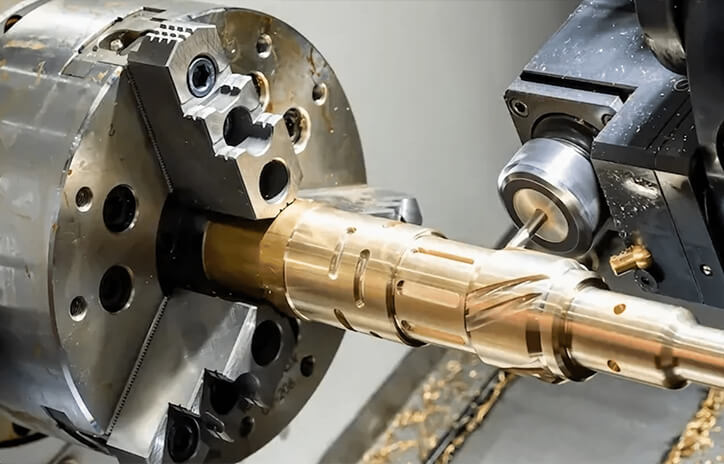

CNC Turning Services

Fastest 5 days shipping/100% OQC /3DCMM measurement report/digital model comparison 3D scanning/free returns of defective products

(Signed NDA & SSL encryption)

Home » CNC Turning

Online Custom CNC Turning Services

利用中辉提供的按需数控车削服务,您可以获得量身定制的高品质金属零件。我们采用先进的数控车床和动力刀具,能够加工具有复杂几何形状(例如径向和轴向孔、沟槽和槽)的精密零件,所有零件的公差均可控制在±0.01毫米以内。无论是原型制作还是批量生产,我们的自动化系统都能确保质量稳定、交货迅速(最快1天),并为简单或复杂的圆柱形零件提供经济高效的解决方案。

low-volume machining services

Zhonghui specializes in low-volume CNC machining, delivering high-precision metal parts for prototypes, pilot runs, and small-batch production. Our flexible approach ensures each component meets strict tolerances and surface quality requirements, while our advanced CNC lathes and mills enable quick turnaround and consistent results. Ideal for clients who need reliable, cost-effective solutions without compromising accuracy or performance.

Low and High-Volume Production

Whether you need small-batch production or large-scale manufacturing, ZH Precision’s CNC milling services ensure consistent accuracy and quality at every stage of production. Our flexible manufacturing capabilities allow us to efficiently handle prototype validation, low-volume custom parts, and full-scale production — all with the same level of precision and attention to detail.

- Precision machining with tolerances as tight as ±0.01 mm across all production volumes.

- Flexible solutions tailored to your specific design and material requirements.

- Fast turnaround times and adaptive scheduling to meet deadlines without compromising quality.

Rapid Metal Forming Services

Whether you need small-batch runs or large-scale manufacturing, Zhonghui’s CNC milling services ensure consistent precision and quality at every production level. Our flexible capabilities allow us to efficiently handle prototype validation, low-volume custom parts, and full-scale production with the same level of accuracy and attention to detail.

- Precision machining with tolerances as tight as ±0.01 mm across all production volumes.

- Flexible solutions tailored to your specific design and material requirements.

- Fast turnaround times and adaptive scheduling to meet deadlines without compromising quality.

Tolerances for CNC Turning

Zhonghui provides precision CNC turning services with tight tolerances up to ±0.005”. As an ISO 9001 certified manufacturer, we ensure high-quality CNC lathe parts for both metals and plastics, following ISO 2768-m for metals and ISO 2768-c for plastics. Reliable accuracy and consistency across all production volumes.

| Title | Description |

|---|---|

| Maximum Part Size | Typically up to 500 mm in diameter and 1500 mm in length, though larger sizes can be accommodated with specific equipment. |

| Minimum Part Size | As small as 1 mm in diameter, depending on the material and machining setup. |

| General Tolerances | Standard tolerances of ±0.01 mm; tighter tolerances down to ±0.005 mm can be achieved based on the material and complexity of the part. |

