Custom Aluminum Die Casting Services

ZH Precision is ISO 9001:2015 and IATF 16949:2016 certified, providing high-quality custom aluminum die casting services for global manufacturing industries. With advanced die casting machines ranging from 180T to 1650T, we specialize in producing complex aluminum components with superior dimensional accuracy and smooth surface finishes.

Custom Aluminum Die Casting Parts Manufacturer

ZH Precision is a leading aluminum die casting factory in China, specializing in high-precision aluminum parts for the automotive, energy, and industrial sectors. We integrate mold design, die casting, machining, and surface treatment to deliver consistent quality and fast lead times.

ZH Precision Die Casting Equipment

- 2 – 88 Ton LK Zinc Hot chamber Die Cast Machines

- 1 – 138 Ton RUIDA Zinc Hot chamber Die Cast Machines

- 1 – 280 Ton LK Aluminum cold chamber Die Cast Machine

- 1 – 300 Ton HAITIAN Aluminum cold chamber Die cast machine

- 1 – 400 Ton Aluminum cold chamber Die Cast Machine

- 1 – 500 Ton TOYO Aluminum cold chamber Die Cast Machine

- 1 – 800 Ton LK Aluminium cold chamber Die Cast Machine

- 1 – 1100 Ton UB Aluminum cold chamber Die Cast Machine (Fully Automatic)

- 1 – 1650 Ton YIZUMI Aluminum cold chamber Die Cast Machine

ZH Precision Aluminum Die Casting Capabilities

ZH Precision offers expert aluminum die casting services, producing high-precision, durable components for automotive, electronics, and industrial applications with strict ISO/IATF-certified quality control.

