Custom CNC Machining Services

ZH Precision provides custom CNC machining services for parts produced according to customer drawings and technical requirements. Using CNC milling, CNC turning, and multi-axis machining, we manufacture components in specified materials to support diverse engineering and manufacturing applications.

- Specification-Driven Machining

- Repeatable Production Quality

- Tight Tolerance Control

Verify Certifications On Demand:ISO 9001:2015 | IATF 16949:2016

Home » CNC Machining

Get a Free DFM Quote

STP I SLDPRT I IPT I PRT I SAT FLES

All uploaded content is secure and confidential.

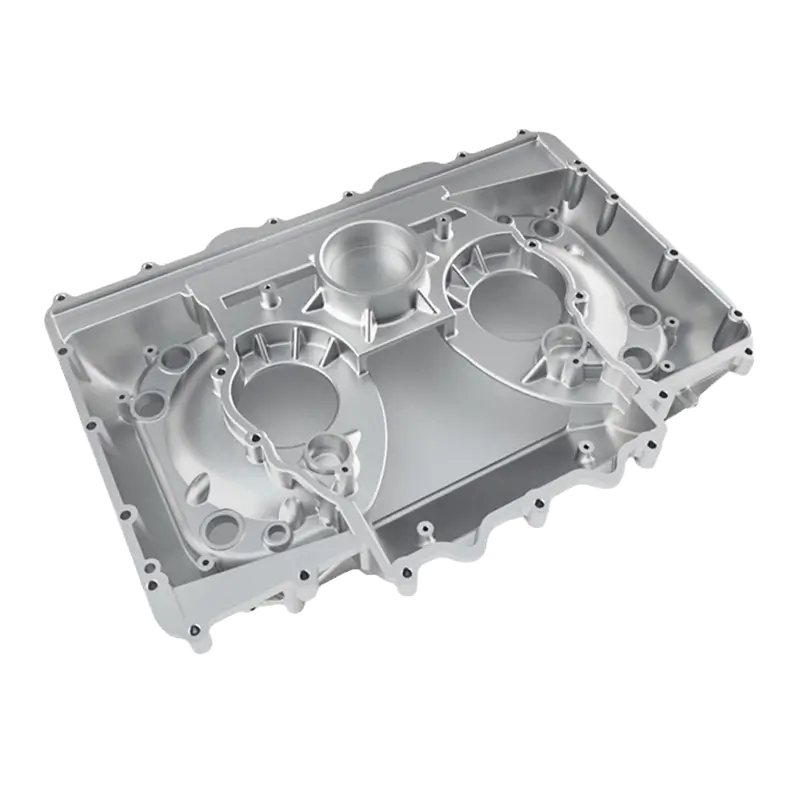

CNC Machining Capabilities for Precision Parts

With advanced CNC milling and turning capabilities, ZH Precision supports diverse part designs and technical requirements. We focus on delivering precision, functional reliability, and dependable lead times, with most orders shipped to North America and Europe within 5–10 business days.

