Medical Device Industry

Accelerating innovation and simplifying sourcing for medical and surgical components, from rapid prototypes to scalable production with precise tolerances and reliable quality.

- ISO 9001 Certified Manufacturing

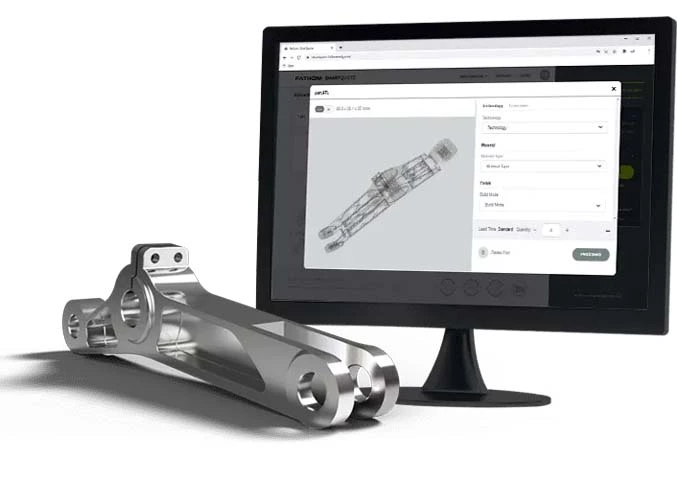

- Instant Quoting & DFM Feedback

- Complete Finishing, Joining & Assembly Services

- Industry-Experienced Engineering Support

Verify Certifications On Demand:ISO 9001:2015 | IATF 16949:2016

Home » Medical Devices

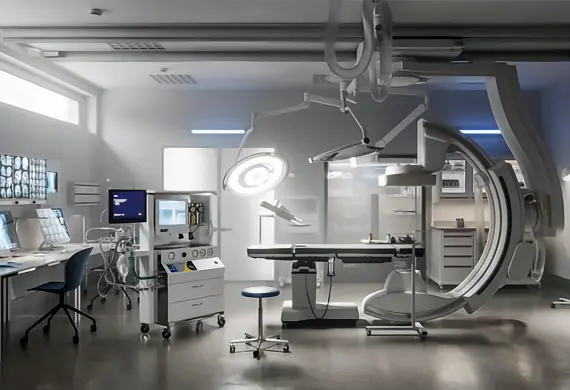

Medical Device Manufacturing Challenges

Medical devices require extremely high levels of precision and reliability, as even minor deviations can impact performance and patient safety. Components must consistently meet strict dimensional and material standards to ensure durability, accuracy, and safe operation in surgical instruments, implants, and diagnostic equipment.

Manufacturers must maintain these rigorous standards throughout the entire production process. This ensures that every medical device is dependable, safe, and capable of performing at the highest level, meeting the stringent requirements of the healthcare industry.

