Custom Zinc Die Casting Services

ZH Precision specializes in custom zinc die casting, delivering durable, high-precision parts with smooth finishes. From prototype to mass production, we ensure reliable performance and consistent quality for every zinc component.

Verify Certifications On Demand:ISO 9001:2015 | IATF 16949:2016

Home » Zinc die casting

Get a Free DFM Quote

STP I SLDPRT I IPT I PRT I SAT FLES

All uploaded content is secure and confidential.

Zinc Die Casting Engineering Support

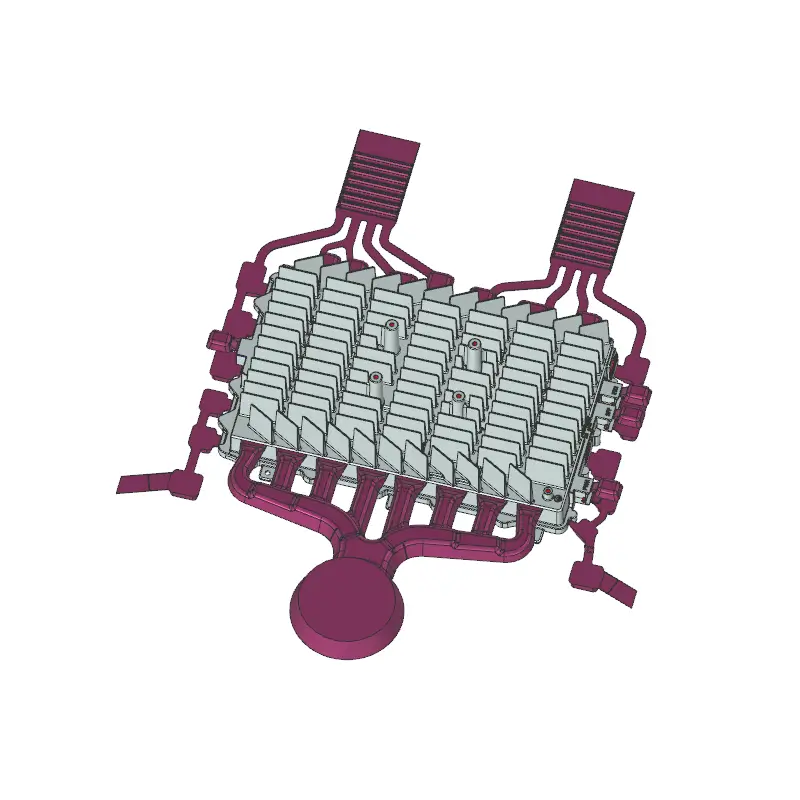

Our engineering team delivers comprehensive technical support across your zinc die casting project lifecycle. Utilizing advanced CAE simulations, mold flow analysis, and CAD/CAM-integrated tooling design, we conduct manufacturability (DFM) reviews and process optimization to predict potential defects, enhance casting performance, and reduce both costs and lead time—ensuring your components achieve optimal quality and performance from concept through production.

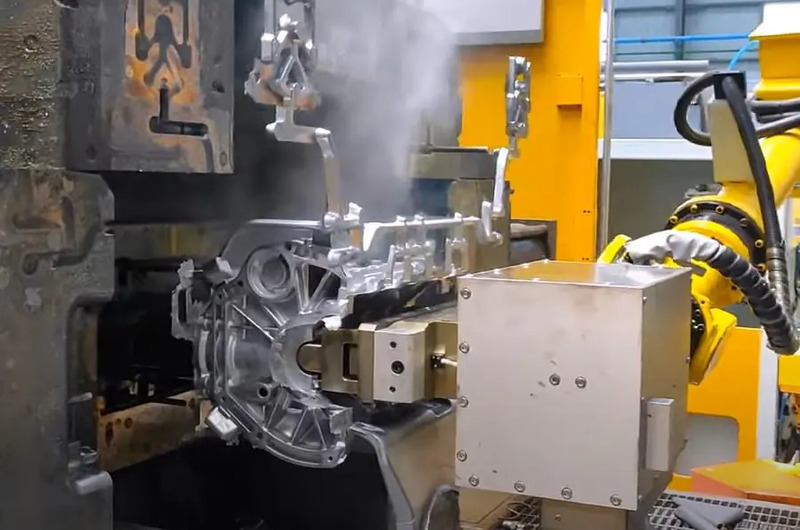

Our Die Casting Factory and Equipment

Our modern die-casting manufacturing center is equipped with over 30 advanced die-casting machines, including a full range of cold-chamber and hot-chamber units from 88T to 2000T. We focus on precise process control, capable of producing components with intricate geometries and ultra-thin walls, ensuring the most stringent project specifications are met.

