Custom Sheet Metal Fabrication Services

Every project requires a tailored approach. We provide end-to-end sheet metal fabrication services, transforming your requirements into precise, durable metal components. From rapid prototypes to full-scale production, our integrated processes and advanced equipment ensure each part is delivered on time and fully aligned with your design specifications.

- Flexible Low-Volume Production

- ±0.005mm Tight Tolerance

- Expert Engineering Support

Verify Certifications On Demand:ISO 9001:2015 | IATF 16949:2016

Home » Sheet Metal Fabrication

Get a Free DFM Quote

STP I SLDPRT I IPT I PRT I SAT FLES

All uploaded content is secure and confidential.

What is Sheet Metal Fabrication?

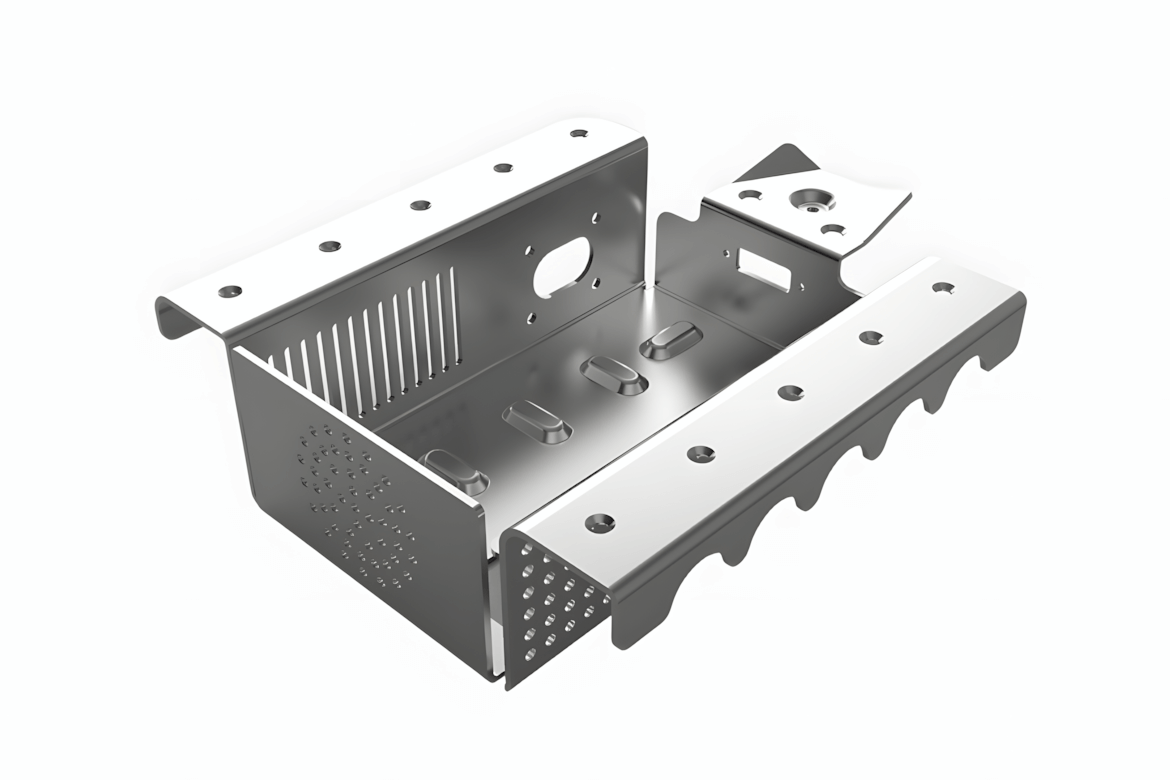

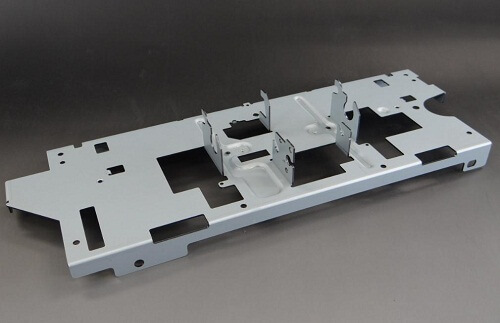

Sheet metal fabrication is the process of transforming flat sheets of metal into custom components and structures through cutting, bending, punching, welding, and assembling. It allows the creation of precise and durable parts for a wide range of industries, including automotive, electronics, industrial equipment, and construction. This process is valued for its flexibility, efficiency, and ability to produce both simple and complex shapes with high accuracy.

Advantages of Sheet Metal Fabrication

We provide flexible, efficient sheet metal fabrication from prototypes to small and large-scale production. Our capabilities include cutting, bending, stamping, and welding, enabling fast design validation and iterative development. With advanced machinery, diverse material options, and custom finishes, we deliver precise parts while optimizing cost and lead time, helping you respond quickly to market demands.

