How CNC Prototyping Works

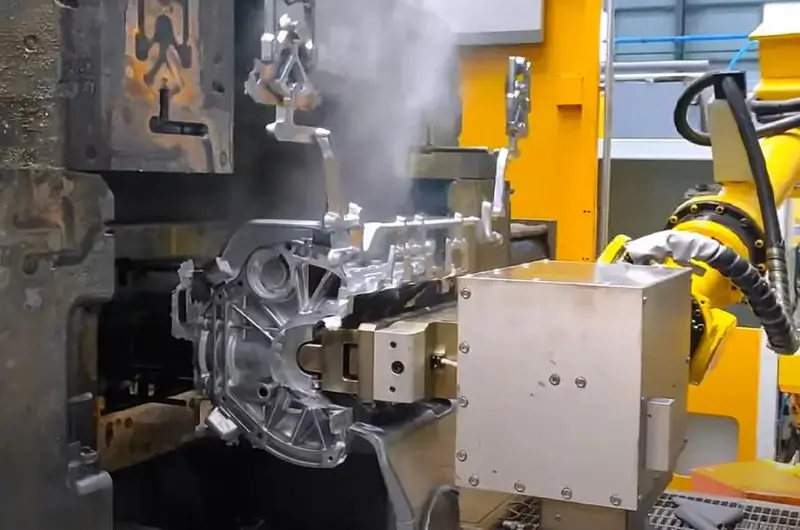

CNC (Computer Numerical Control) prototyping is a process where computer-controlled machinery creates physical prototypes from digital design files. Designers first utilize CAD (Computer-Aided Design) software to create product designs, which are then converted into instructions that CNC machines can understand. The machine leverages precise milling, turning, and multi-axis machining techniques, transforming solid raw materials (such as metal, plastic or composites) into design parts.

For startups and small businesses looking for high-precision and rapid design validation, CNC prototyping provides a reliable solution while maintaining prototype quality and functionality. Whether it’s simple geometric shapes or complex curves, CNC technology achieves extremely high precision and surface finish, making it the ideal tool for quickly validating designs and testing functionality.

Why Choose CNC Prototyping?

CNC prototyping is the go-to technology for many businesses in the design and development process, especially for startups and small enterprises. Applying proper DFM principles ensures your prototypes are efficient to manufacture, cost-effective, and ready for future production. Here’s why CNC prototyping stands out and how it compares to other manufacturing methods:

1. High Precision and Rapid Iteration

For startups, the ability to quickly iterate on designs with high precision is crucial to reducing risk and accelerating product development. CNC technology can transform design concepts into physical prototypes with exceptional accuracy. Whether it’s a complex aerospace component or a consumer electronics shell, CNC delivers consistent and reliable quality.

2. Reliability and Consistency

As projects progress, reliability and consistency are crucial, especially for new businesses. CNC prototyping ensures that every component meets quality standards, making it ideal for large-scale manufacturing processes. The automated nature of CNC reduces human errors and deviations, ensuring precise, repeatable results.

3. Wide Material Compatibility

CNC machining supports a wide range of materials, including metals, plastics, and composite materials. This flexibility allows you to choose the most suitable material for your product’s needs. For small businesses and startups, this means being able to quickly adapt to different product requirements while keeping costs under control.

Cost-Effective for Low-Volume Production

For Low-volume prototyping, CNC machining offers the best cost-effectiveness. Unlike die casting, which requires months to prepare molds and adjust tolerances, CNC prototyping can start production in just a few weeks after design and tolerance confirmation. This makes CNC an ideal solution for projects that require a quick turnaround but don’t involve mass production.

1. Higher Precision Than Alternative Methods

CNC machining provides tighter tolerances than 3D printing, allowing you to create prototypes nearly identical to the final product. This is particularly useful for structural and functional testing. Unlike 3D printed prototypes, CNC prototypes can achieve the fine details and quality required for accurate testing at the early design stages.

2. Seamless Transition from Prototype to Production

CNC machining is not only suitable for prototyping but also seamlessly transitions into mass production, helping businesses move from prototype to full-scale manufacturing. Using the same materials as production parts (such as metals) in the early stages significantly speeds up the manufacturing process.

3. Closer Match to Final Product

CNC prototypes are often more akin the final product in terms of both appearance and functionality when compared to 3D-printed prototypes. CNC machining uses the same materials (such as engineering metals) for prototypes, allowing for early stage testing of the product’s functionality and feasibility. Additionally, CNC machining can replicate other manufacturing processes, like sheet metal forming, enhancing the accuracy of the prototype.

Disadvantages

1. Higher Initial Costs

CNC machining, with higher quality and precision, tends to cost more than 3D printing due to higher equipment costs, and materials (like metals) costs trickling into service charges. The upfront investment can be a limiting factor, especially for projects with tight budgets like small businesses and startups.

2. Material Waste and Environmental Impact

CNC machining is, inherently, a subtractive manufacturing process. As a result, a substantial quantity of material is cut away and turned into waste, and while some waste can be recycled, most cannot be reused, instead requiring further processing. This higher material usage also induces higher material costs, especially when using metals. In comparison to additive manufacturing approaches, such as 3D printing, CNC consumes more resources and energy, resulting in a larger environmental footprint and higher costs when using expensive materials.

Industrial Applications

A substantial number of industries depend on CNC prototyping, for which the latter plays a critical role in delivering highly precise prototypes and designs for rapid design validation and analysis. Industries that leverage CNC technology include, but are not limited to:

- Automotive – Functional prototypes for parts, design optimization, and performance validation

- Aerospace – High-precision, lightweight, high-strength components

- Medical – Precise surgical tools, medical instruments, and implants

- Consumer Electronics – Smartphone cases, laptop shells, and complex component designs

Choosing the Right CNC Prototyping Service Provider

When selecting a CNC prototyping partner, consider factors like equipment capabilities, engineering support, and quality certifications. Look for providers with multi-axis machining capabilities—while 3-axis machines handle basic geometries efficiently, 4-axis and 5-axis machining centers enable production of complex parts with intricate curves, angled surfaces, and features that would otherwise require multiple setups.

Get Your CNC Prototype Quote Now

ZH Precision provides professional CNC prototyping from single prototypes to on-demand small batch production. We ensure precise tolerances, fast delivery, and consistent high-quality results for every part.

Get QuoteAbout Our Services

At ZH Precision, we offer high-quality, fast-turnaround prototyping backed by years of expertise. Our facilities include 3-axis, 4-axis, and 5-axis CNC machining centers, enabling us to handle both simple and complex designs with the precision your project demands.

ZH Precision couples state-of-the-art equipment with professional engineering support. Our team optimizes designs, ensuring manufacturability and quality throughout the process. With ISO9001 certification, we guarantee precision and consistency.

Beyond prototyping, ZH Precision supports smooth transitions from small-batch production to full-scale manufacturing, helping accelerate product development and reduce risks. Whether metal or plastic parts, we offer solutions tailored for success.

Conclusion

CNC prototyping provides a fast, accurate, and cost-effective solution for startups and small businesses looking to validate product designs quickly. While it may require a higher initial investment compared to 3D printing, the precision and quality it offers makes it the ideal choice for projects requiring high-end, reliable prototypes.