% Al, 1% Si | Engine parts, transmission cases |

| AX31 | Mg, 3% Al, 1% Ca | Aerospace, automotive, creep-resistant parts |

| MRI 153M | Mg, 5% Al, 3% Ca | High-temp engine parts, powertrain components |

Why Choose Magnesium Alloy?

Magnesium die casting offers an excellent balance of strength, precision, and lightweight performance. As one of the lightest structural metals, magnesium alloys allow for complex, thin-walled parts with high dimensional accuracy and outstanding surface quality. They provide excellent heat dissipation, electrical conductivity, and vibration damping—ideal for automotive, electronics, and aerospace applications. Fully recyclable and cost-efficient, magnesium die casting helps manufacturers reduce weight, improve performance, and achieve sustainable production goals.

What is magnesium die casting?

Magnesium die casting is a precision manufacturing process used to produce high-quality parts from magnesium alloys. In this process, molten magnesium is injected into a steel mold under high pressure, forming complex shapes with excellent dimensional accuracy and surface finish.

The process begins by melting the selected magnesium alloy in a controlled furnace. The molten metal is then forced into the mold cavity, where it rapidly cools and solidifies. This high-pressure casting method enables the creation of intricate geometries and thin-walled components that are lightweight yet strong, making magnesium die casting ideal for automotive, aerospace, electronics, and industrial applications.

Applications of Magnesium Die Casting

Magnesium die casting combines lightweight properties with high strength-to-weight ratio, excellent damping capacity, and good EMI shielding. ZH Precision delivers precision magnesium die-cast solutions for a wide range of industries and applications:

- Automotive: Steering wheel frames, seat brackets, battery housing components.

- Aerospace & Defense: Avionics housings, drone frames, equipment enclosures.

- 3C Electronics: Laptop unibodies, camera bodies, high-end device housings.

- Industrial & Medical: Robotic components, portable medical device frames.

- Prototyping & Low-Volume Production: Rapid iteration and bridge-to-production services.

Magnesium Die Casting FAQ

ZH Precision offers precision magnesium die casting for lightweight, strong, and complex parts. This FAQ answers common questions about materials, processes, tolerances, and finishes, helping you understand our capabilities.

A: Magnesium die casting is a process where molten magnesium alloy is injected into a steel mold under high pressure, producing lightweight, strong, and precise metal parts suitable for complex shapes.

A: Magnesium parts are extremely lightweight, have excellent strength-to-weight ratio, good corrosion resistance, high thermal and electrical conductivity, and can achieve tight tolerances and fine surface finishes.

A: Magnesium die-cast components are widely used in automotive, aerospace, electronics, consumer products, and industrial machinery due to their lightweight and durable properties.

A: Yes. Post-casting processes such as CNC machining, polishing, plating, painting, and coating can be applied to meet both functional and aesthetic requirements.

A: Our engineering team can help select the best alloy based on operating temperature, mechanical strength requirements, and environmental conditions to ensure optimal performance and durability.