Our Sheet Metal Fabrication Capabilities

We provide precision sheet metal fabrication services, covering laser cutting, bending, welding, and assembly. Our advanced equipment and experienced team ensure high-quality, custom components for both prototyping and high-volume production.

Laser Cutting

It offers high precision and efficiency, ideal for complex, high-quality designs while minimizing waste. It rapidly cuts various metals, delivering clean, burr-free edges for superior results.

- Sharp, accurate cuts.

- Quick, enhances productivity.

- Works well with various materials.

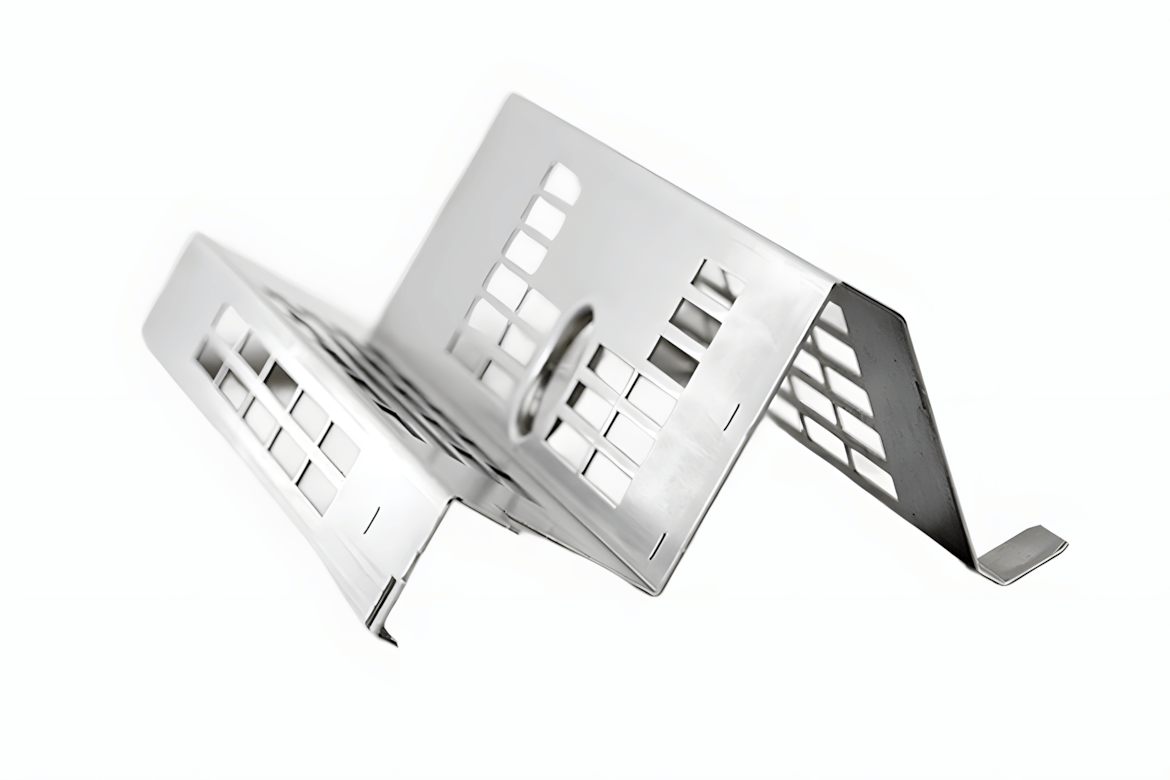

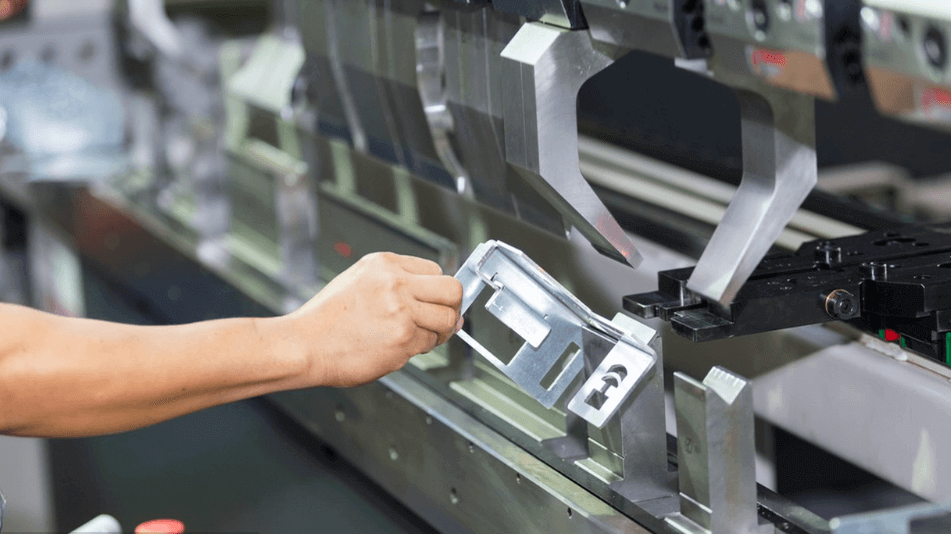

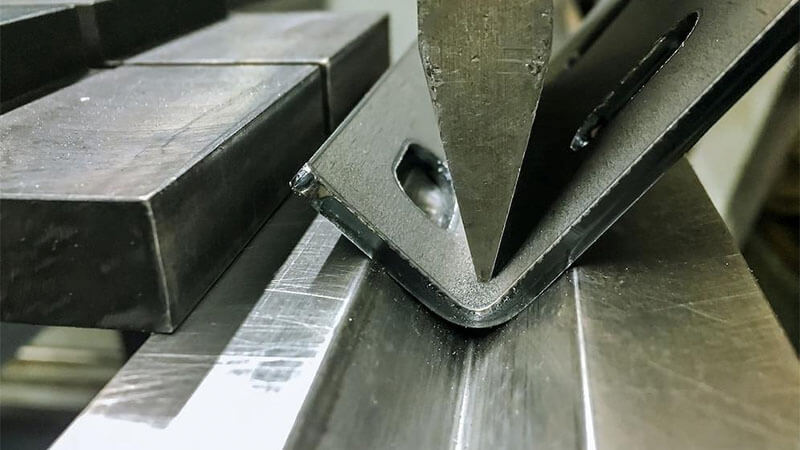

Bending

Bending applies force to thin metal sheets to shape them into various shapes, like U-shape, V-shape, or channel shape. The metal’s thickness may vary.

- Ensures consistent angles.

- Fast setup and execution.

- Compatible with various materials.