| Description | Specification |

|---|---|

| Maximum Part Weight | 18 kg |

| Minimum Part Weight | 0.005 kg |

| Minimum Part Size | ∅15 mm × 3 mm |

| Maximum Part Size | 350 mm × 720 mm |

| Minimum Wall Thickness | 0.8 mm |

| Maximum Wall Thickness | 15 mm |

| Quality Control | ISO 9001:2015 and IATF 16949:2016 Certified |

| Minimum Possible Batch | 500 pcs |

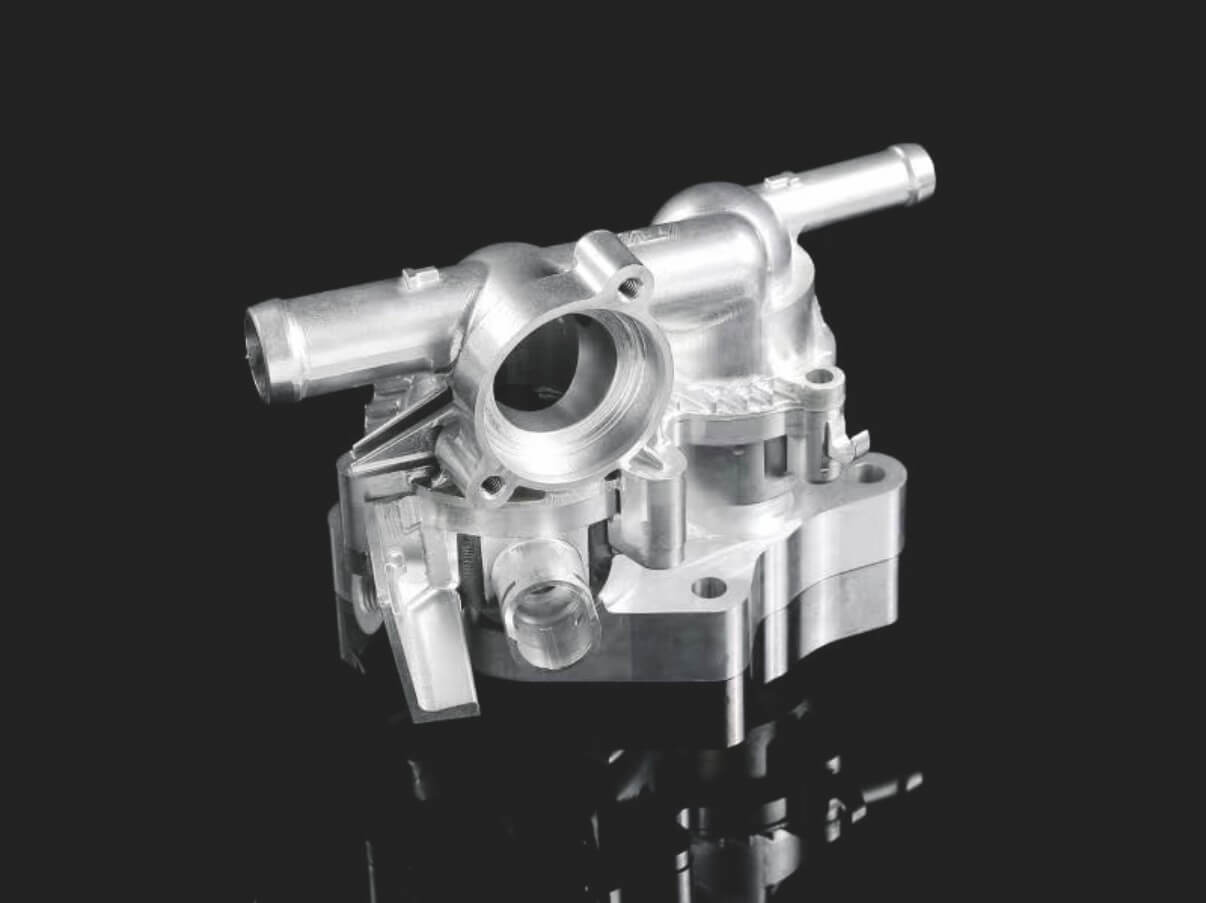

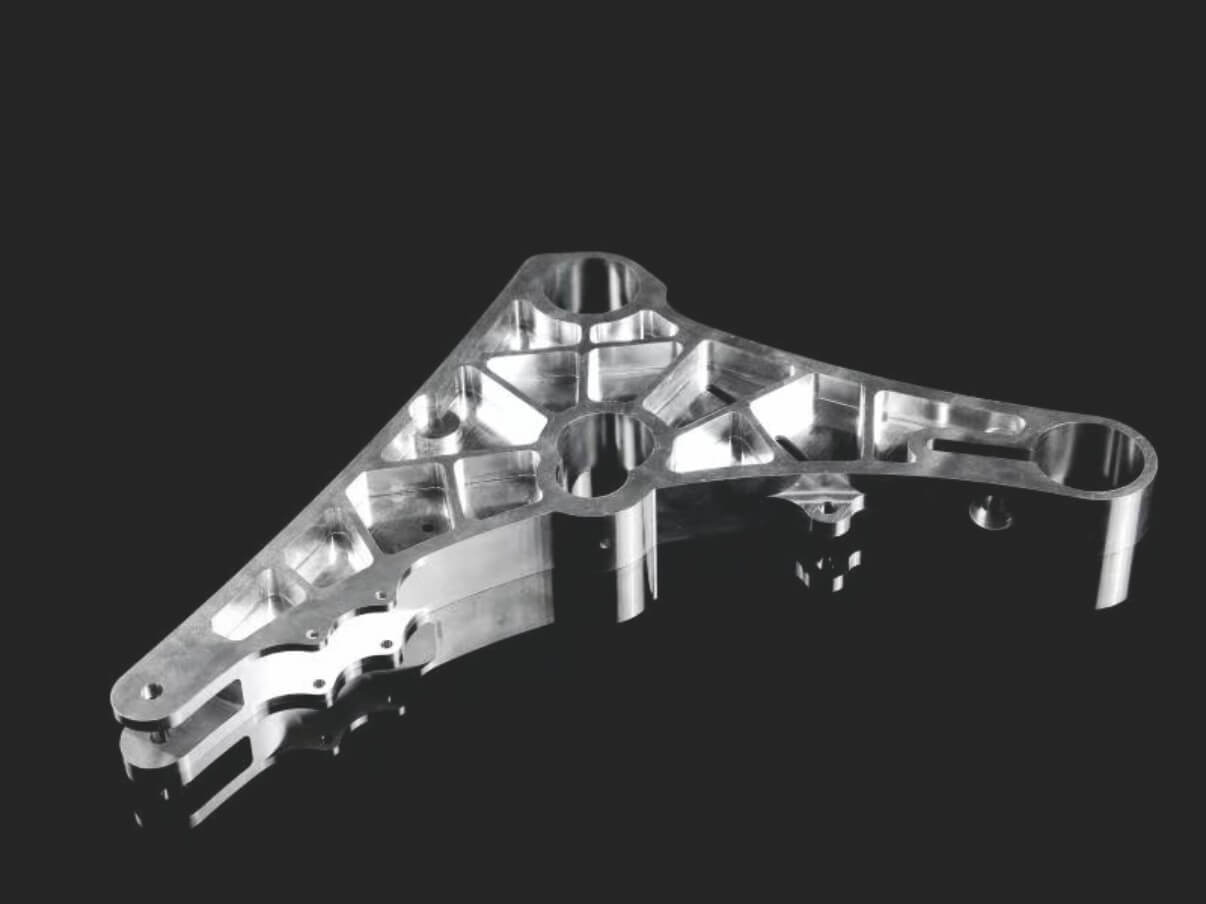

Custom Aluminum Die Cast Parts Gallery

Discover ZH Precision’s custom aluminum die cast parts, highlighting precise tolerances, durable performance, and complex designs for automotive, electronics, and industrial applications.

