Custom Zinc Die Casting Services

ZH Precision specializes in custom zinc die casting, delivering durable, high-precision parts with smooth finishes. From prototype to mass production, we ensure reliable performance and consistent quality for every zinc component.

ZH Precision - Your Trusted Zinc Die Casting Manufacturer

With advanced hot-chamber and cold-chamber zinc die casting machines, ZH Precision manufactures complex components with exceptional surface finish and mechanical performance. Our factory provides complete services including mold design, casting, CNC secondary machining, surface finishing, and strict quality control to meet the highest industry standards.

ZH Precision Die Casting Equipment

- 2 – 88 Ton LK Zinc Hot chamber Die Cast Machines

- 1 – 138 Ton RUIDA Zinc Hot chamber Die Cast Machines

- 1 – 280 Ton LK Aluminum cold chamber Die Cast Machine

- 1 – 300 Ton HAITIAN Aluminum cold chamber Die cast machine

- 1 – 400 Ton Aluminum cold chamber Die Cast Machine

- 1 – 500 Ton TOYO Aluminum cold chamber Die Cast Machine

- 1 – 800 Ton LK Aluminium cold chamber Die Cast Machine

- 1 – 1100 Ton UB Aluminum cold chamber Die Cast Machine (Fully Automatic)

- 1 – 1650 Ton YIZUMI Aluminum cold chamber Die Cast Machine

Die Casting Parts Engineering Support

Our expert engineering team provides full technical support from concept design to final production, ensuring every zinc die-cast part meets your expectations for quality, precision, and performance.

Using advanced CAE tools, mold flow simulations, and CAD/CAM integration, we optimize each stage of development — from part design to tooling and manufacturing.

- Using CAE simulation, mold flow analysis, and CAD/CAM integration, we optimize product design, tooling, and casting performance.

- We validate part geometry, predict potential defects, and streamline manufacturing — reducing costs and lead time while maintaining high quality.