Welding

Welding is a process used to securely join two or more metal pieces utilizing heat, pressure, or both to form a strong joint.

- Create robust, long-lasting joints.

- Fast and cost-effective.

- Suitable for a range of materials.

Punching

Punching is a cost-effective method for creating holes or shapes in sheet metal. This process is ideal for high-volume production.

- Minimizes labor and material costs.

- Precise, clean results

- Ideal for large-scale production.

Riveting

Riveting is a semi-permanent joining method. It involves using rivets to assemble complex structures where welding is unsuitable.

- Durable, reliable connections.

- Prevents thermal distortion.

- Faster and much more cost-effective than welding.

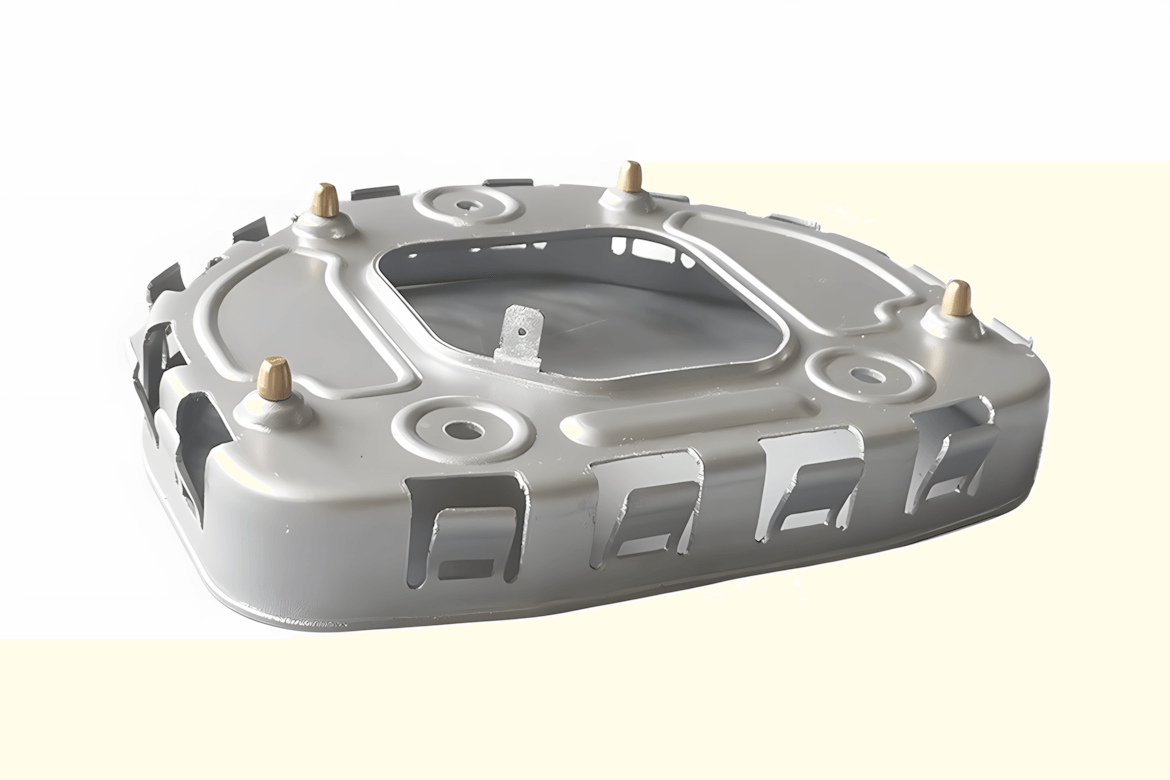

Stamping

Stamping uses dies and presses to shape flat metal sheets into unique forms. It is commonly used in automotive industries for complex geometries.