| Lead Time | Standard lead times range from 5-10 days for small batches. |

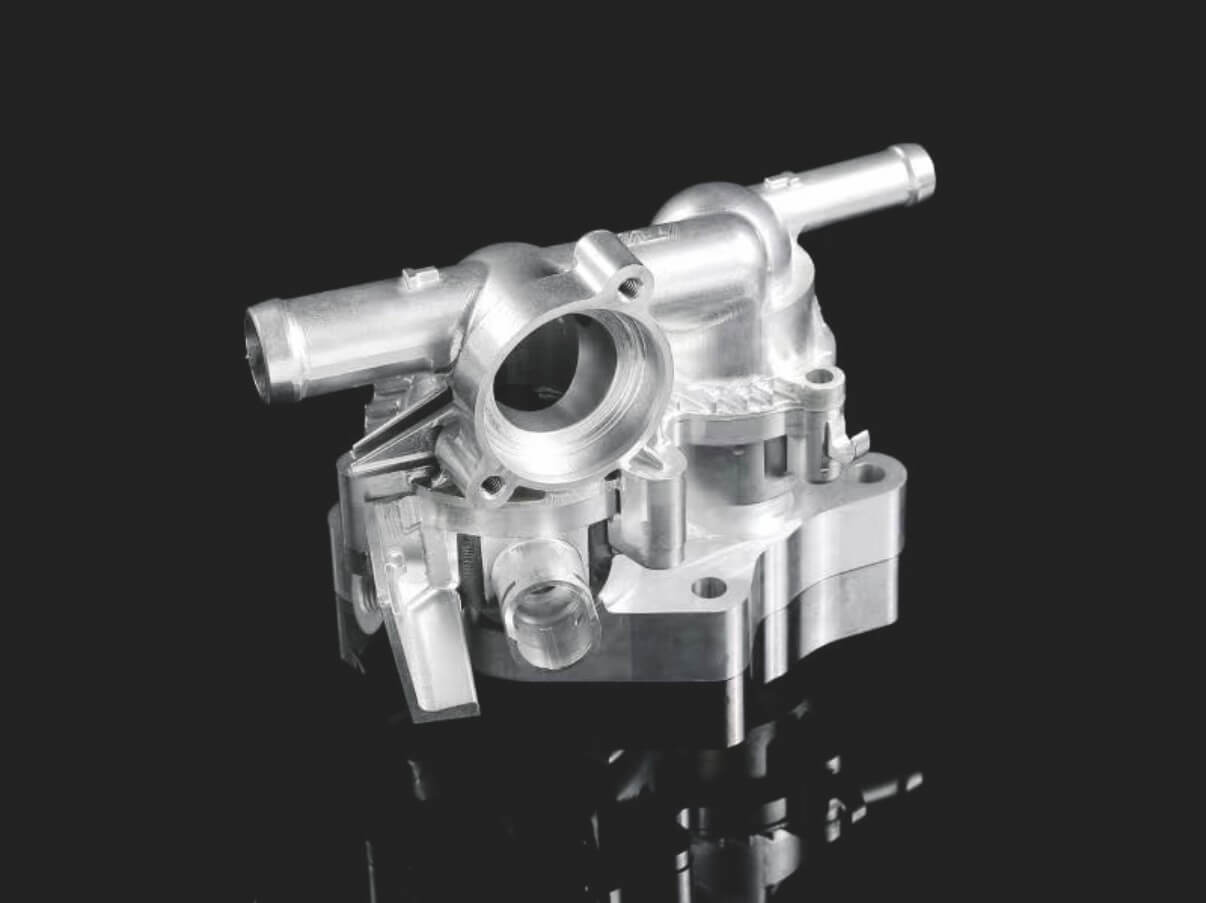

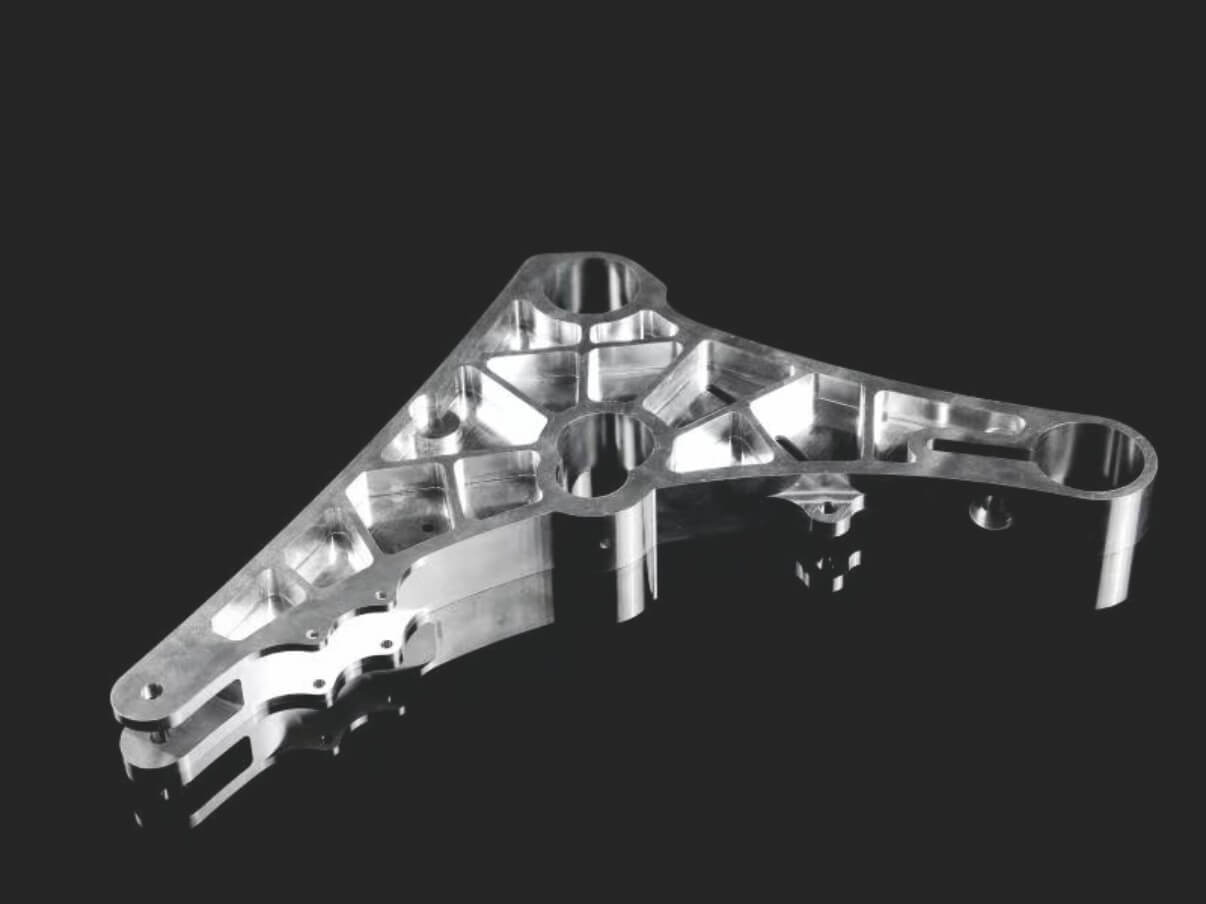

Custom CNC Machined Parts Gallery

Explore our CNC machined components and die cast parts made from aluminum, stainless steel, brass, zinc, and magnesium. We specialize in housings, brackets, heat sinks, enclosures, and connectors for automotive, telecom, aerospace, medical, and industrial applications. All parts are produced with tight tolerances and superior surface finish.

CNC Turning Materials

ZH Precision specializes in CNC turning of metal materials. We handle a wide range of metals, including aluminum, stainless steel, mild steel, titanium, copper, brass, and superalloys. Our advanced CNC lathes ensure high precision, excellent surface finish, and consistent quality for prototypes, low-volume batches, and full-scale production. Every part is machined to tight tolerances, delivering reliable performance for your custom metal components.

Aluminum Alloy

Aluminum alloys are lightweight, strong, and highly machinable, with excellent corrosion resistance and superior thermal and electrical conductivity. They are ideal for aerospace, automotive, electronics, medical devices, and consumer products. Common surface treatments include anodizing, powder coating, polishing, and electroplating for enhanced durability and aesthetics.

Stainless Steel

Stainless steel alloys provide high tensile strength, excellent corrosion and temperature resistance, and good ductility. They are easy to weld, machine, and polish, making them ideal for aerospace, automotive, medical devices, and industrial applications.

Copper

Copper provides excellent thermal and electrical conductivity, making it ideal for electrical components such as busbars and wire connectors. Its natural reddish-orange color and glossy finish also make it suitable for decorative and functional applications.

Titanium

Titanium is a lightweight metal with an excellent strength-to-weight ratio, low thermal expansion, and high corrosion resistance. Its biocompatibility and sterilizability make it ideal for aerospace, automotive, and medical applications.

Mild Steel

Mild steel is a low-carbon alloy with good mechanical strength, high stiffness, and excellent machinability and weldability at low cost. It can be carburized to increase surface hardness, making it ideal for industrial, structural, and general manufacturing applications.

Superalloy

Superalloys offer exceptional high-temperature strength, excellent oxidation and hot corrosion resistance, and superior fatigue and fracture toughness. They are primarily used in aerospace and energy applications where extreme conditions demand reliable performance.