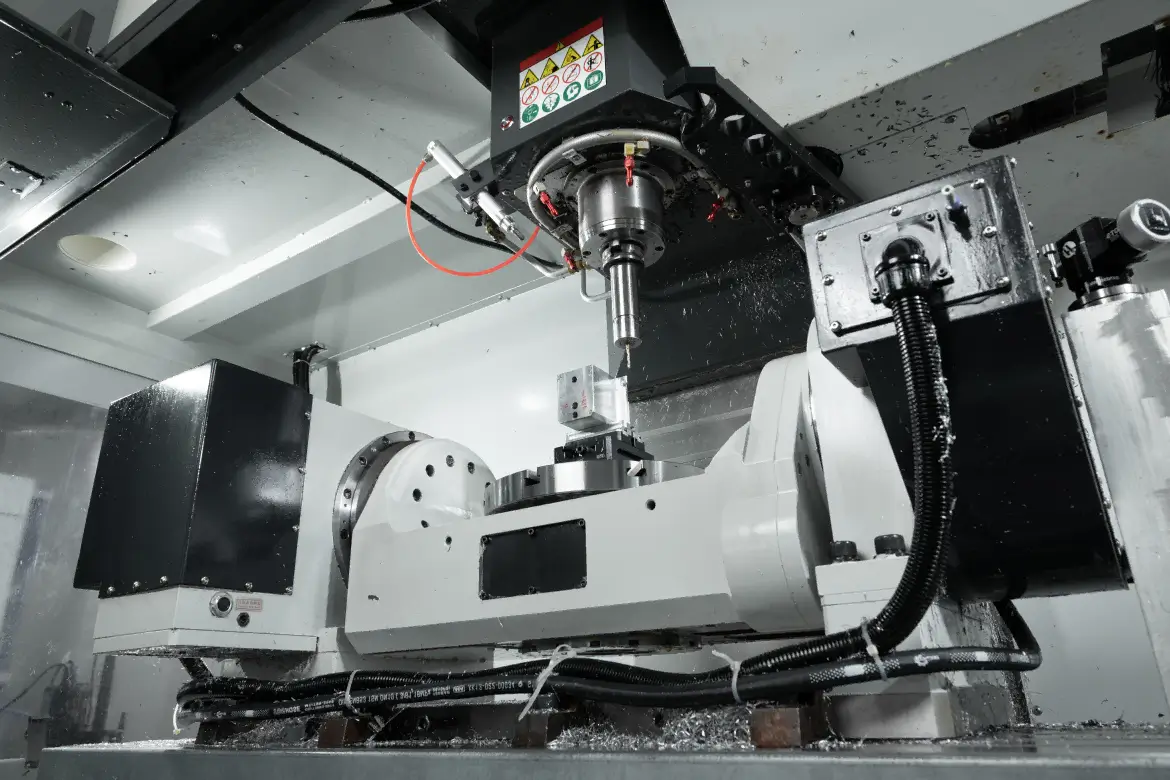

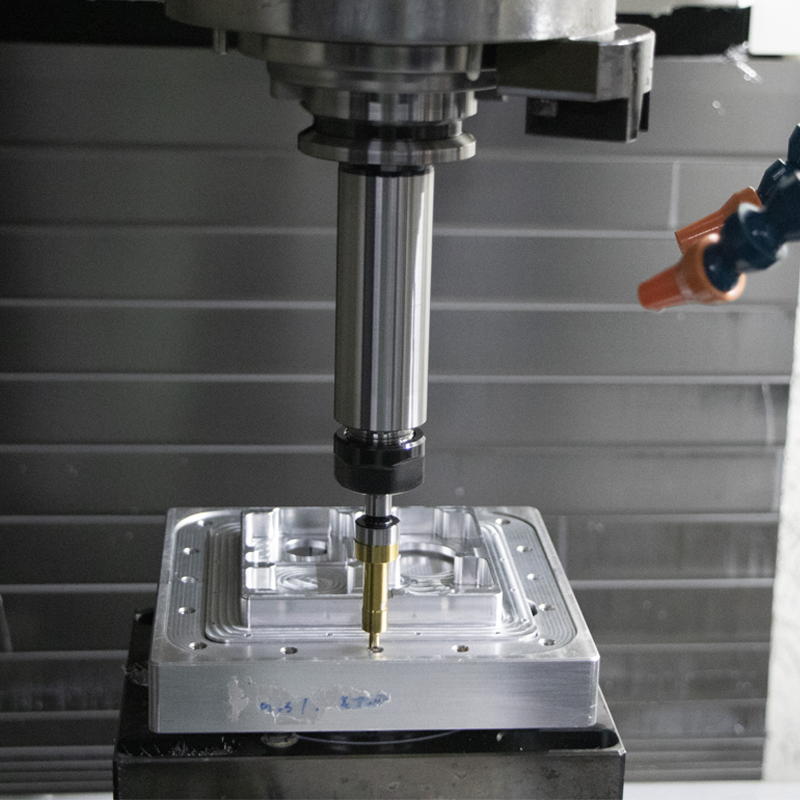

5-Axis CNC Machining for Medical Device Parts

leveraging 5-axis cnc technology allows us to machine multiple surfaces and complex angles in a single setup. this capability is crucial for medical components with freeform surfaces, eliminating the need for repositioning and significantly minimizing accumulated dimensional errors. this high-efficiency process guarantees superior surface finish and dimensional accuracy, making it the ideal solution for critical components like custom orthopedic implants and complex instrument housings.