- Swift, extensive manufacturing.

- Consistent parts each time.

- Handles complex shapes effortlessly.

Our metal sheet processing capabilities

We maintain strict tolerance control for all sheet metal fabrication projects. Our in-house facilities produce parts with consistent dimensional accuracy, ensuring proper fit and assembly. Standard tolerances vary depending on material thickness, feature size, and process type. If you have any questions, please feel free to contact us. We are dedicated to serving you!

| Standard | Description |

|---|---|

| General Tolerances | Metals: ISO 2768-c |

| Cutting Feature | ± 0.00787" (0.2 mm) |

| Bend Angle | ± 1.0° |

| Bend to Edge | ± 0.010" (0.254 mm) |

| Bend to Hole | ± 0.2 mm |

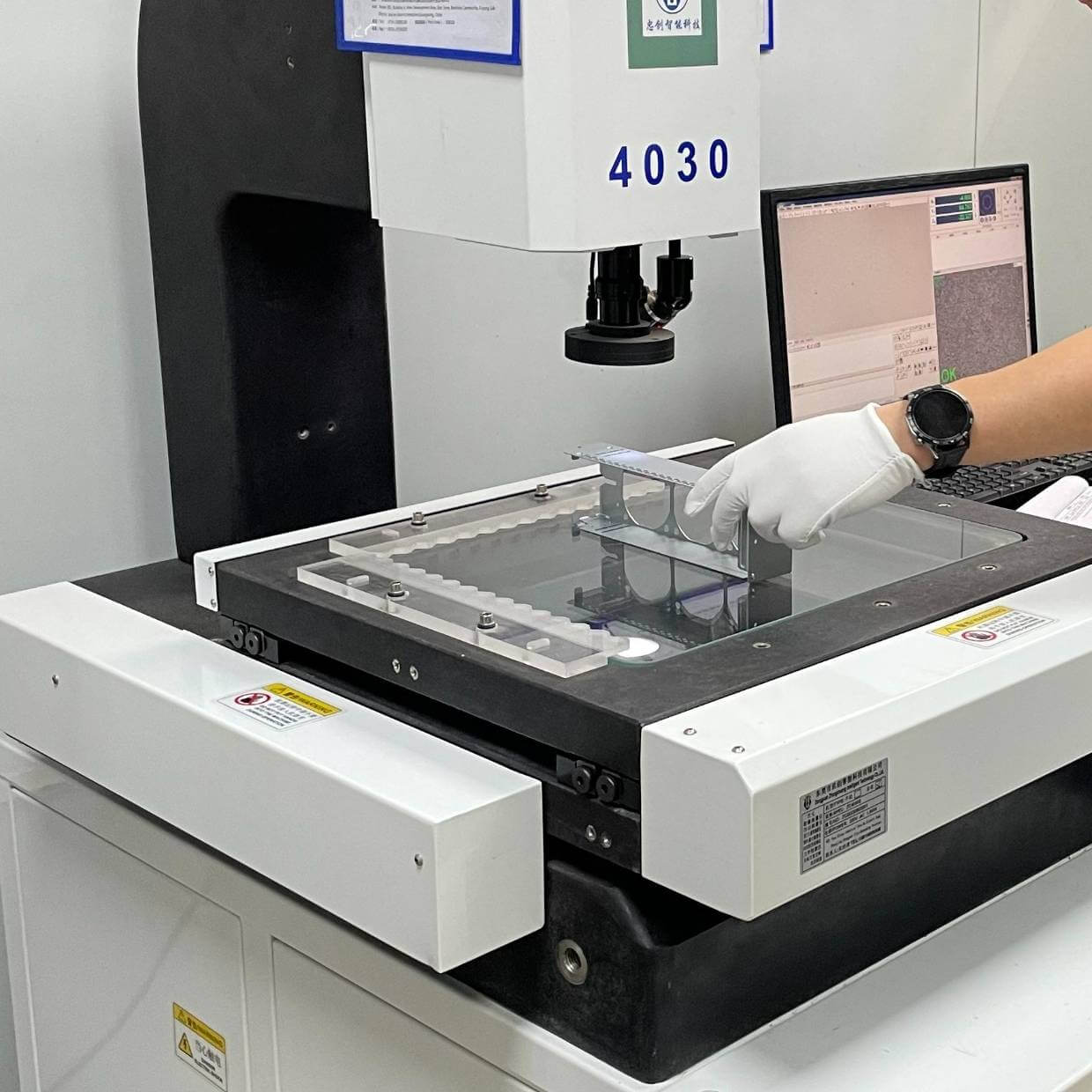

ZH Precision Sheet Metal Processing Quality Assurance

At ZH Precision, quality is our top priority. Every sheet metal part undergoes strict inspection and testing throughout the fabrication process, ensuring precision, consistency, and long-term reliability for all applications.