One-Stop Zinc Die Casting Services

From mold design to finished component delivery, we provide complete zinc die casting solutions. Our expertise spans high-precision casting, efficient production, and tailored finishing—streamlining your supply chain while ensuring quality and cost-effectiveness for both prototype and volume manufacturing needs.

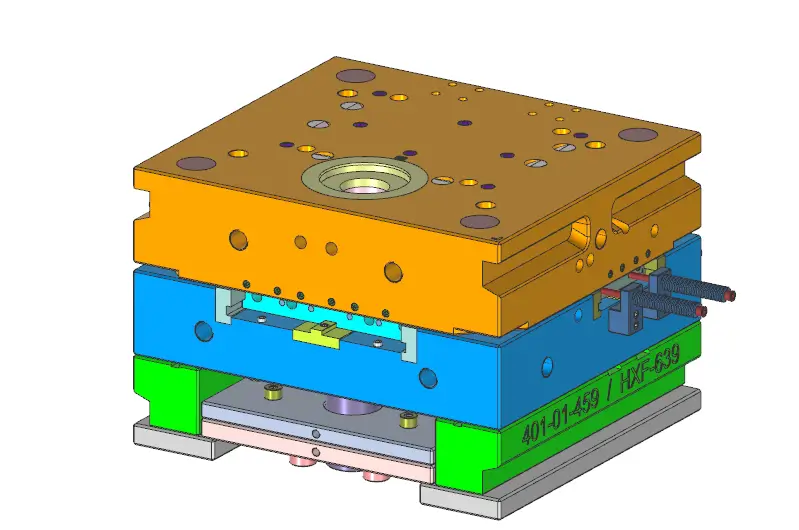

Mold Design & Manufacturing

Die Casting Production

Secondary Processing

CNC Precision Machining

Surface Treatment

Assembly

Zinc Die-Cast Parts Case Studies

Discover ZH Precision’s custom aluminum die cast parts, highlighting precise tolerances, durable performance, and complex designs for automotive, electronics, and industrial applications.

Quality Control of Die-Cast Parts

ZH Precision ensures every die-cast part meets strict quality standards through advanced process monitoring, certified systems, and precision testing.

Quality System

Process Control

Inspection & Testing

Zinc Die-Casting Material

ZH Precision provides precision zinc die casting using alloys such as Zinc Alloy 2, Zamak 3, Zamak 5, Zamak 7, ZA-8, ACuZinc5, EZAC, and ZA-27. These materials offer strength, corrosion resistance, and excellent surface finish, with custom alloys available for specific project needs.

Zinc alloy

Characteristics of Zinc Alloy Materials

Zinc alloys are ideal for small, detailed parts, flowing easily into molds while maintaining tight tolerances. They are durable, cost-effective, and commonly used in electronics, connectors, locks, hardware, and automotive components.

- Zinc Alloy 2

- Zamak 3

- Zamak 5

- Zamak 7

- ZA-8

- EZAC

- ZA-27

High-Gloss Surface Zinc Alloy Decorative Die Casting

Control Focus:

Precise control over alloy purity, mirror-finish mold surfaces, and thermal stability to produce ready-to-plate castings with Ra <0.2μm surface quality. This eliminates secondary polishing and ensures perfect adhesion for chrome, nickel, or PVD coatings in luxury hardware and electronics.

Process Technology:

Using high-purity ZAMAK alloys and premium mirror-polished molds with multi-zone temperature control (±5°C). Optimized lubrication and cooling cycles ensure flawless metal flow and surface replication, delivering Class-A cosmetic surfaces directly from the die.

Miniature Zinc Alloy Connector Housing Die Casting

Control Focus:

Ultra-fine control over shot weight (gram-level), gate vestige, and micro-feature dimensions to ensure precision for automated assembly, perfect pin fitment, and electrical integrity in high-frequency applications.

Process Technology:

Micro-die casting using specialized machines with multi-slide molds forms complex undercuts. A heated manifold delivers consistent, tiny metal shots. In-line vision and laser measurement ensure 100% dimensional verification, enabling production of parts with walls <0.3mm and tolerances within ±0.02mm.