Why Medical Device Components Choose ZH Precision

With over 15 years of manufacturing experience, ZH Precision delivers reliable production for medical device projects of all sizes. We specialize in complex parts, offer flexible volumes, and provide fast, dependable lead times to ensure every project meets cost, quality, and delivery requirements.

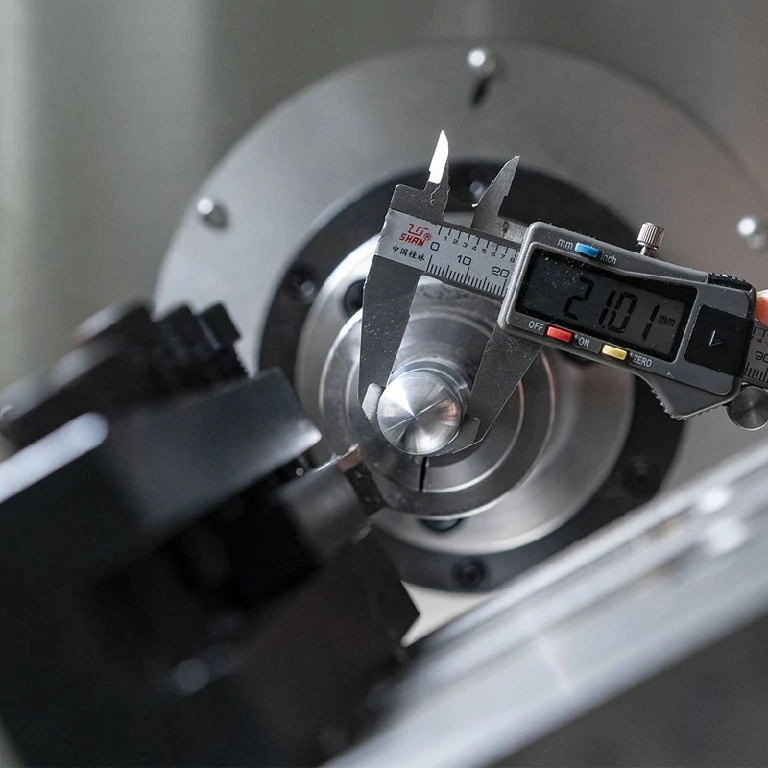

High Precision

We maintain tight tolerances and consistent accuracy, ensuring every component meets design specifications and delivers reliable performance.

Customer First

We work closely with customers to understand requirements, provide clear communication, and ensure projects are executed smoothly and reliably.

Engineering Support

Our experienced engineers provide DFM feedback with every quote, identifying risks early and optimizing designs for efficient, dependable manufacturing.

Prototyping Process for Medical Device Parts

our experienced engineers and machinists specialize in supporting the r&d phase. we quickly handle complex prototypes and low-volume orders, ensuring fast design validation and manufacturing feasibility.

Rapid Prototyping

Bring your initial designs to life with high-quality prototypes crafted from production-grade materials. Each prototype allows you to explore your component’s functionality, test different materials, and refine your design before moving into full production. Our team works closely with your design files to ensure every detail meets your specifications, giving you confidence in your concept.

- Quickly validate functionality and design

- Prototypes closely resemble the final product

- Use of production-grade materials to reduce design-to-production gaps

- Early detection of design or material issues to save time and cost

Engineering Validation and Testing

Test your functional prototypes under realistic conditions to uncover and resolve potential design or material challenges. This stage ensures that your components perform reliably and allows you to make targeted improvements before finalizing the design.

- Optimize design and material choices for dependable performance

- Reduce engineering iterations and accelerate development

- Ensure prototypes reflect the behavior of the final device

Design Validation and Testing

Evaluate your prototypes for performance, usability, and appearance. Gather actionable feedback to enhance functionality, improve durability, and refine the overall design. This stage helps you make informed adjustments that strengthen your product before production.

