Custom Online CNC Milling Services

Fastest 5 days shipping/100% OQC /3DCMM measurement report/digital model comparison 3D scanning/free returns of defective products

(Signed NDA & SSL encryption)

Home » CNC Milling

3-Axis CNC Milling Services

3-axis CNC milling is one of the most widely used machining processes for manufacturing high-quality CNC milled parts. This process is ideal for simple to moderately complex parts, offering fast setup and flexible production. At ZH Precision, we leverage multiple 3-axis machines simultaneously to meet tight production schedules and ensure efficient, on-time delivery.

Capabilities:

- Maximum Part Size: 2000 × 1500 × 850 mm

- Dimensional Tolerance: ±0.01 mm

- Form Tolerance: 0.03 mm

- Materials: Aluminum, Stainless Steel, Copper, Titanium, Steel, Cast Iron

- Surface Finishing Options: Sandblasting, Anodizing, Electroplating, Passivation, Coating, Spraying, HRC, Stress Relief, Electropolishing

4-Axis CNC Milling Services

4-axis CNC milling is ideal for machining parts that require multiple faces or complex geometries in a single setup. By using a rotary axis in addition to the standard 3 axes, we can mill 3D surfaces with high precision while minimizing the need for multiple clamping operations. This capability improves efficiency, reduces setup time, and ensures consistent quality for medium to high-volume production of custom components.

Capabilities:

- Maximum Part Size: 800 × 400 × 450 mm

- Dimensional Tolerance: ±0.005 mm

- Shape Tolerance: 0.01 mm

- Materials: Aluminum, Stainless Steel, Copper, Titanium, Steel

- Surface Finishing Options: Sandblasting, Anodizing, Electroplating, Passivation, Coating, Spraying, HRC, Stress Relief, Electropolishing

5-Axis CNC Milling Services

5-axis CNC milling enables the precise production of highly complex 3D geometries that are difficult or impossible to achieve with traditional 3- or 4-axis machines. At ZH Precision, our advanced 5-axis milling equipment allows for simultaneous multi-axis machining, minimizing setup time and eliminating the need for multiple clamping operations. This capability ensures exceptional dimensional accuracy, surface quality, and consistency across intricate curved, contoured, and sculpted parts.

Capabilities:

- Maximum Part Size: 650 × 650 × 450 mm

- Dimensional Tolerance: ±0.003 mm

- Form Tolerance: 0.005 mm

- Materials: Aluminum, Stainless Steel, Titanium, Copper, Nickel-based alloys, Inconel, Ferro-nickel alloys, Steel

- Surface Finishing Options: Anodizing, Electroplating, Passivation, Coating, HRC, Stress Relief, EB-Welding, Precision Grinding

low-volume machining services

Zhonghui specializes in low-volume CNC machining, delivering high-precision metal parts for prototypes, pilot runs, and small-batch production. Our flexible approach ensures each component meets strict tolerances and surface quality requirements, while our advanced CNC lathes and mills enable quick turnaround and consistent results. Ideal for clients who need reliable, cost-effective solutions without compromising accuracy or performance.

Low and High-Volume Production

Whether you need small-batch production or large-scale manufacturing, ZH Precision’s CNC milling services ensure consistent accuracy and quality at every stage of production. Our flexible manufacturing capabilities allow us to efficiently handle prototype validation, low-volume custom parts, and full-scale production — all with the same level of precision and attention to detail.

- Precision machining with tolerances as tight as ±0.01 mm across all production volumes.

- Flexible solutions tailored to your specific design and material requirements.

- Fast turnaround times and adaptive scheduling to meet deadlines without compromising quality.

Rapid Metal Forming Services

Whether you need small-batch runs or large-scale manufacturing, Zhonghui’s CNC milling services ensure consistent precision and quality at every production level. Our flexible capabilities allow us to efficiently handle prototype validation, low-volume custom parts, and full-scale production with the same level of accuracy and attention to detail.

- Precision machining with tolerances as tight as ±0.01 mm across all production volumes.