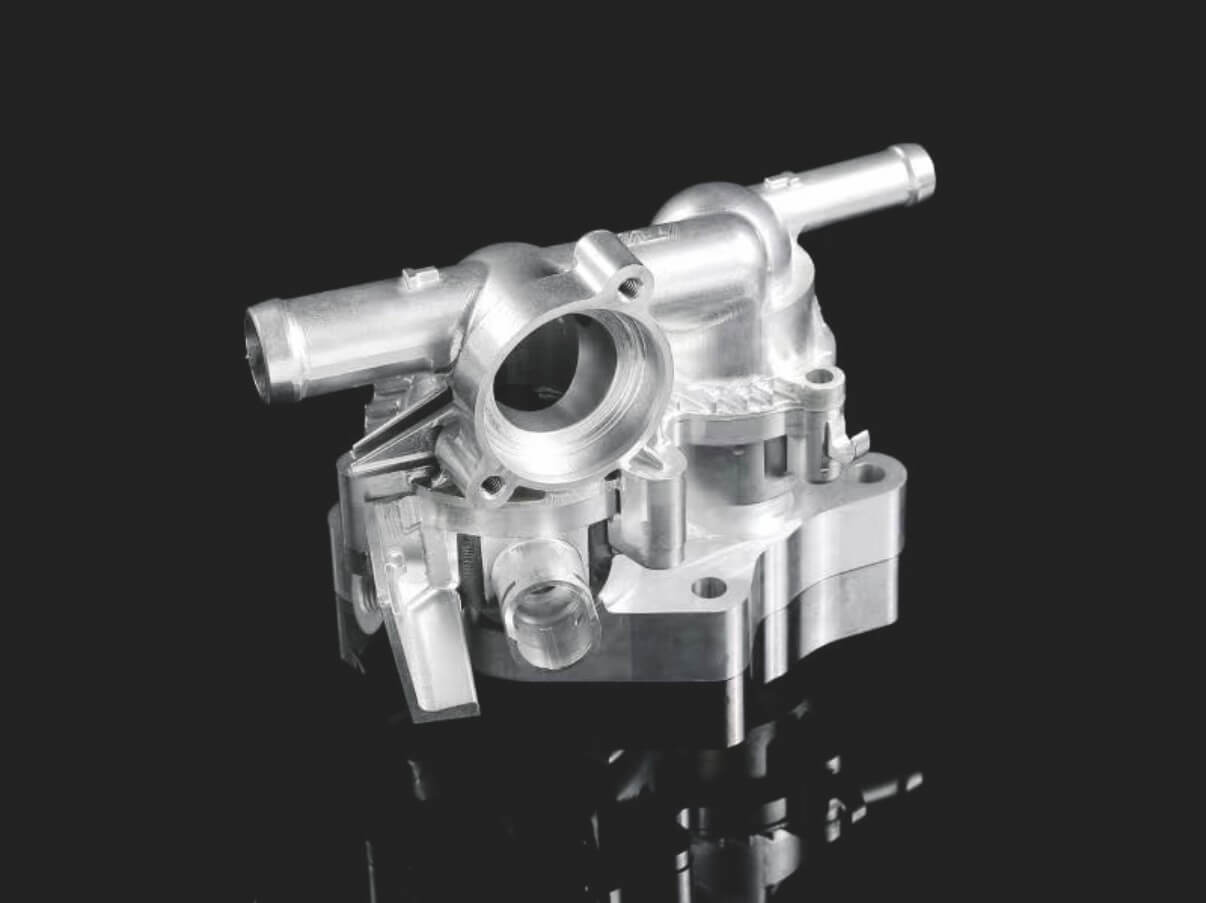

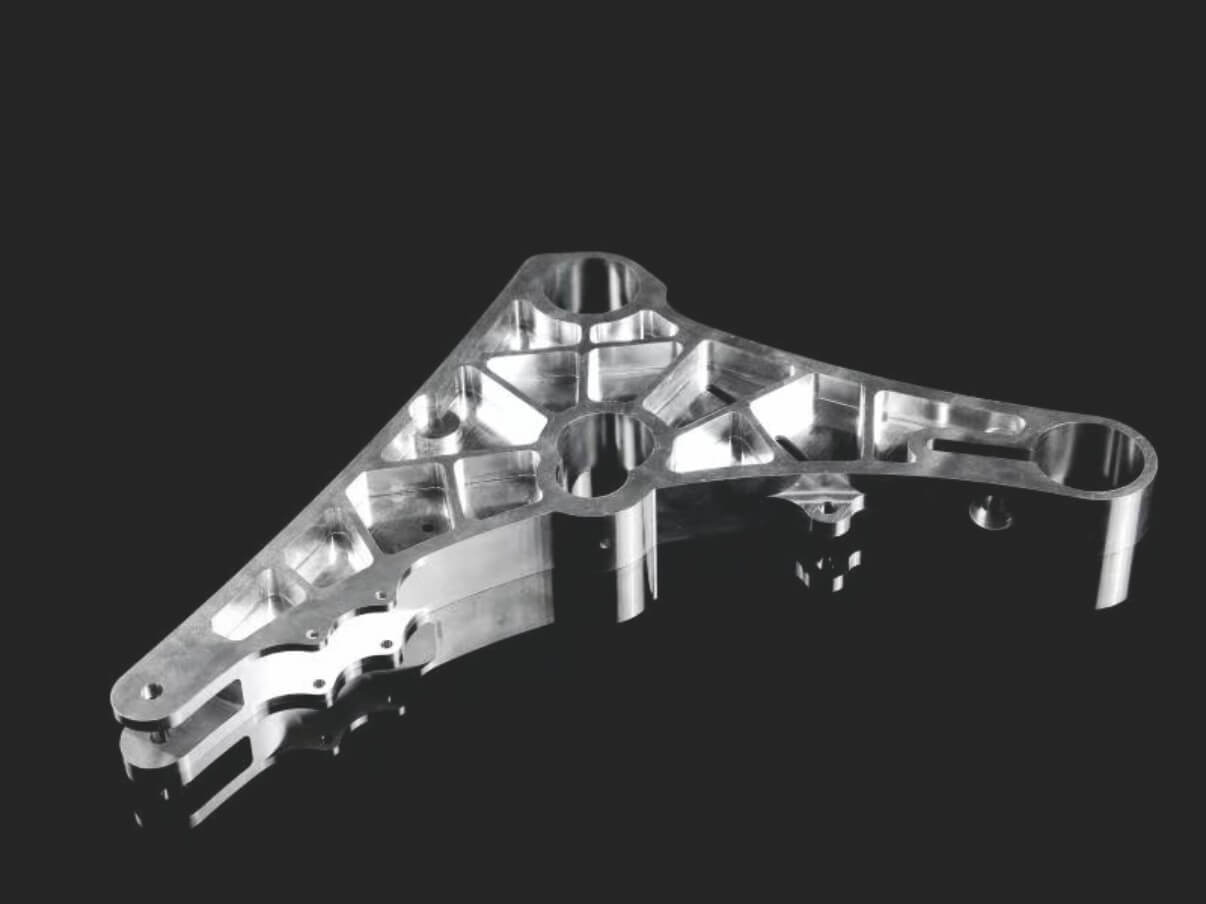

CNC Milling Services

We offer CNC milling for metal parts of all sizes and shapes. Multi-surface machining and flexible batch options ensure parts are produced efficiently to your specifications.

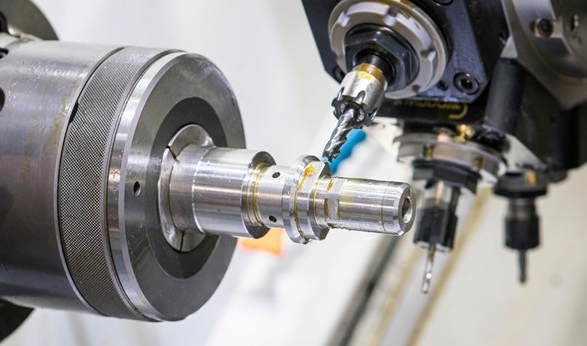

CNC Turning Services

Our CNC turning services deliver precise metal components with consistent dimensions. We handle small and medium batch production for both prototypes and production parts.

CNC Machining Solutions for Prototypes and Production

ZH Precision applies its CNC machining expertise to meet a wide range of project requirements. Our team maintains adaptable processes, strict quality standards, and efficient production timelines, ensuring every component is manufactured with consistency and precision from concept to completion.

Rapid Prototyping

Our CNC prototyping services enable quick evaluation of part designs, helping engineers test functionality and refine designs without delaying project schedules. Fast turnaround and accurate machining provide confidence in prototypes before moving into larger production runs.

Explore Prototyping ServicesLow-Volume Manufacturing

For projects requiring smaller quantities, ZH Precision delivers consistent quality and tight tolerance control. This service supports pilot production, custom components, and bridge manufacturing runs, ensuring repeatable performance while keeping lead times short and predictable.

Exploring Low-Volume Manufacturing ServicesTolerances for CNC Machining

