Custom 5-Axis CNC Machining Services

Delivery in as little as 5 days

100% shipment inspection

Full Process Measurement Report

3D Scanning Digital Model Comparison

Free return of defective products

Home » 5-axis CNC machining

Custom 5-Axis CNC Machining Manufacturer

ZH Precision is a leading custom 5-axis CNC machining manufacturer, specializing in delivering high-precision, complex metal components for industries such as aerospace, automotive, medical, and industrial equipment. With over 15 years of machining experience, we offer complete in-house production — from material inspection and advanced 5-axis CNC milling to precision grinding, heat treatment, and surface finishing.

Our skilled engineers ensure every component meets strict quality standards through 3D model verification and full-dimensional inspection. Whether you need rapid prototyping, low-volume production, or full-scale manufacturing, ZH Precision guarantees fast turnaround, reliable precision, and consistent quality, making us a trusted partner for custom, high-performance CNC machined solutions.

ZH Precision 5-Axis CNC Machining Capabilities

ZH Precision specializes in high-precision 5-axis CNC machining, delivering complex metal components with tight tolerances, consistent quality, and fast turnaround. With over 15 years of experience, we serve industries such as aerospace, automotive, medical, electronics, industrial equipment, and energy, supporting both rapid prototyping and low- to high-volume production.

- Aerospace: turbine blades, brackets, airframe structural parts, combustion chamber components

- Automotive: engine blocks, crankshafts, transmission parts, wheel hubs

- Medical devices: hip and knee implants, dental implants, surgical instruments

- Industrial equipment: pumps, valves, molds, precision jigs

- Electronics & optics: enclosures, brackets, heat sinks, precision assemblies

- Energy & power: wind turbine blade supports, motor housings, gas turbine parts

- Prototypes: functional prototypes, complex surface models for testing

5-Axis CNC Machining Capability

ZH Precision specializes in ultra-precision 5-axis CNC machining, delivering components with tight tolerances and exceptional dimensional stability. Our standard tolerances achieve ISO 2768-m for metals, ensuring complex geometries and intricate features are machined with consistent accuracy.

5-Axis CNC Machined Parts Control

ZH Precision leverages 5-axis CNC machining to perform multi-face machining in a single setup, minimizing clamping errors and ensuring tight dimensional tolerances. Our process control focuses on surface contour, straightness, coaxiality, total runout, positional accuracy, and dynamic balancing. By carefully managing internal stresses, material hardness, and surface treatments, we ensure every part achieves consistent precision, mechanical performance, and readiness for demanding industrial, aerospace, automotive, and medical applications.

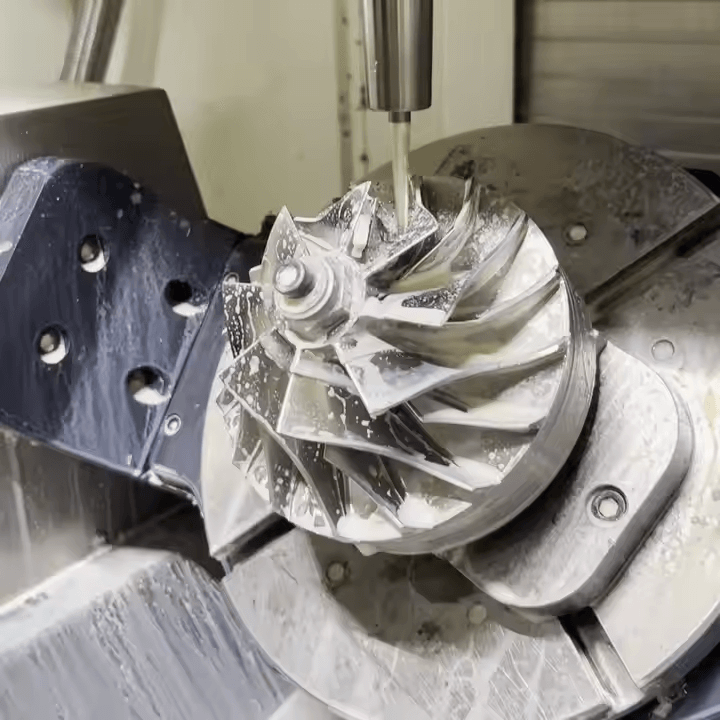

Aluminum Impeller 5-Axis Machining

Control Focus:

ZH Precision ensures tight control of outer contours, shaft centerline runout, and assembly fit, with high requirements for dynamic balancing and centrifugal forces. This guarantees bearing life, smooth operation, minimal noise, and optimal rotational performance.