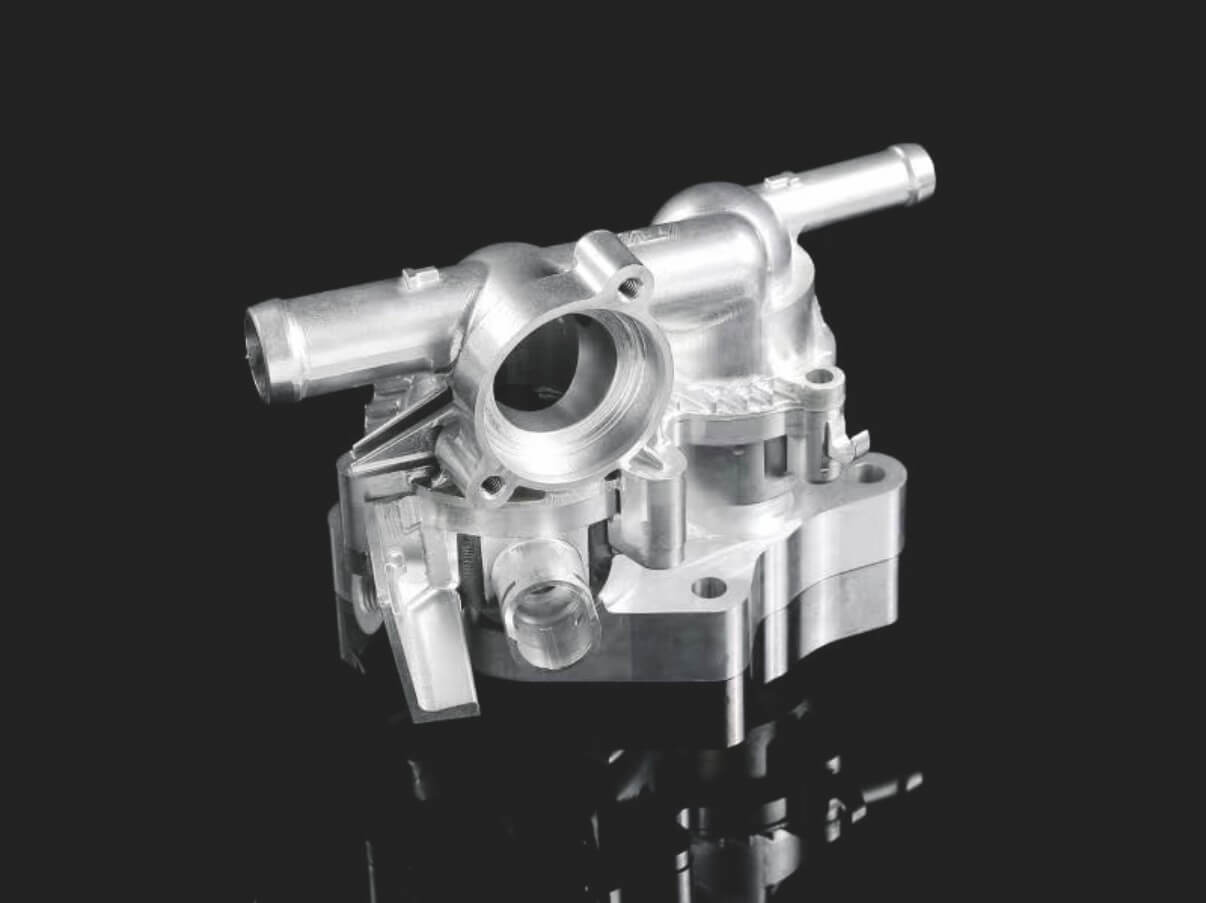

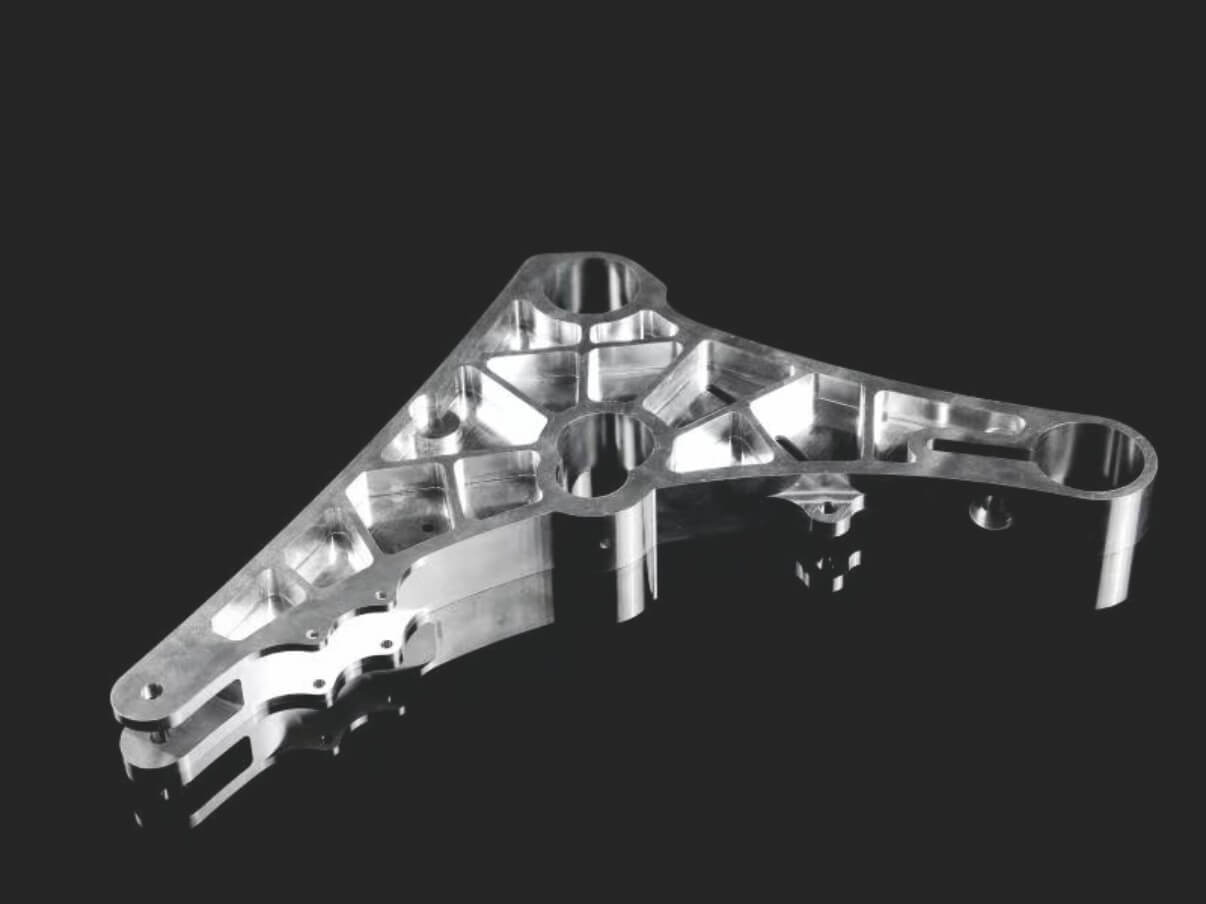

Custom Aluminum Die Cast Parts Gallery

Discover ZH Precision’s custom aluminum die cast parts, highlighting precise tolerances, durable performance, and complex designs for automotive, electronics, and industrial applications.

One-Stop Zinc Die Casting Services

At ZH Precision, we provide complete zinc die casting solutions — from initial design to finished parts. Our in-house engineering, tooling, casting, and finishing capabilities ensure quality, consistency, and fast turnaround under one roof.

Design & Engineering Support

Mold Design & Manufacturing

Die Casting Production

Secondary Machining & Surface Finishing

Assembly & Quality Inspection

Packaging & Logistics

Quality Control of Die-Cast Parts

ZH Precision ensures every die-cast part meets strict quality standards through advanced process monitoring, certified systems, and precision testing.

Quality System

Process Control

Inspection & Testing

Zinc Die-Casting Material

ZH Precision provides precision zinc die casting using alloys such as Zinc Alloy 2, Zamak 3, Zamak 5, Zamak 7, ZA-8, ACuZinc5, EZAC, and ZA-27. These materials offer strength, corrosion resistance, and excellent surface finish, with custom alloys available for specific project needs.

Zinc alloy

Characteristics of Zinc Alloy Materials

Zinc alloys are ideal for small, detailed parts, flowing easily into molds while maintaining tight tolerances. They are durable, cost-effective, and commonly used in electronics, connectors, locks, hardware, and automotive components.

- Zinc Alloy 2

- Zamak 3

- Zamak 5

- Zamak 7

- ZA-8

- EZAC

- ZA-27

Why Choose Zinc Die Casting?

Pros of Zinc Die Casting:

- High Precision & Tight Tolerances: Ideal for complex shapes and detailed components with accurate dimensions.

- Excellent Mold Flow: Flows smoothly into molds, making it perfect for thin walls and intricate designs.

- Superior Surface Finish: Smooth cast surfaces reduce the need for secondary finishing operations.

- Cost-Effective for Medium to High Volumes: Optimized for batch production while maintaining quality.