- Improve surface finish, ergonomics, and visual appeal

- Assess both functional and aesthetic aspects of components

- Receive insights to refine prototypes for optimal performance

Production Validation and Testing

Prepare your design for production using manufacturing-grade processes. Test and refine components to verify manufacturability, optimize assembly, and ensure consistent quality across batches. This stage helps you identify final adjustments that improve efficiency and performance.

- Implement production-ready design improvements

- Produce precision parts with tight tolerances

- Verify manufacturing methods to minimize risk

- Enable small-volume production for early testing

Mass Production

Move seamlessly from testing to full-scale production, ensuring every component meets your quality standards. Maintain consistent performance and durability across large volumes while optimizing efficiency and workflow.

- Deliver high-quality, production-ready components consistently

- Maintain tight tolerances and advanced post-processing standards

- Implement comprehensive quality inspection

- Scale production efficiently while preserving reliability

Get a free DFM assessment

Our engineers can evaluate your design and recommend the most cost-effective solution — from CNC machining and die casting to sheet metal fabrication and aluminum extrusion.

Our Medical Device Manufacturing Services

We embrace challenging medical components that many would shy away from, and our skilled team is adept at designing and overcoming any part-specific challenges to ensure reliable results.

CNC Machining

Precision CNC milling and turning for medical device components, producing reliable parts with tight tolerances and smooth surfaces.