Process Technology:

We combine CNC turning and 5-axis milling to produce high-precision aluminum impellers. Blanks are turned with finishing allowances, then 5-axis milled to achieve tight roundness and exact blade geometry. All machining uses a single coordinate system for the shaft and outer surfaces, ensuring consistent accuracy, minimal stress, and superior aerodynamic performance.

High-Temperature Alloy Impeller 5-Axis CNC Machining

Control Focus:

ZH Precision specializes in 5-axis CNC machining of high-temperature alloys such as Invar. These materials are tough, have low thermal conductivity, and are prone to hardening and deformation during cutting. We carefully control shaft runout, blade geometry, and critical dimensions, using ultra-durable coated tools and low-temperature cutting fluids to minimize heat and maintain precision. Electron beam welding, stress relief, and precision grinding further ensure structural integrity and reliable performance.

Process Technology:

Impellers are machined from CNC-turned blanks and finished with 5-axis milling. For larger production, casting blanks are recommended to optimize material usage, roughing efficiency, and tool life. This workflow ensures tight tolerances, smooth surfaces, and consistent quality for high-temperature alloy impellers used in aerospace, energy, and industrial applications.

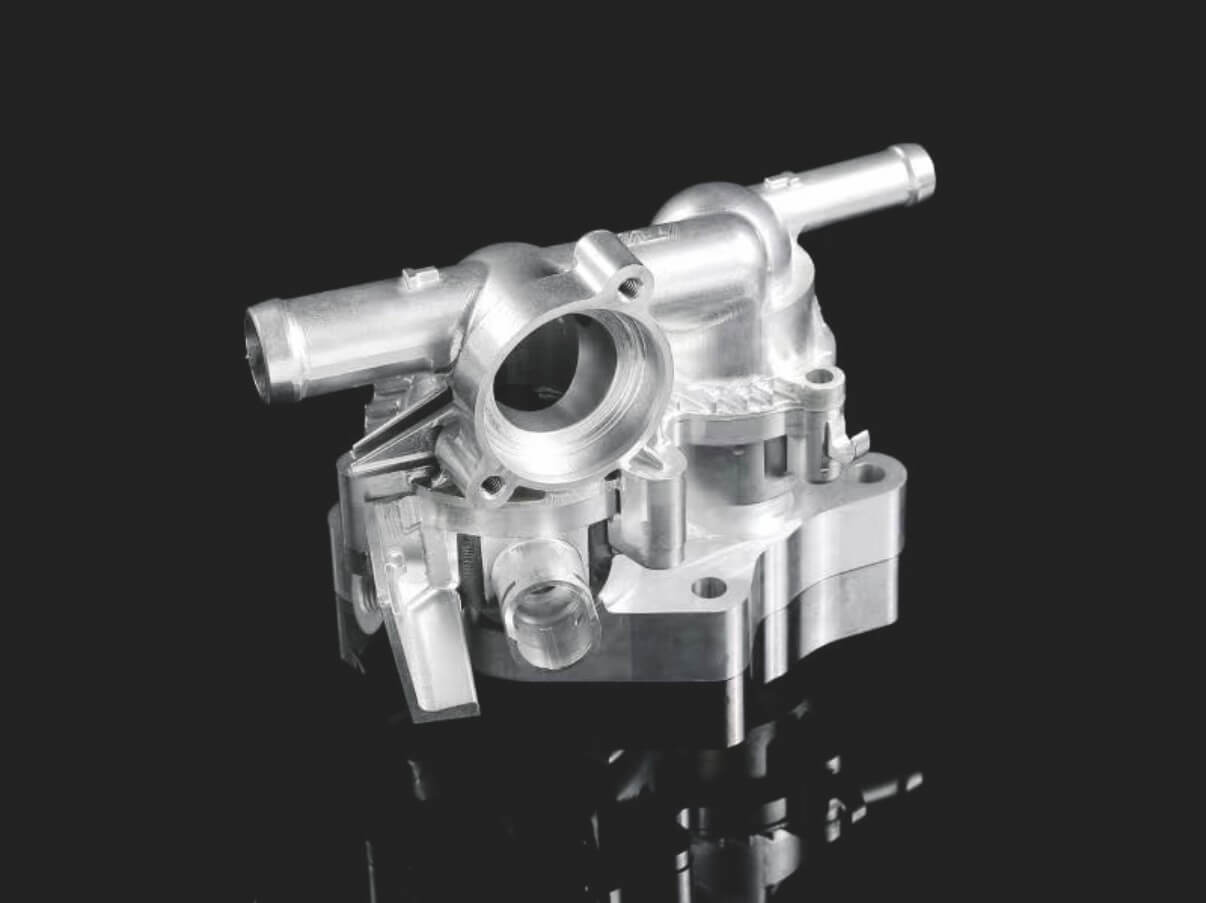

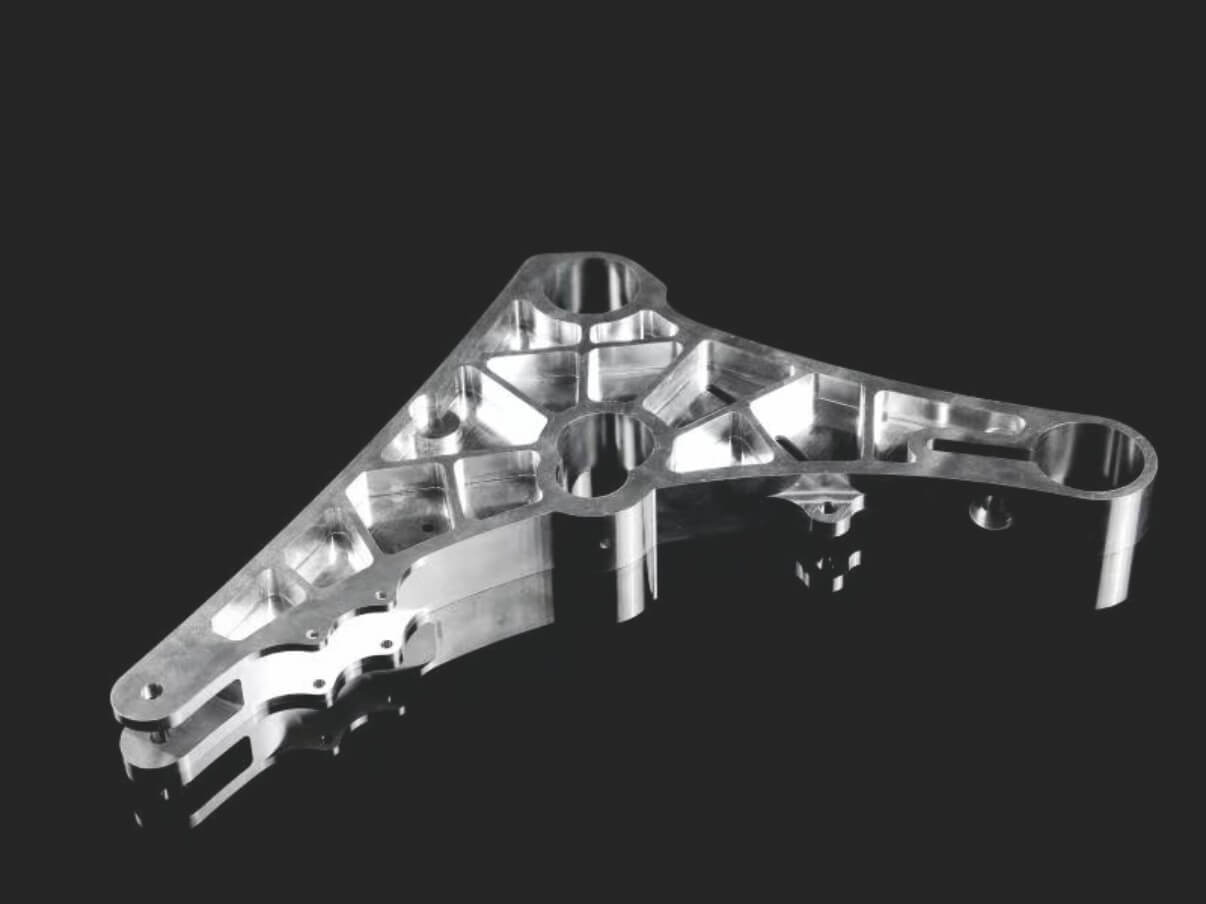

Custom CNC Machined Parts Gallery

Explore our CNC machined components and die cast parts made from aluminum, stainless steel, brass, zinc, and magnesium. We specialize in housings, brackets, heat sinks, enclosures, and connectors for automotive, telecom, aerospace, medical, and industrial applications. All parts are produced with tight tolerances and superior surface finish.