- Strong & Durable: Provides reliable mechanical performance for connectors, electronics, and hardware components.

Cons of Zinc Die Casting:

- Size & Weight Limitations: Best suited for small to medium-sized parts.

- Limited Material Options: Only specific zinc alloys are available.

- Porosity Risks: Air pockets may reduce strength or surface quality.

- High Initial Tooling Costs: Mold and equipment investment is significant.

- Design Constraints: Must follow wall thickness, draft angles, and other casting rules to avoid defects.

What Is Zinc Die Casting?

Zinc die casting is a manufacturing process where molten zinc alloy is injected under high pressure into a steel mold, also known as a die. This process creates strong, precise, and durable parts with excellent surface finishes.

Zinc die casting is ideal for producing complex, detailed components in large quantities—especially for industries like automotive, electronics, and hardware. Zinc alloys flow easily into molds, allowing for thin walls, intricate shapes, and tight tolerances while maintaining strength and dimensional accuracy.

Applications of Zinc Die Casting

Zinc die casting offers high precision, strength, and dimensional stability, making it suitable for diverse industries that demand durable and detailed components. ZH Precision provides tailored die casting solutions for a wide range of applications:

- Automotive Components

Zinc die-cast parts are used in door handles, gear housings, brackets, and decorative trims—offering excellent surface finishes and long-term reliability. - Electronics & Electrical Parts

Ideal for connectors, switch housings, terminal blocks, and compact enclosures that require tight tolerances and thermal stability. - Industrial & Hardware Components

Used for locks, gears, valves, fasteners, and machinery parts where precision, strength, and wear resistance are essential. - Consumer Products

Zinc die casting allows the creation of aesthetically appealing and functional parts such as appliance housings, hardware fittings, and decorative pieces. - Prototyping & Low-Volume Production

ZH Precision also provides custom zinc die-cast prototypes and small-batch manufacturing to support design testing and quick market validation.