One-Stop Custom Aluminum Die Casting Manufacturer

ZH Precision offers comprehensive aluminum die casting services, delivering high-precision, durable components across automotive, electronics, industrial, and medical sectors. Our end-to-end capabilities include:

Design & DFM Optimization

Precision Mold Fabrication

High-Performance Aluminum Die Casting

Deburring & Cleaning

Secondary CNC Machining

Surface Finishing

ZH Precision: How Do We Control Your Die-Cast Parts?

At ZH Precision, quality and on-time delivery come first. We maintain full process control—from mold design to final inspection—to ensure each aluminum die-cast part meets your exact specifications and reliability standards.

Quality System

Process Control

Quality Inspection

Aluminum Die-Casting Material

ZH Precision offers a wide range of aluminum die casting materials, including Aluminum ADC06, ADC12, A360, A380, A383, LM06, and HH334R. These alloys provide excellent castability, high strength, dimensional stability, and corrosion resistance. We can also customize aluminum materials to meet specific project requirements, ensuring optimal performance and reliability for automotive, electronics, industrial, and precision parts applications.

Aluminum Alloy

Aluminum die casting

Lightweight, corrosion-resistant, good strength-to-weight ratio. Used for complex, thin-walled car parts, airplane parts, and electronics.

- ADC06

- ADC12

- A360

- A380

- A383

- LM06

- HH334R

Pros and Cons of Aluminum Die Casting

Pros:

- Fast Production: Ideal for high-volume runs with quick cycle times.

- Smooth Surface Finish: High-quality surfaces straight from the mold.

- Precision & Accuracy: Tight tolerances up to ±0.01 mm for complex parts.

- Complex Geometries: Supports intricate designs and thin-walled components.

- Cost-Effective for Large Batches: Lower per-unit costs for mass production.

Cons:

- High Initial Cost: Tooling and mold setup require significant investment.

- Material Limitations: Works only with select aluminum alloys.

- Size Limits: Part dimensions and weight are constrained by die casting equipment.

- Porosity Risks: Air bubbles may affect mechanical strength if not controlled.

- Design Constraints: Wall thickness and draft angles must be carefully planned.

What is Aluminum Die Casting?

Aluminum die casting is a manufacturing process used to make metal parts by forcing molten aluminum into a mold under high pressure. Once the metal cools and solidifies, it takes the exact shape of the mold, creating parts with smooth surfaces and precise dimensions.

This process is perfect for producing large quantities of strong, lightweight parts—such as motor housings, heat sinks, and structural components. It is commonly used in the automotive, electronics, lighting, and industrial sectors.

Aluminum die casting offers many advantages, including excellent strength-to-weight ratio, good corrosion resistance, and the ability to create complex shapes in one process. At ZH Precision, we use high-quality alloys like ADC12 and A380 to ensure durability and consistent performance in every part we produce.

Applications of Aluminum Die Casting

ZH Precision’s aluminum die castings are widely used across industries for their strength, durability, and cost-effectiveness. Our precision casting process produces high-quality components suitable for demanding applications.

- Automotive Parts: Engine blocks, transmission cases, stators, forks, and heat sinks, engineered for high strength, lightweight performance, and precise tolerances.

- Aerospace Components: Fuselage frames, wing spars, and structural parts requiring a high strength-to-weight ratio and reliable dimensional accuracy.

- Industrial Machinery: Gears, pulleys, sprockets, pump covers, and brackets, crafted for durability and precise fit in complex assemblies.

- Electrical Components: Switchgear housings, transformer cases, and junction boxes, leveraging aluminum’s excellent conductivity and non-magnetic properties.

- Consumer Products: Decorative hardware, furniture, and architectural accents, combining aesthetic appeal with robust performance.

- Recreational Equipment: Boat hulls, snowmobile frames, and structural components, designed for reliability and precision under dynamic conditions.

CNC Milling Services FAQ

ZH Precision provides high-precision CNC milling services for a variety of industries, including automotive, aerospace, and medical. This FAQ section answers common questions about materials, tolerances, surface finishes, and complex part capabilities, helping you understand our expertise and ensure reliable, on-time delivery of custom CNC milled parts.

A:ZH Precision provides CNC milling solutions for automotive, aerospace, medical, electronics, and industrial equipment sectors, delivering high-precision, custom components for diverse applications.

A: Yes, we hold ISO 9001 and IATF 16949 certifications, ensuring that automotive CNC milled components meet strict quality and compliance standards.

A: We implement strict quality control through 3D model verification, full-dimensional measurement, FMEA/PFMEA analysis, and in-process inspections to guarantee accuracy and consistency.

A: Yes, our advanced 3-, 4-, and 5-axis CNC milling machines allow us to manufacture complex multi-face geometries, curved surfaces, and intricate features in a single setup.

A: We provide sandblasting, anodizing, electroplating, passivation, coating, polishing, and stress relief to enhance both aesthetics and functional durability.