For metal parts, CNC machining tolerances are applied according to ISO 2768-m unless otherwise specified. Tighter tolerances can be specified for specific features and are reviewed before production.

| Specification | Details |

|---|---|

| Maximum Part Dimensions |

Milling: up to 4000 × 1500 × 600 mm Turning: up to 200 × 500 mm |

| Minimum Part Size | 1 × 1 mm |

| Minimum Feature Size | Φ 0.50 mm |

| Linear Dimensions | ±0.025 mm |

| Standard Tolerances | ±0.01 mm (ISO 2768-m) |

| Shaft Diameters | ±0.025 mm |

| Minimum Wall Thickness | 0.5 mm |

| Minimum Tool Diameter |

End mill: 0.5 mm Drill: 1 mm |

| Non-Reamed Hole Tolerance | ±0.02 mm |

| Surface Finish |

As-machined: 125 Ra or better Optional finishing on request |

| Standard Lead Time | Typically 3 business days |

CNC Machining Materials

ZH Precision offers a comprehensive range of CNC machining metal materials, including aluminum alloys, carbon steel, stainless steel, and copper alloys, to meet a wide variety of part requirements in strength, weight, corrosion resistance, and thermal or electrical conductivity. All materials are machined precisely according to customer drawings and technical specifications. If you are uncertain which material is best suited for your project, our engineers can provide expert recommendations to ensure the most cost-effective and reliable solution.

Aluminum Alloy

Aluminum alloys are lightweight, strong, and highly machinable, with excellent corrosion resistance and superior thermal and electrical conductivity. They are ideal for aerospace, automotive, electronics, medical devices, and consumer products.