5-Axis CNC Machining Materials

ZH Precision utilizes advanced 5-axis CNC machining to deliver precision components from aluminum, brass, and titanium alloys. Our custom parts achieve tight tolerances up to ±0.01mm and surface finishes as smooth as Ra≤0.8μm, making them ideal for aerospace, medical, and automation applications. Using 5-axis interpolation, we can machine complex geometries in a single setup, reducing setup time and eliminating multi-clamp errors. From prototyping to low- and medium-volume production, our comprehensive quality control ensures efficient, reliable, and high-precision delivery.

Aluminum Alloy

Aluminum alloys are lightweight, strong, and highly machinable, with excellent corrosion resistance and superior thermal and electrical conductivity. They are ideal for aerospace, automotive, electronics, medical devices, and consumer products. Common surface treatments include anodizing, powder coating, polishing, and electroplating for enhanced durability and aesthetics.

Stainless Steel

Stainless steel alloys provide high tensile strength, excellent corrosion and temperature resistance, and good ductility. They are easy to weld, machine, and polish, making them ideal for aerospace, automotive, medical devices, and industrial applications.

Copper

Copper provides excellent thermal and electrical conductivity, making it ideal for electrical components such as busbars and wire connectors. Its natural reddish-orange color and glossy finish also make it suitable for decorative and functional applications.

Titanium

Titanium is a lightweight metal with an excellent strength-to-weight ratio, low thermal expansion, and high corrosion resistance. Its biocompatibility and sterilizability make it ideal for aerospace, automotive, and medical applications.

Mild Steel

Mild steel is a low-carbon alloy with good mechanical strength, high stiffness, and excellent machinability and weldability at low cost. It can be carburized to increase surface hardness, making it ideal for industrial, structural, and general manufacturing applications.

Superalloy

Superalloys offer exceptional high-temperature strength, excellent oxidation and hot corrosion resistance, and superior fatigue and fracture toughness. They are primarily used in aerospace and energy applications where extreme conditions demand reliable performance.

Brass

Brass provides excellent wear resistance, high strength and hardness, and strong chemical corrosion resistance. It is ideal for components such as valves, gears, and precision parts like watch movements.

Alloy steel

Alloy steel provides high strength, excellent toughness, and superior wear and corrosion resistance. It performs reliably under extreme temperatures and can exhibit magnetic properties, making it ideal for industrial and structural applications.

Surface Treatment for Custom-Processed Parts

ZH Precision provides one-stop surface finishing solutions for 5-axis CNC machined parts. Our services include anodizing, electroplating, electrophoretic coating, sandblasting, polishing, baking, chemical conversion coating, passivation, blackening, and QBQ protection. Each process is backed by professional testing, including film thickness, hardness, color consistency, corrosion resistance, and adhesion, ensuring your components meet the strictest industry standards. These finishes enhance durability, aesthetics, and functional performance, making your parts ready for aerospace, automotive, medical, and industrial applications.

Electroplating

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing

Enhances corrosion resistance and surface hardness while adding color for improved durability and appearance.

Polishing

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

Sand Blasting

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

Tumbling

Tumbling smooths and polishes small parts by friction and abrasion in a barrel, offering a consistent but slightly textured finish.

Electropolish

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Electroplating

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

What is 5-Axis CNC machining?

5-axis CNC machining combines three linear axes (X, Y, Z) with two rotary axes (A/B or C), allowing the tool or workpiece to move in five directions simultaneously. This advanced configuration enables the machining of complex geometries in a single setup, greatly improving accuracy and efficiency.

By continuously tilting and rotating the part, 5-axis machining minimizes repositioning errors and ensures optimal tool angles for smooth 3D surfaces — ideal for manufacturing impellers, turbine blades, medical implants, and aerospace components.

The result is superior surface finish (up to Ra 0.1 μm), tight tolerances, and shorter lead times, making it the preferred solution for multi-sided, precision-critical parts.