- Flexible solutions tailored to your specific design and material requirements.

- Fast turnaround times and adaptive scheduling to meet deadlines without compromising quality.

CNC Milling Tolerances

At Zhonghui, precision is at the core of every CNC milling project we deliver. Our machining operations strictly follow international tolerance standards—ISO 2768-m for metals and ISO 2768-c for plastics—ensuring dimensional accuracy and consistency across every component. With advanced CNC equipment and rigorous quality inspection procedures, we guarantee each part meets your exact design specifications and performance requirements.

| Specification | 3-Axis | 4-Axis | 5-Axis |

|---|---|---|---|

| Maximum Part Size | 1000 × 500 × 500 mm | 1000 × 500 × 500 mm | 4000 × 1500 × 600 mm |

| Minimum Part Size | 5 × 5 × 5 mm | 5 × 5 × 5 mm | 5 × 5 × 5 mm |

| General Tolerances | ±0.1 mm | ±0.05 mm | ±0.1 mm |

| Lead Time | Delivery of simple parts can be as fast as 3 days. | 7 business days for most projects. | 7 business days for most projects. |

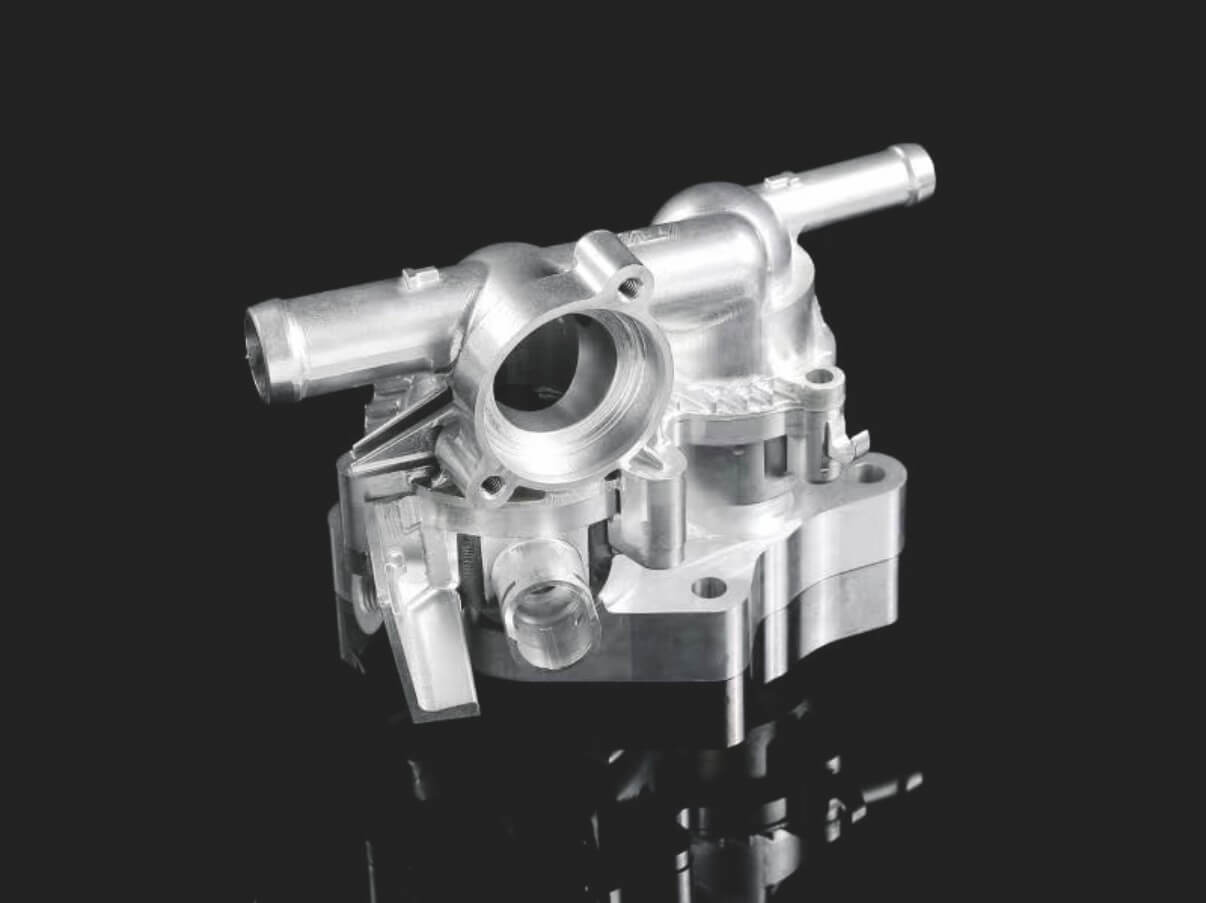

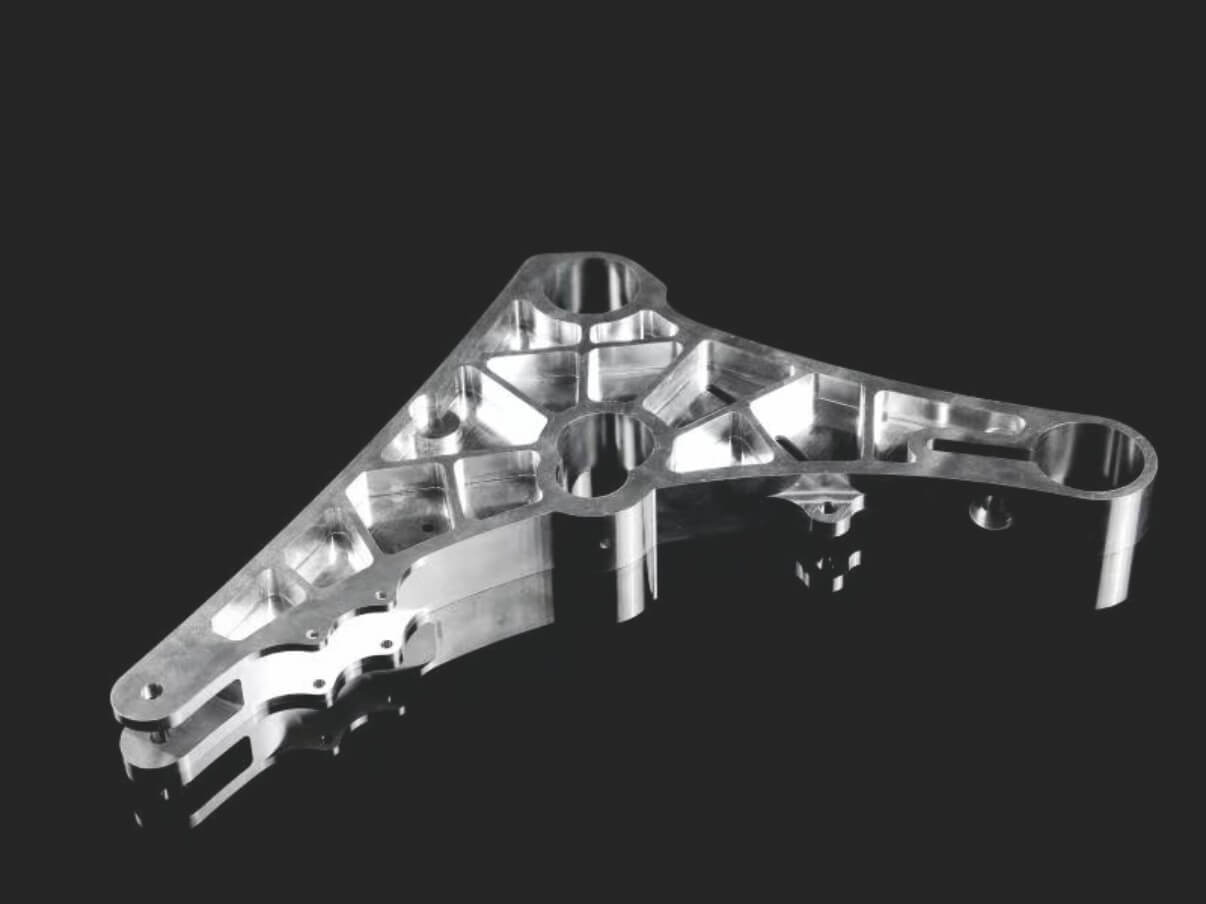

Custom CNC Machined Parts Gallery

Explore our CNC machined components and die cast parts made from aluminum, stainless steel, brass, zinc, and magnesium. We specialize in housings, brackets, heat sinks, enclosures, and connectors for automotive, telecom, aerospace, medical, and industrial applications. All parts are produced with tight tolerances and superior surface finish.

CNC Milling Materials

At ZH Precision, we specialize in high-accuracy CNC milling services for metals such as aluminum, stainless steel, mild steel, titanium, copper, brass, and superalloys.