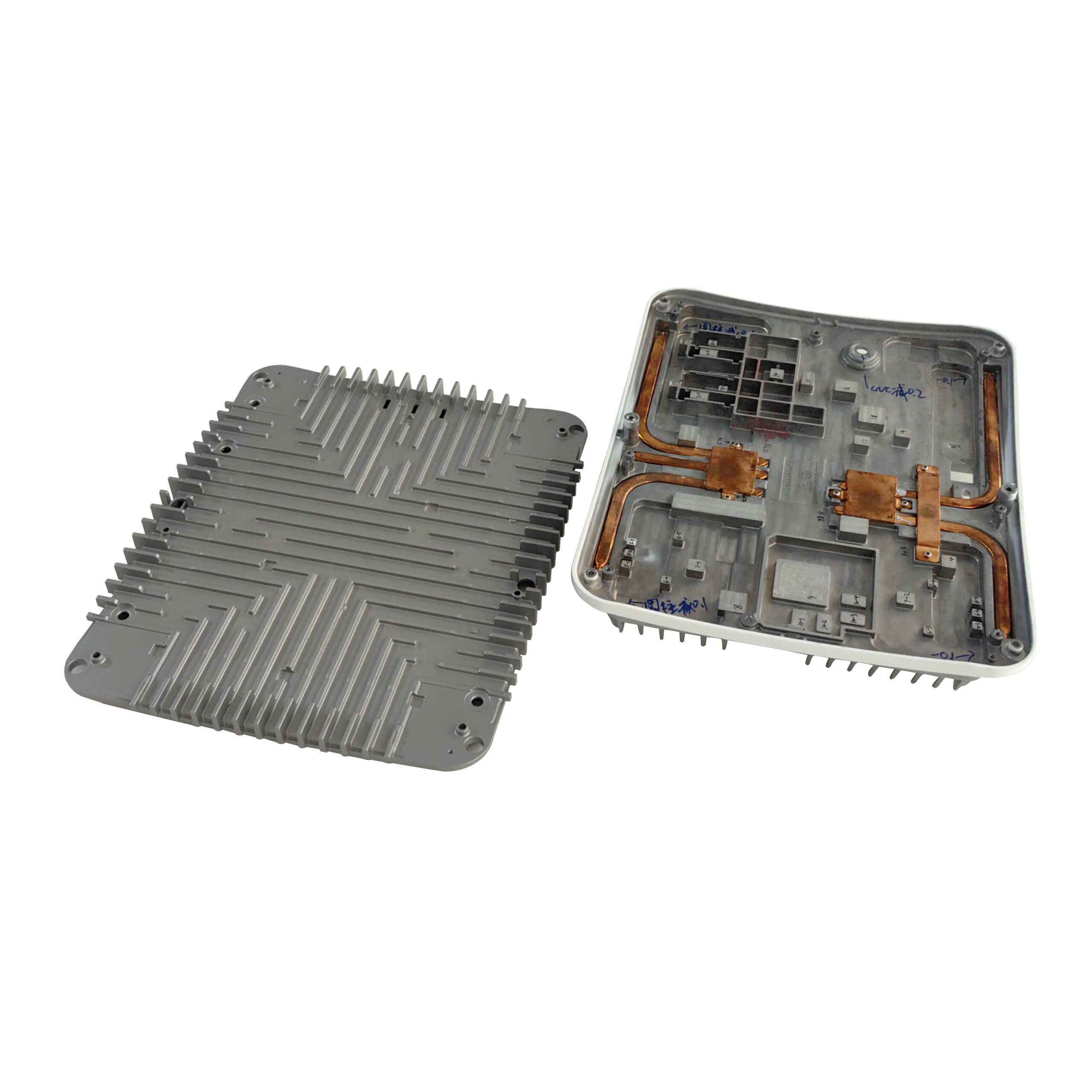

Die casting

One-stop die casting services for aluminum, zinc, and magnesium components, delivering durable and reliable parts for medical devices.

Sheet Metal Fabrication

Laser cutting, bending, welding, and assembly of durable sheet metal components with precise dimensions.

Aluminum Extrusion

Aluminum extrusion produces lightweight, durable components with precise, consistent shapes for a wide range of applications.

Materials & Surface Finishes

Materials

We provide a variety of metals, including aluminum, steel, stainless steel, copper, and zinc alloys.

Surface Treatment

We offer superior surface finishes that enhance part durability and aesthetics for applications requiring smooth or textured surfaces.

Applications in Medical Device

We provide precision components for medical devices, designed to meet strict standards for accuracy, cleanliness, and reliability. Our parts are used in surgical instruments, diagnostic equipment, prosthetics, and other critical applications, ensuring safe and consistent performance.

- Surgical Instrument Components

- Orthopedic Implant Parts

- Dental Device Components

- Endoscopic Tool Parts

- Diagnostic Equipment Housings

- Medical Pump Shafts

- Precision Gear Components

- Prosthetic Joint Components

- Catheter Device Components

- Surgical Fixture Parts

- Medical Device Casings

- Imaging Equipment Housings

- Infusion Pump Enclosures

- Portable fan housings

- Sterilization Equipment Components

- Medical Cart Frames

- Electronic Medical Device Chassis

- Defibrillator Enclosures

- Hospital Bed Mechanisms

- Laboratory Equipment Panels

Trusted by Leading Global OEMs

ZH Precision is a trusted manufacturing partner for some of the world’s most respected OEMs, including FOXCONN, Airspan, ORACLE, JUNIPER, Alnan, and SAGERAN. Our proven machining capability, stable quality, and responsive engineering support make us a reliable supplier for high-precision components used in communications and electronics applications.

Extensive Industry Experience

Communications Industry FAQ

Find answers to the most common questions about our telecom component manufacturing capabilities.

A. We produce RF housings, antenna brackets, filter cavities, heat sinks, enclosures, and other precision metal parts for 4G/5G communication equipment.

A. Our tolerance performance is tailored to the manufacturing process, and here are the specific achievable ranges:

- CNC machining: It can stably control the tolerance within ±0.003–0.008 mm. This precision is fully capable of meeting the production needs of key RF and communication parts, avoiding problems such as poor assembly or signal interference caused by size errors.

- Die casting: As a high-efficiency forming process, its tolerance is generally ±0.02–0.1 mm. It is mainly used to produce large structural parts of communication equipment, which can well balance production efficiency and the basic dimensional requirements of parts.

If you have special precision needs, we can combine the two processes to adjust the tolerance to the required level.

3. Yes, we provide fast prototypes based on your 2D/3D files through CNC machining, deburring and cleaning, secondary precision machining, surface finishing, and proper protection before shipping.

A:Yes. We offer free DFM checks to ensure proper heat dissipation, structural stability, and manufacturability for communication components.

A: Aluminum alloys (6061, 6063, A380, ADC12), brass, stainless steel, and other RF-friendly metals depending on weight, strength, and thermal requirements.