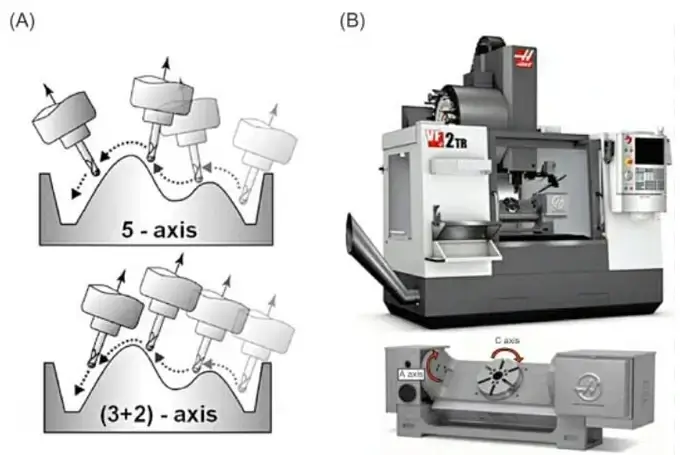

Difference Between Simultaneous 5-Axis and 3+2-Axis CNC Machining

Motion Principle:

- 5-Axis Machining:

All five axes (X, Y, Z plus two rotary axes) move simultaneously and continuously, allowing real-time multi-directional toolpath control. The cutting tool can approach the workpiece from any orientation, making it ideal for machining complex free-form surfaces such as turbine blades, impellers, and medical implants.

- 3+2-Axis Machining:

Also known as positional 5-axis machining, it uses three linear axes for cutting while the two rotary axes lock the workpiece at fixed angles (e.g., a 30° tilt) before machining begins. During cutting, the rotary axes remain stationary, providing excellent accuracy and rigidity for multi-face machining with fewer setups.

Advantages of 5-Axis CNC Milling

1. Complex Geometries – Precisely machine intricate shapes and free-form surfaces from any angle, ideal for aerospace components, automotive parts, and medical implants, reducing multiple setups and simplifying production.

2. Enhanced Accuracy – Minimizes repositioning errors to achieve tight tolerances, ensuring dimensional stability for high-precision industrial, aerospace, and medical applications.

3. Superior Surface Finish – Optimized tool orientation maintains ideal cutting angles, delivering smooth finishes (Ra ≤0.8μm) and reducing secondary finishing for precision automotive, aerospace, and electronic components.

4. Optimized Tool Use – Shorter cutting tools minimize deflection and vibration, producing precise cuts and extending tool life, critical for high-performance metals like titanium, aluminum alloys, and superalloys.

5. Increased Productivity – Combines multiple machining operations into a single setup, reducing lead times and boosting throughput for low- to high-volume production across industrial, automotive, and medical sectors.

6. Material Efficiency – Advanced toolpaths and precise control reduce material waste, essential when working with high-value metals for aerospace, automotive, or energy industry parts.

Applications of 5-Axis CNC Machining

1. Automotive: Custom transmission gears, engine mounts, and intricate hub assemblies. 5-axis machining handles deep pockets and complex features with precision, ideal for both prototype validation and production runs.

2. Medical: Patient-specific implants such as hip joints, cranial plates, and surgical instruments. Achieve precise geometries, smooth surfaces, and biocompatible tolerances for demanding medical applications.

3. Die & Mold Making: Injection molds, stamping dies, and precision fixtures with complex contours and tight tolerances. Perfect for low-volume runs or full-scale production.

4. Marine: Propellers, hull fittings, and structural components designed for durability and accuracy in harsh marine environments.

5. Energy: Wind turbine hubs, solar panel frames, and other power generation components requiring high precision, structural integrity, and long-term reliability.

6. Aerospace: Turbine disks, compressor blades, and airframe structures. 5-axis CNC machining enables complex shapes, multi-sided operations, and consistent quality for high-performance aerospace parts.

5-Axis CNC Machining FAQ

ZH Precision specializes in high-precision 5-axis CNC machining, delivering complex parts with tight tolerances for aerospace, automotive, medical, and industrial applications. This FAQ section answers common questions about our 5-axis CNC capabilities, materials, benefits, and quality control, helping you understand how we can meet your custom machining needs efficiently.

A: It moves the tool or workpiece along five axes (X, Y, Z + 2 rotary axes) to machine complex 3D parts in a single setup, reducing errors and improving accuracy and surface finish.

A: Aerospace, automotive, medical, energy, marine, and precision industrial equipment. Ideal for turbine blades, engine parts, medical implants, and complex molds.

A: Multi-sided machining in one setup, high precision, tight tolerances, superior surface finish, reduced setup time, and ability to handle intricate geometries.

A: Metals including aluminum, stainless steel, mild steel, titanium, copper, brass, and superalloys, with consistent quality and tight tolerances.

A: Full-dimensional inspections, 3D model verification, and strict tolerance checks. FMEA and PFMEA analysis guide the process to guarantee reliable, precise parts.