Trusted by Leading Global OEMs

We provide services to world-renowned Original Equipment Manufacturers (OEMs), including FOXCONN, Airspan, ORACLE, JUNIPER, Alnan, and SAGERAN. With consistent quality, reliable machining capabilities, and responsive engineering support, we have become a trusted zinc die-casting manufacturer for high-precision components for communications and electronics.

Why Choose Zinc Die Casting?

Pros of Zinc Die Casting:

- High Precision & Tight Tolerances: Ideal for complex shapes and detailed components with accurate dimensions.

- Excellent Mold Flow: Flows smoothly into molds, making it perfect for thin walls and intricate designs.

- Superior Surface Finish: Smooth cast surfaces reduce the need for secondary finishing operations.

- Cost-Effective for Medium to High Volumes: Optimized for batch production while maintaining quality.

- Strong & Durable: Provides reliable mechanical performance for connectors, electronics, and hardware components.

Cons of Zinc Die Casting:

- Size & Weight Limitations: Best suited for small to medium-sized parts.

- Limited Material Options: Only specific zinc alloys are available.

- Porosity Risks: Air pockets may reduce strength or surface quality.

- High Initial Tooling Costs: Mold and equipment investment is significant.

- Design Constraints: Must follow wall thickness, draft angles, and other casting rules to avoid defects.

What Is Zinc Die Casting?

Zinc die casting is a manufacturing process where molten zinc alloy is injected under high pressure into a steel mold, also known as a die. This process creates strong, precise, and durable parts with excellent surface finishes.

Zinc die casting is ideal for producing complex, detailed components in large quantities—especially for industries like automotive, electronics, and hardware. Zinc alloys flow easily into molds, allowing for thin walls, intricate shapes, and tight tolerances while maintaining strength and dimensional accuracy.

Applications of Zinc Die Casting

Zinc die casting offers high precision, strength, and dimensional stability, making it suitable for diverse industries that demand durable and detailed components. ZH Precision provides tailored die casting solutions for a wide range of applications:

- Automotive Components

Zinc die-cast parts are used in door handles, gear housings, brackets, and decorative trims—offering excellent surface finishes and long-term reliability. - Electronics & Electrical Parts

Ideal for connectors, switch housings, terminal blocks, and compact enclosures that require tight tolerances and thermal stability. - Industrial & Hardware Components

Used for locks, gears, valves, fasteners, and machinery parts where precision, strength, and wear resistance are essential. - Consumer Products

Zinc die casting allows the creation of aesthetically appealing and functional parts such as appliance housings, hardware fittings, and decorative pieces. - Prototyping & Low-Volume Production

ZH Precision also provides custom zinc die-cast prototypes and small-batch manufacturing to support design testing and quick market validation.

Frequently Asked Questions About Zinc Die Casting

Find quick answers to key questions about zinc die casting, from material benefits and design guidelines to surface finishing and production options, to help inform your project decisions.

For further details, our engineering team is ready to assist.

A: Key guidelines include: maintaining uniform wall thickness (recommended 0.8-1.5mm); designing sufficient draft angles (typically 1-2°); using radii/fillets to avoid sharp corners; and designing ribs appropriately to add strength without increasing thickness. Our engineers provide a complimentary Zinc Die Casting DFM Analysis Report.

A: We ensure process stability through fully automated die casting machines, closed-loop temperature control systems, and real-time monitoring. Each production batch follows strict First Article Inspection (FAI) and Statistical Process Control (SPC), with 100% inspection of critical assembly dimensions to guarantee consistency for high-volume production.

A: We support flexible low-volume custom zinc die casting, ideal for product development, market testing, and replacement part supply. We offer rapid prototyping services and can utilize unit die technology to reduce costs for small batches. Typically, there is no strict minimum order quantity requirement.

A: Zinc alloys (especially ZA-8) offer strength close to mild steel, with tensile strength reaching over 400 MPa, coupled with good wear resistance. They are entirely suitable for load-bearing structural parts, such as high-quality furniture hardware, professional tool components, and automotive seat belt buckles.

A: Mold cost primarily depends on part complexity, size, and required mold life. A simple mold for plumbing hardware is less costly, while a complex mold for an electronic enclosure requiring multiple sliders and core pulls is higher. The development lead time is typically 4-6 weeks, including design, machining, trial runs, and modifications.