With advanced 3-, 4-, and 5-axis CNC centers, we deliver precise, high-quality parts with excellent surface finishes and fast turnaround. Trusted by aerospace, automotive, medical, and industrial clients, ZH Precision ensures strict quality control and reliable performance from prototype to production.

Aluminum Alloy

Aluminum alloys are lightweight, strong, and highly machinable, with excellent corrosion resistance and superior thermal and electrical conductivity. They are ideal for aerospace, automotive, electronics, medical devices, and consumer products. Common surface treatments include anodizing, powder coating, polishing, and electroplating for enhanced durability and aesthetics.

Stainless Steel

Stainless steel alloys provide high tensile strength, excellent corrosion and temperature resistance, and good ductility. They are easy to weld, machine, and polish, making them ideal for aerospace, automotive, medical devices, and industrial applications.

Copper

Copper provides excellent thermal and electrical conductivity, making it ideal for electrical components such as busbars and wire connectors. Its natural reddish-orange color and glossy finish also make it suitable for decorative and functional applications.

Titanium

Titanium is a lightweight metal with an excellent strength-to-weight ratio, low thermal expansion, and high corrosion resistance. Its biocompatibility and sterilizability make it ideal for aerospace, automotive, and medical applications.

Mild Steel

Mild steel is a low-carbon alloy with good mechanical strength, high stiffness, and excellent machinability and weldability at low cost. It can be carburized to increase surface hardness, making it ideal for industrial, structural, and general manufacturing applications.

Superalloy

Superalloys offer exceptional high-temperature strength, excellent oxidation and hot corrosion resistance, and superior fatigue and fracture toughness. They are primarily used in aerospace and energy applications where extreme conditions demand reliable performance.

Brass

Brass provides excellent wear resistance, high strength and hardness, and strong chemical corrosion resistance. It is ideal for components such as valves, gears, and precision parts like watch movements.

Alloy steel

Alloy steel provides high strength, excellent toughness, and superior wear and corrosion resistance. It performs reliably under extreme temperatures and can exhibit magnetic properties, making it ideal for industrial and structural applications.

Custom Metal Part Finishing

Transform your CNC machined parts with Zhonghui’s one-stop surface finishing services. We provide a wide selection of finish options—from ultra-smooth polished surfaces to durable protective coatings—that elevate both the appearance and performance of your parts. Our finishing processes enhance corrosion resistance, wear durability, dimensional accuracy, and overall part longevity. Whether you need aesthetic appeal or functional protection, Zhonghui ensures every component meets the highest standards before delivery.

Electroplating

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing

Enhances corrosion resistance and surface hardness while adding color for improved durability and appearance.

Polishing

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

Sand Blasting

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

Tumbling

Tumbling smooths and polishes small parts by friction and abrasion in a barrel, offering a consistent but slightly textured finish.

Electropolish

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Electroplating

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

ZH Quality Assurance

Material Inspection: We carefully verify the materials used for your project, ensuring they meet the desired quality standards and match your specific requirements.