Stainless Steel

Stainless steel alloys provide high tensile strength, excellent corrosion and temperature resistance, and good ductility. They are easy to weld, machine, and polish, making them ideal for aerospace, automotive, medical devices, and industrial applications.

Copper

Copper provides excellent thermal and electrical conductivity, making it ideal for electrical components such as busbars and wire connectors. Its natural reddish-orange color and glossy finish also make it suitable for decorative and functional applications.

Titanium

Titanium is a lightweight metal with an excellent strength-to-weight ratio, low thermal expansion, and high corrosion resistance. Its biocompatibility and sterilizability make it ideal for aerospace, automotive, and medical applications.

Mild Steel

Mild steel is a low-carbon alloy with good mechanical strength, high stiffness, and excellent machinability and weldability at low cost. It can be carburized to increase surface hardness, making it ideal for industrial, structural, and general manufacturing applications.

Superalloy

Superalloys offer exceptional high-temperature strength, excellent oxidation and hot corrosion resistance, and superior fatigue and fracture toughness. They are primarily used in aerospace and energy applications where extreme conditions demand reliable performance.

Brass

Brass provides excellent wear resistance, high strength and hardness, and strong chemical corrosion resistance. It is ideal for components such as valves, gears, and precision parts like watch movements.

Alloy steel

Alloy steel provides high strength, excellent toughness, and superior wear and corrosion resistance. It performs reliably under extreme temperatures and can exhibit magnetic properties, making it ideal for industrial and structural applications.

Surface Finishing for CNC Machined Parts

ZH Precision provides tailored surface finishing for CNC machined parts, including anodizing, powder coating, plating, and polishing. All finishes are inspected for consistent quality and durability, ensuring both functional performance and aesthetic appeal.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing

Enhances corrosion resistance and surface hardness while adding color for improved durability and appearance.

Polishing

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

Sand Blasting

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

Tumbling

Tumbling smooths and polishes small parts by friction and abrasion in a barrel, offering a consistent but slightly textured finish.

Electropolish

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Electroplating

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

CNC Machining Quality Control

ZH Precision strictly follows ISO 9001:2015. Our quality inspection team uses advanced tools, including height gauges, profile projectors, CMMs, and Olympus metal testers, to ensure every part is thoroughly inspected. This allows us to deliver precise and reliable prototypes and high-precision custom components across industries.

1. Material Verification

All incoming materials undergo strict verification to ensure they meet project specifications and industry standards.

2. Precision Machining Oversight

Our experienced machining team maintains tight tolerances and consistent adherence to design specifications throughout the production process.

3. Final Inspection & Verification

Every finished part undergoes 100% dimensional, surface, and functional inspection, ensuring full compliance with customer requirements and ready-to-ship quality.

Why Choose ZH Precision for CNC Machining

Selecting the right CNC machining provider is essential for cost efficiency, process consistency, and long-term reliability. At ZH Precision, we focus on precise CNC machining, strict process control, and clear technical communication to deliver predictable, repeatable, and high-quality results for every project.

Fully Transparent Quoting

We provide fully transparent CNC machining quotes, outlining costs, lead times, and requirements for informed decision-making.

Flexible Production Capabilities

Ability to handle diverse part sizes and materials, adapting quickly to changing project requirements without compromising precision or quality.

Precision & Process Reliability

Robust CNC machining standards and repeatable workflows ensure every component meets strict dimensional and functional requirements.

On-Time Delivery & Scalability

Efficient scheduling and reliable lead times, with the capacity to scale from small runs to larger production, keeping projects on track.

Frequently Asked Questions

A: CNC machining is a manufacturing process that uses computer-controlled machines to cut, mill, and turn metal. It enables high-precision and efficient production of complex parts, widely used in aerospace, electronics, automotive, and medical industries. Learn more about CNC machining in our blog

A: The CNC Machining DFM (Design for Manufacturability) guide helps engineers optimize parts during the design phase to reduce machining complexity and cost. Key considerations include uniform wall thickness, hole placement, fillet design, tolerance control, and avoiding deep holes or fine features. Learn more about CNC DFM design tips in our blog

A: CNC machining can be performed on a wide range of metals, including aluminum, steel, stainless steel, copper, and titanium alloys. Material selection should consider part strength, wear resistance, corrosion resistance, and required machining accuracy.

A: Standard CNC machining tolerances are typically ±0.01mm, while high-precision 5-axis machining can achieve ±0.005mm. Actual tolerances depend on the material, part size, and machining process.

A: Yes. With multi-axis (3-axis, 4-axis, or 5-axis) machining, CNC machines can produce complex surfaces, holes, grooves, and fine features, making them ideal for functional prototypes and precision parts.