- ZH Precision CNC machining operations are ISO9001 certified.

- Every order includes a standard inspection report for quality verification.

- Detailed dimensional inspection reports can be provided upon request.

- Material certifications and test reports are available for all components.

- Batch inspections follow ISO285 standards to ensure consistency.

- Confidentiality is guaranteed through strict NDA agreements with clients.

ZH Precision Sheet Metal Fabrication Solutions

Rapid Prototyping

ZH Precision provides fast and accurate sheet metal prototyping to help you validate designs before full-scale production. With advanced laser cutting, CNC bending, and welding capabilities, we deliver functional prototypes that match final production quality within days.

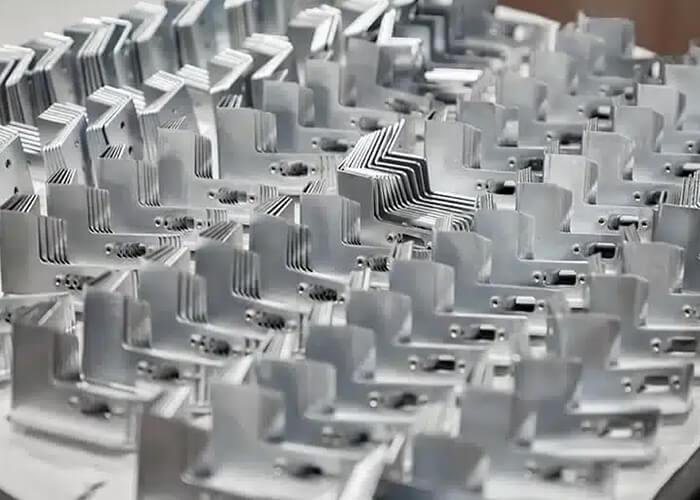

Small-batch production

For pilot runs or limited production needs, we offer flexible small-batch fabrication with consistent precision and short lead times. This service is ideal for testing market response, verifying performance, or bridging the gap between prototype and mass production.

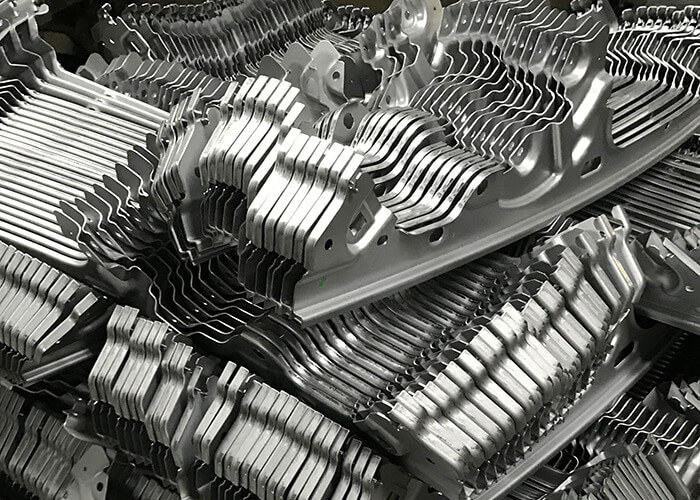

Mass Production

Our automated facilities and strict quality control systems enable efficient, high-volume sheet metal manufacturing. From enclosures to structural components, we ensure repeatable accuracy, competitive pricing, and reliable on-time delivery for large-scale orders.

Available Materials for Sheet Metal Fabrication

| Material | Description |

|---|---|

| Aluminum | Lightweight yet strong, easy to shape, ideal for intricate designs. |

| Copper | Excellent electrical and thermal conductivity with natural corrosion resistance. |

| Brass | Good machinability, distinct appearance, and efficient heat conductivity. |

| Steel | Robust, versatile, and recyclable, ensuring long-lasting performance. |

| Stainless Steel | Durable, stain-resistant, and maintains appearance even in harsh environments. |