Skilled Workforce: Our experienced and highly skilled machinists and engineers closely monitor every step of the machining process, ensuring each part meets the desired tolerances and specifications.

In-Process Inspection: Throughout the manufacturing process, our quality control team conducts regular inspections and measurements to detect and address any deviations or errors promptly.

Final Inspection: Once the parts are machined and finished, our quality control team performs a thorough final inspection, checking dimensions, surface finish, and other required specifications. This guarantees that each part meets your expectations before shipping.

What is CNC Milling?

CNC milling is a precise manufacturing process. It involves removing material from a workpiece using rotating cutting tools. The process starts with a digital design, usually made using CAD software. Then, this design is converted into a CNC program that controls the movements of the milling machine.

The workpiece is securely fastened to the machine’s table, and the cutting tool, mounted on a spindle, rotates at high speeds. The machine follows the programmed path, making precise cuts to shape the material into the desired form. With high accuracy, CNC milling can create complex shapes and features, like slots, holes, and contours.

Three-axis milling moves the tool along the X, Y, and Z axes. Four-axis milling adds rotation around one axis, while five-axis milling allows rotation around two axes, allowing more intricate designs. This versatility makes CNC milling essential in several industries, from aerospace to medical devices.

Advantages of CNC Milling

High Precision: CNC milling machines can produce parts with very tight tolerances, ensuring high accuracy and consistency in every piece.

Complex Geometries: With the ability to move in multiple axes, CNC milling can create intricate and complex shapes that are difficult or impossible to achieve with manual machining.

Efficiency: Automated operation allows for continuous production, reducing lead times and increasing productivity. Multiple parts can be produced with minimal downtime.

Flexibility: CNC milling can work with a wide range of materials, including metals, plastics, and composites. This versatility makes it suitable for various applications.

Repeatability: Once a design is programmed, the machine can reproduce identical parts over and over, ensuring uniformity and reducing the risk of human error.

Cost-Effective: While the initial setup can be expensive, the efficiency and precision of CNC milling reduce overall production costs, especially for large quantities.

Safety: CNC machines operate with minimal human intervention, reducing the risk of accidents and enhancing workplace safety.

Applications of CNC Milling

Engine Components: Used in the manufacturing of engine blocks, cylinder heads, and pistons, ensuring high performance and durability in automotive and aerospace industries.

Gear Components: Essential for producing gears, splines, and shafts with tight tolerances, used in machinery and automotive applications.

Medical Implants: Creates precise and high-quality implants such as hip joints, dental implants, and surgical screws for the medical field.

Electronic Housings: Produces enclosures for electronic devices, ensuring proper fit and protection for circuit boards and components.

Custom Prototypes: Allows for the rapid development and testing of prototypes, helping designers refine their products before mass production.

Tooling and Dies: Essential for creating molds, dies, and cutting tools used in various manufacturing processes.

Complex Aerospace Parts: Used for producing turbine blades, brackets, and other intricate parts that require high precision and strength.

CNC Milling Services FAQ

ZH Precision provides high-precision CNC milling services for a variety of industries, including automotive, aerospace, and medical. This FAQ section answers common questions about materials, tolerances, surface finishes, and complex part capabilities, helping you understand our expertise and ensure reliable, on-time delivery of custom CNC milled parts.

A:ZH Precision provides CNC milling solutions for automotive, aerospace, medical, electronics, and industrial equipment sectors, delivering high-precision, custom components for diverse applications.

A: Yes, we hold ISO 9001 and IATF 16949 certifications, ensuring that automotive CNC milled components meet strict quality and compliance standards.

A: We implement strict quality control through 3D model verification, full-dimensional measurement, FMEA/PFMEA analysis, and in-process inspections to guarantee accuracy and consistency.

A: Yes, our advanced 3-, 4-, and 5-axis CNC milling machines allow us to manufacture complex multi-face geometries, curved surfaces, and intricate features in a single setup.

A: We provide sandblasting, anodizing, electroplating, passivation, coating, polishing, and stress relief to enhance both aesthetics and functional durability.