Brass

Brass provides excellent wear resistance, high strength and hardness, and strong chemical corrosion resistance. It is ideal for components such as valves, gears, and precision parts like watch movements.

Alloy steel

Alloy steel provides high strength, excellent toughness, and superior wear and corrosion resistance. It performs reliably under extreme temperatures and can exhibit magnetic properties, making it ideal for industrial and structural applications.

Custom CNC Turning Finishes

ZH Precision ensures every CNC-turned part is delivered with consistent quality, tight tolerances, and enhanced corrosion resistance, wear durability, and dimensional accuracy, making components reliable for industrial, aerospace, automotive, and medical applications.

Electroplating

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing

Enhances corrosion resistance and surface hardness while adding color for improved durability and appearance.

Polishing

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

Sand Blasting

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

Tumbling

Tumbling smooths and polishes small parts by friction and abrasion in a barrel, offering a consistent but slightly textured finish.

Electropolish

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Electroplating

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

Why Choose ZH Precision?

Lorem ipsum dolor sat amet,consectetur adipiscing elit。 Ut elittellus,luctus nec ullamcorper mattis,pulvinar dapibus leo。

1. Advanced CNC Turning Capabilities

2.End-to-End CNC Turning Solutions

3. Experienced CNC Engineers

4. Mastering Complex CNC Turning Projects

What is CNC Turning?

CNC turning is a precision manufacturing process that uses computer-controlled lathes to shape metal parts into cylindrical forms. The process begins with a CAD-designed model, which is translated into machine instructions via CAM software. A cylindrical workpiece is secured in the machine’s chuck, and cutting tools move along multiple axes to perform operations such as facing, threading, knurling, drilling, and grooving. Coolant is applied to prevent overheating and remove debris. After machining, parts can undergo finishing processes like polishing or sanding, followed by thorough inspection to ensure all dimensions and tolerances are met. CNC turning offers high precision, repeatability, and efficiency, making it ideal for producing complex metal components.

Advantages of CNC Milling

High Precision: CNC milling machines can produce parts with very tight tolerances, ensuring high accuracy and consistency in every piece.

Complex Geometries: With the ability to move in multiple axes, CNC milling can create intricate and complex shapes that are difficult or impossible to achieve with manual machining.

Efficiency: Automated operation allows for continuous production, reducing lead times and increasing productivity. Multiple parts can be produced with minimal downtime.

Flexibility: CNC milling can work with a wide range of materials, including metals, plastics, and composites. This versatility makes it suitable for various applications.

Repeatability: Once a design is programmed, the machine can reproduce identical parts over and over, ensuring uniformity and reducing the risk of human error.

Cost-Effective: While the initial setup can be expensive, the efficiency and precision of CNC milling reduce overall production costs, especially for large quantities.

Safety: CNC machines operate with minimal human intervention, reducing the risk of accidents and enhancing workplace safety.

Applications of CNC Milling

Engine Components: Used in the manufacturing of engine blocks, cylinder heads, and pistons, ensuring high performance and durability in automotive and aerospace industries.

Gear Components: Essential for producing gears, splines, and shafts with tight tolerances, used in machinery and automotive applications.

Medical Implants: Creates precise and high-quality implants such as hip joints, dental implants, and surgical screws for the medical field.

Electronic Housings: Produces enclosures for electronic devices, ensuring proper fit and protection for circuit boards and components.

Custom Prototypes: Allows for the rapid development and testing of prototypes, helping designers refine their products before mass production.

Tooling and Dies: Essential for creating molds, dies, and cutting tools used in various manufacturing processes.

Complex Aerospace Parts: Used for producing turbine blades, brackets, and other intricate parts that require high precision and strength.

Frequently Asked Questions

Still have questions? Click to view the FAQ page, there are more common questions for you to answer! Contact our team is ready to help you.

答:马赛克报警器是一家专业的报警系统制造商,专注于个人报警器和家庭报警系统的研究、开发和生产。

答:我们的产品已获得国际认证,包括CE、FCC和RoHS,以确保符合全球市场的安全和环境标准。

答:是的,我们提供OEM(原始设备制造)和ODM(原始设计制造)服务,以满足客户的个性化需求。

答:我们的生产能力每月达数万件产品,具体产量将根据订单需求进行调整。

答:我们的产品广泛覆盖个人安全、家庭安全、商业安全、户外活动、医疗行业等人群领域,为用户提供全面的安全解决方案。