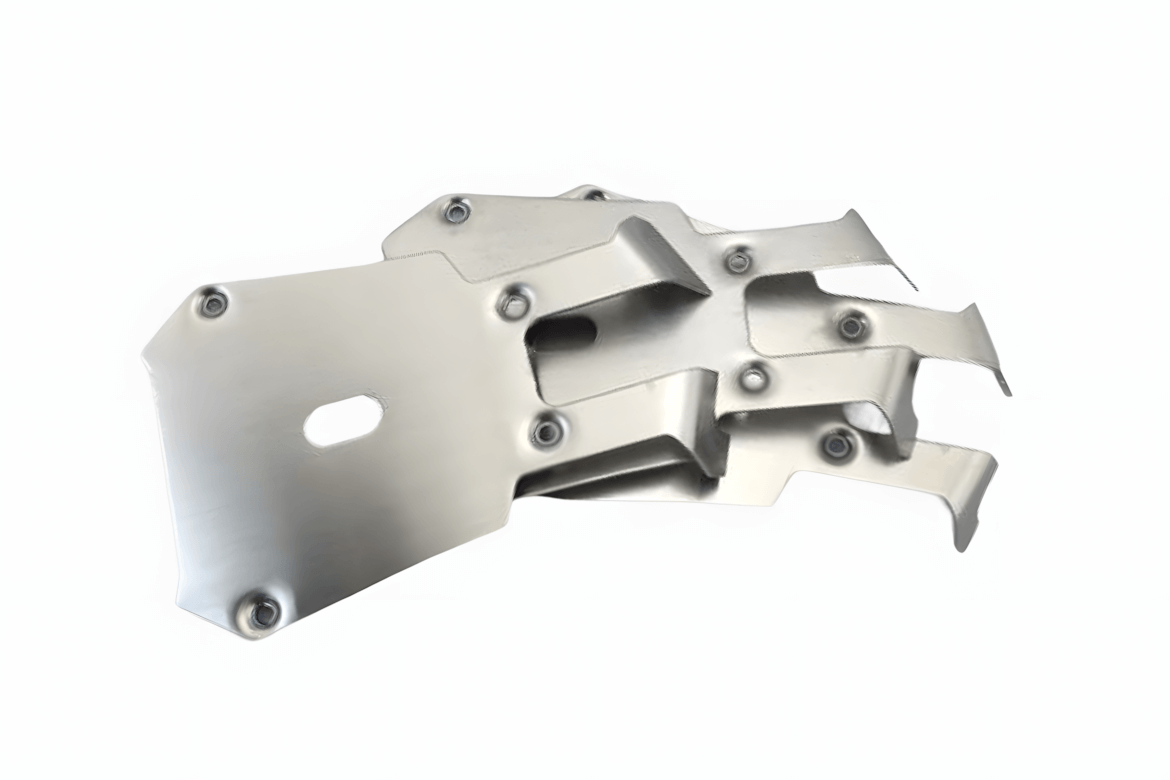

Applications of Sheet Metal Fabrication

Our sheet metal services support a wide range of applications:

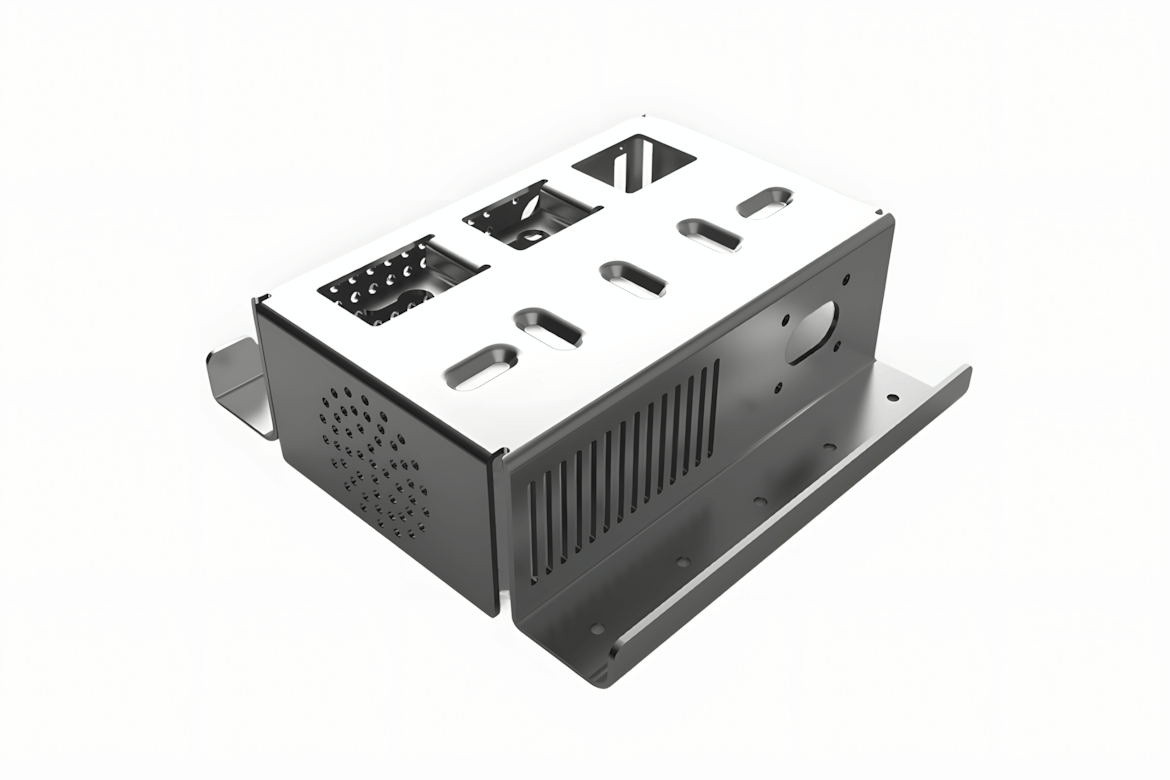

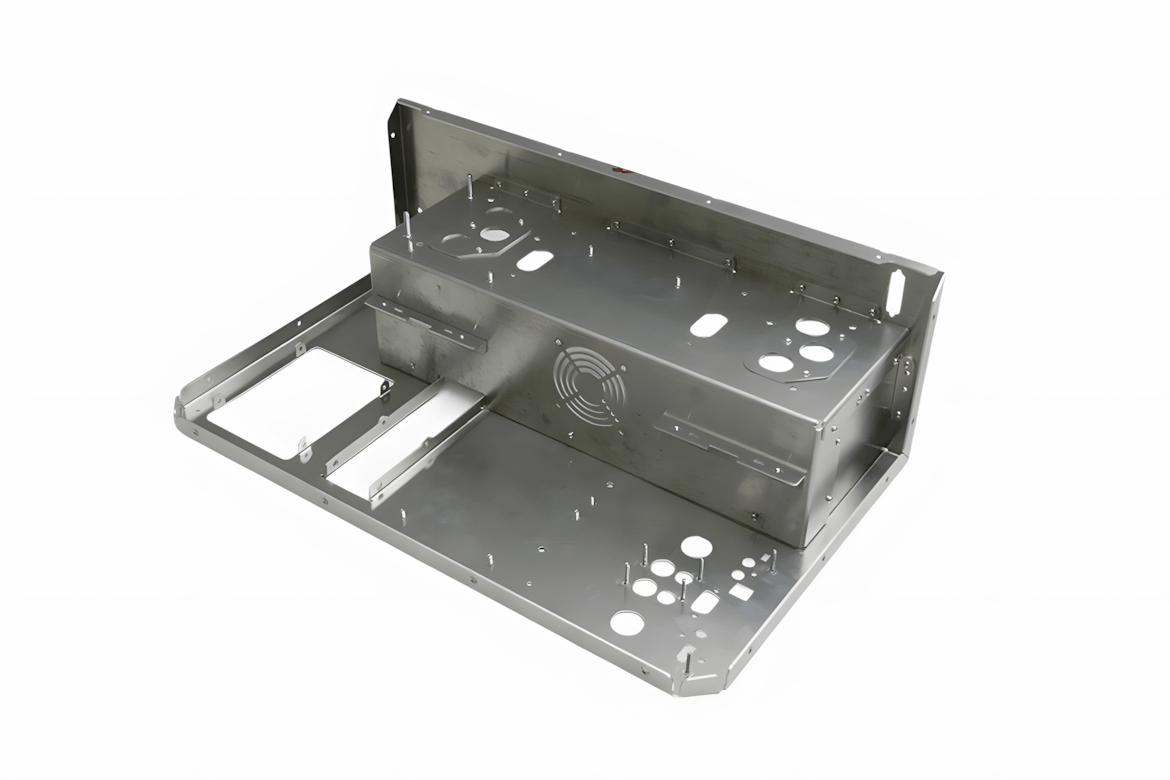

- Protective enclosures and casings

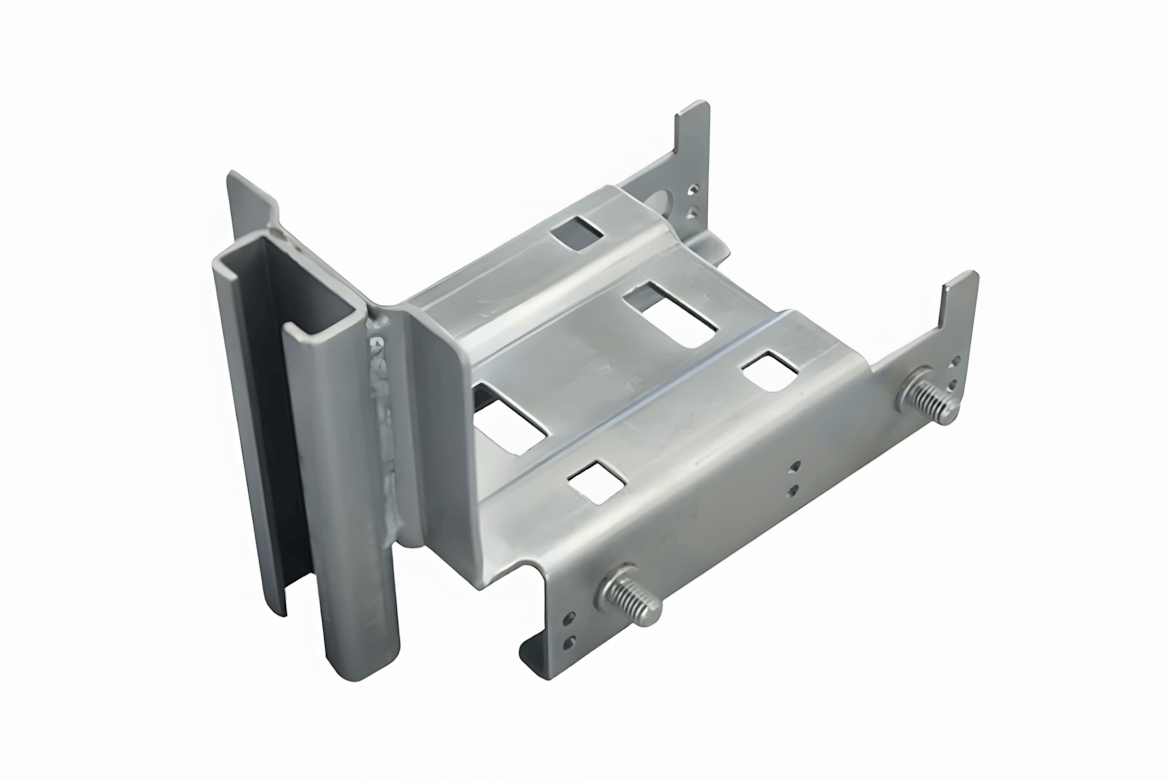

- Structural brackets and mounts

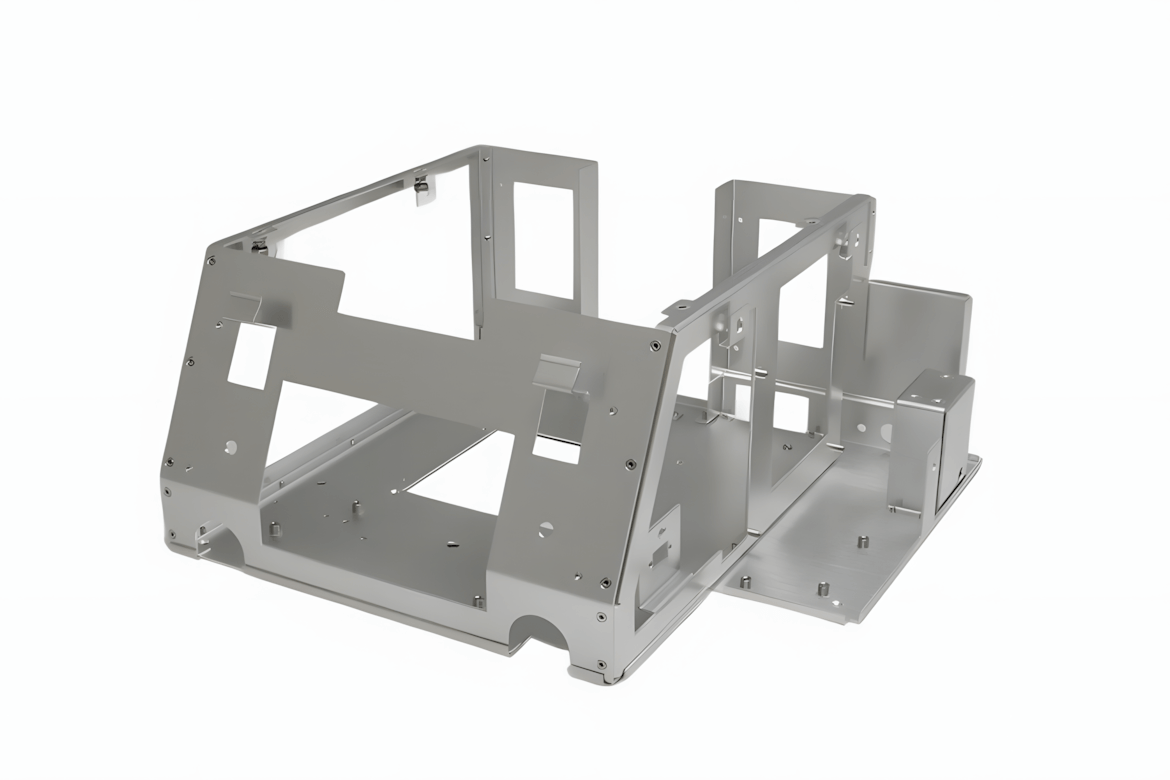

- Vehicle and machinery panels and chassis

- HVAC ductwork and ventilation

- Custom shelving and storage solutions

- Decorative architectural elements

- Rapid prototypes for design testing

Sheet Metal Processing FAQ

Our FAQ section addresses the most common questions from industrial and OEM clients about our sheet metal fabrication services.

A: We accept common CAD file formats such as STEP, IGES, DWG, and DXF files. You may also send 3D models for quotation and production.

A: Delivery times vary depending on complexity and quantity, but typically range from 5 to 15 business days. Expedited production services are available upon request.

Answer: Yes. We offer a variety of surface finishing processes, including oxidation, spraying, painting, sandblasting, and brushing, to meet both aesthetic and functional requirements.

A: We typically process sheet metal thicknesses ranging from 0.5 mm to 10 mm, depending on the material type and part design.

A: Absolutely. We specialize in both small-batch prototyping and large-scale production, ensuring consistent quality and precision at every stage.